Electrode material, lithium ion battery and preparation method and application thereof

An electrode material, lithium ion technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of small average diameter, battery capacity retention rate, rate performance and cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

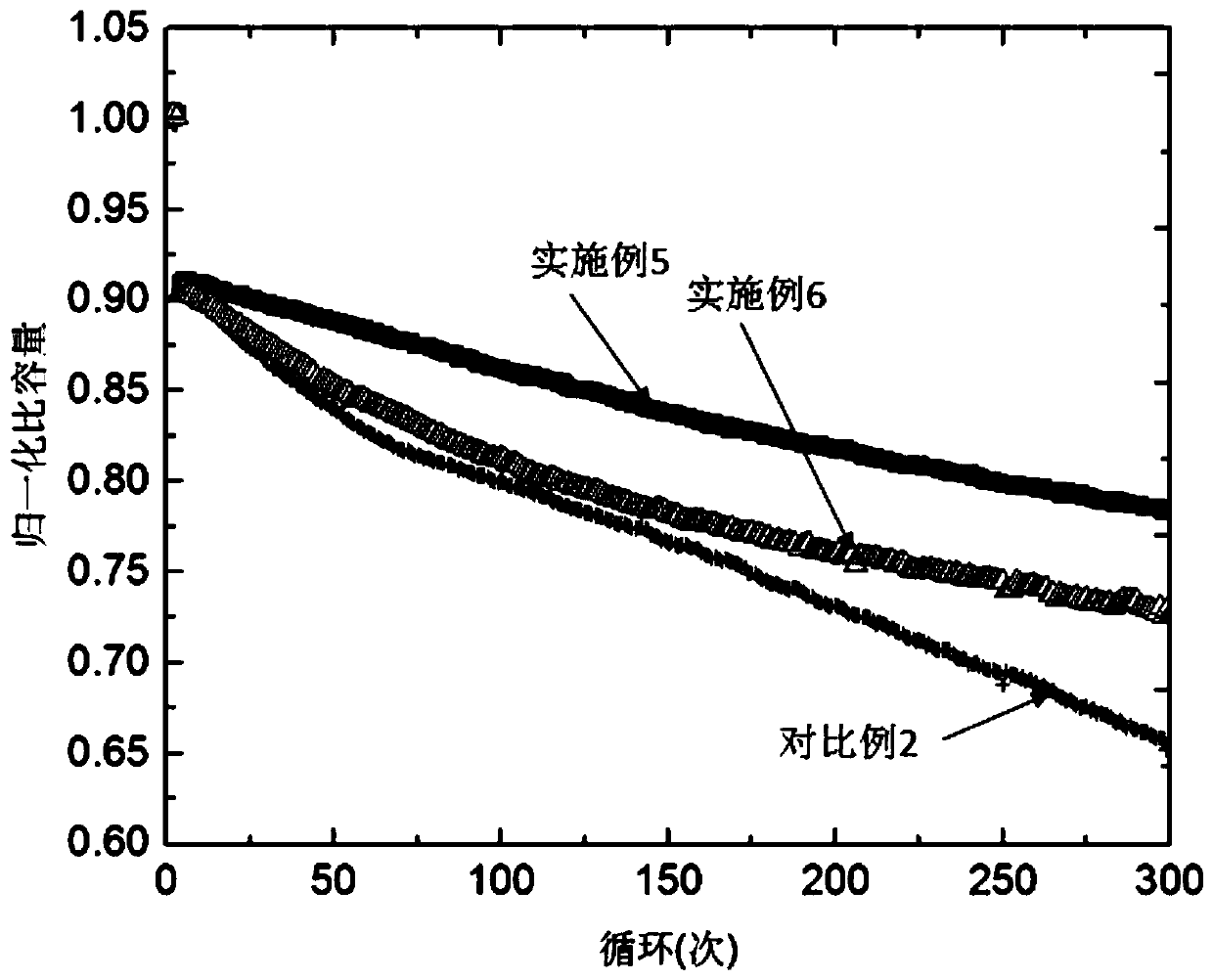

Examples

Embodiment 1

[0073] (9.2g, 0.1mol) precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 , (9.7g, 0.1mol) seed LiNi 0.6 co 0.2 mn 0.2 o 2 , (4.72g, 0.2mol) LiOH, (11.69g, 0.2mol) NaCl were mixed evenly, put into a corundum crucible, heated to 900°C at a heating rate of 10°C / min, kept for 10 hours, and naturally cooled to room temperature, The mixture was washed three times with deionized water to remove the molten salt, dried in vacuum at 120°C for 3 hours, then placed in a crucible, heated to 750°C at a heating rate of 10°C / min, kept for 6 hours, and naturally cooled to room temperature to obtain the product 1, its chemical formula is LiNi 0.6 co 0.2 mn 0.2 o 2 .

[0074] Wherein, the elemental analysis of the precursor of Example 1 and product 1 is as follows.

[0075] Elemental analysis (ICP) results

[0076] Example 1

Embodiment 2

[0078] (9.2g, 0.1mol) precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 , (0.97g, 0.01mol) seed LiNi 0.6 co 0.2 mn 0.2 o 2 , (2.9g, 0.121mol) LiOH, (6.43g, 0.11mol) NaCl were mixed evenly, put into a corundum crucible, heated to 900°C at a heating rate of 10°C / min, kept for 10 hours, and naturally cooled to room temperature, The mixture was washed three times with deionized water to remove the molten salt, dried in vacuum at 120°C for 3 hours, then placed in a crucible, heated to 750°C at a heating rate of 10°C / min, kept for 6 hours, and naturally cooled to room temperature to obtain the product 2, its chemical formula is LiNi 0.6 co 0.2 mn 0.2 o 2 .

Embodiment 3

[0080] (9.2g, 0.1mol) precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 , (9.7g, 0.1mol) seed LiNi 0.8 co 0.1 mn 0.1 o 2 , (4.72g, 0.2mol) LiOH, (11.69g, 0.2mol) NaCl were mixed evenly, put into a corundum crucible, heated to 900°C at a heating rate of 10°C / min, kept for 10 hours, and naturally cooled to room temperature, The mixture was washed three times with deionized water to remove the molten salt, dried in vacuum at 120°C for 3 hours, then placed in a crucible, heated to 750°C at a heating rate of 10°C / min, kept for 6 hours, and naturally cooled to room temperature to obtain the product 3. Its chemical formula is LiNi 0.8 co 0.1 mn 0.1 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com