Electrode material surface coating method and application thereof

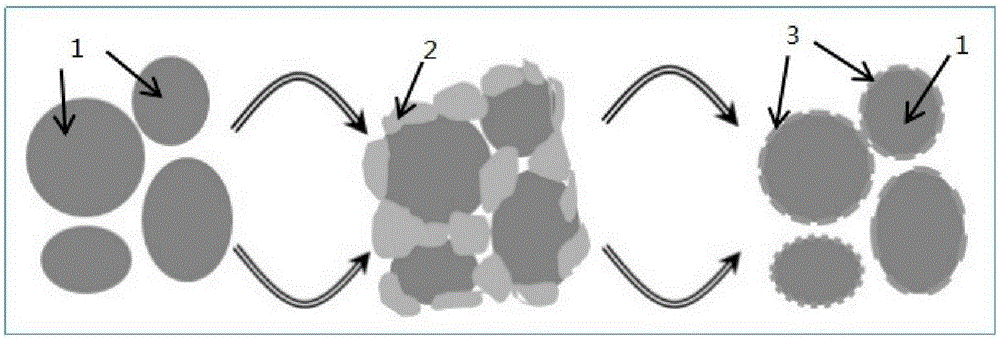

An electrode material and surface coating technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as erosion damage, electrode material side reaction surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

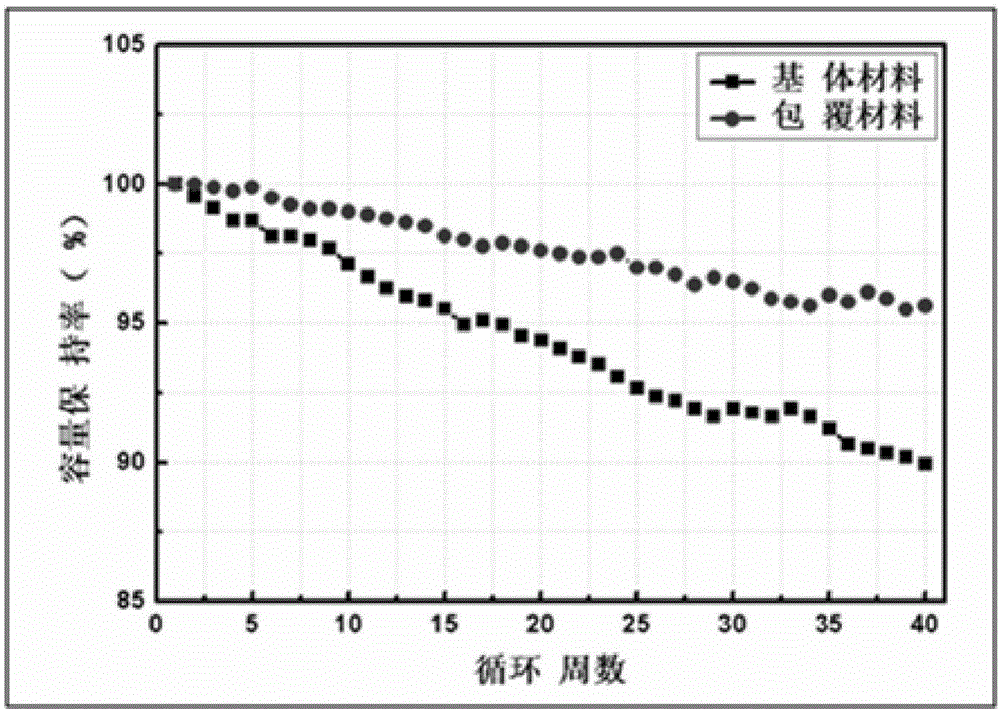

Examples

Embodiment 1

[0063] (1) Synthesize high-nickel NCM (Ni:Co:Mn=8:1:1) precursor by co-precipitation method, mix lithium source (LiOH) according to Li / (Ni+Co+Mn) ratio of 1.05, after sintering Obtain the electrode material LiNi 0.8 co 0.1 mn 0.1 o 2 As a matrix, the matrix material is crushed, sieved and dried before being coated, and collected for future use.

[0064] (2) Weigh DMF and methanol respectively and mix them at a volume ratio of 1:1 to make a uniform solvent. 20g of electrode material LiNi 0.8 co 0.1 mn 0.1 o 2 Add it to the above homogeneous solvent, stir and disperse evenly to obtain a dispersion system.

[0065](3) Take by weighing cobalt nitrate 0.36g and terephthalic acid 0.075g respectively, and join it in the dispersion system that step (2) obtains, ultrasonic 30min, obtain mixed liquor, wherein cobalt nitrate and terephthalic acid molar ratio It is 3:1.

[0066] (4) Transfer the mixed solution of step (3) into a hydrothermal kettle, tighten the seal, place in a c...

Embodiment 2

[0070] (1) Synthesize high-nickel NCA (Ni:Co:Al=0.815:0.15:0.035) precursor by co-precipitation method, mix lithium source (LiOH) according to Li / (Ni+Co+Al) ratio of 1.03, after sintering Obtain the electrode material LiNi 0.15 co 0.15 al 0.035 o 2 As a matrix, the matrix material is crushed, sieved and dried before being coated, and collected for future use.

[0071] (2) Measure 250mL of methanol, weigh 1.4g of magnesium nitrate, add it to methanol, stir and dissolve to obtain a solution, and weigh 100g of electrode material LiNi 0.15 co 0.15 al 0.035 o 2 Add to the above solution, fully disperse to obtain dispersion system I;

[0072] (3) Take another 250 mL of methanol, add 3 g of formic acid into it, stir and mix well to obtain the dispersion system II.

[0073] (4) Pour dispersion system I and dispersion system II into the reaction kettle and mix them, add 3g of triethylamine, shake well, seal, and let stand at room temperature for 24 hours. After the reaction, ta...

Embodiment 3

[0077] (1) Synthesize high-nickel NCM (Ni:Co:Mn=6:2:2) precursor by co-precipitation method, mix lithium source (LiOH) according to Li / (Ni+Co+Mn) ratio of 1.08, after sintering Obtain the electrode material LiNi 0.6 co 0.2 mn 0.2 o 2 as a base.

[0078] (2) Add 400 mg of aluminum nitrate nonahydrate, 300 mg of trimesic acid, 200 mg of sodium hydroxide, and 10 mL of deionized water into a polytetrafluoroethylene reactor, stir until uniform, and obtain a dispersion.

[0079] (3) Add 100g electrode material LiNi to the dispersion system 0.6 co 0.2 mn 0.2 o 2 , fully dispersed evenly to obtain a mixed solution.

[0080] (4) Put the mixed liquid in step (3) into the reaction kettle and move it into an oven at 150°C, react for 48 hours, take it out after cooling, and centrifuge with methanol solvent to obtain the product precursor.

[0081] (5) After completing the above steps, vacuum-dry the product precursor obtained in step (4) at 100°C, then put it into a crucible, put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com