Composite solid electrolyte membrane based on metal-organic framework material as well as preparation method and application of composite solid electrolyte membrane

A technology of solid electrolyte membrane and organic framework, which is applied in the direction of composite electrolyte, electrolyte battery manufacturing, non-aqueous electrolyte battery, etc. It can solve the problems of low conduction efficiency, limited high-voltage electrochemical stability, and insufficient ionic conductivity of solid electrolytes, etc. , to improve ionic conductivity, solve the problem of poor electrochemical stability at high voltage and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A composite solid electrolyte membrane based on a metal-organic framework material comprising:

[0045] A polymer network formed by cross-linking polymerization of polyethylene oxide (PEO) and metal-organic framework (MOF) modified by toluene diisocyanate (TDI); lithium salt dispersed in the polymer network.

[0046]Among them, toluene diisocyanate is used as an intermediate, and the two ends are respectively connected with metal-organic framework materials and polyethylene oxide to form a network structure.

[0047] Preferably, the cross-linked polymerization mode of the polymer network structure is represented by a structural formula, as follows:

[0048]

[0049] Wherein said B and A, B and C are connected by a C-O chemical bond;

[0050] Wherein, A represents a metal-organic framework material group, B represents a toluene diisocyanate group, and C represents a polyethylene oxide group, and their respective structural formulas are as follows:

[0051] A:

[...

Embodiment 2

[0063] The preparation method of the metal-organic framework material (TDI-MOF) modified by toluene diisocyanate comprises the following steps:

[0064] (1) 8mmol Cu(NO 3 ) 2 and 4 mmol of 2,5-dihydroxyterephthalic acid were dissolved in 80 ml of a mixed liquid of N,N-dimethylformamide and absolute ethanol at a volume ratio of 20:1. Then the mixed liquid was heated at 80 °C overnight, the powder was obtained by centrifugation and washed with DMF, and finally the product was vacuum-dried at 150 °C overnight to obtain Cu-MOF-74 material.

[0065] (2) In a glove box filled with argon, disperse TDI and Cu-MOF-74 materials in toluene solvent at a mass ratio of 3:1, MOF is 10% of the solvent mass; heat and stir the mixture at 50 °C 6h, a crosslinking reaction occurs to obtain a metal-organic framework (TDI-MOF) modified with toluene diisocyanate and washed and dried;

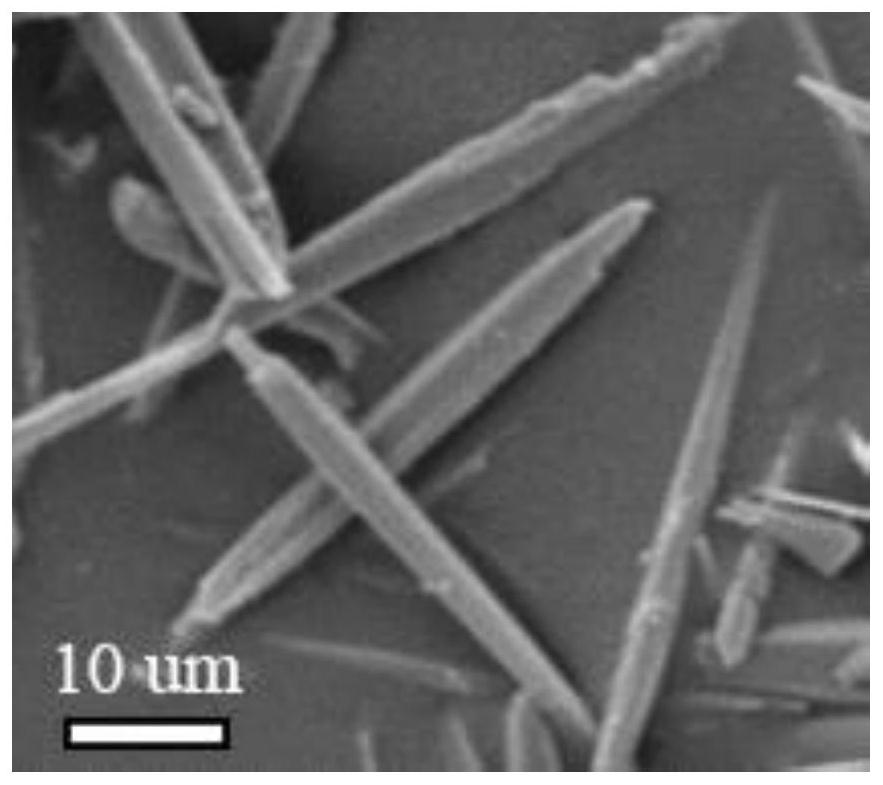

[0066] The obtained toluene diisocyanate modified metal-organic framework (TDI-MOF) was characterized. SEM imag...

Embodiment 3

[0068] A preparation method for a solid electrolyte membrane at room temperature, comprising the following steps:

[0069] (1) In a glove box filled with argon, the TDI-MOF material prepared in Example 2 and LiTFSI lithium salt were dissolved in anhydrous acetonitrile, and ultrasonically dispersed to obtain the first slurry;

[0070] (2) Add polyethylene oxide to the first slurry obtained in step (1), and heat and stir at 50° C. for 5 hours to cause a crosslinking reaction between the TDI-MOF material and PEO to obtain a second slurry.

[0071] (3) The second slurry obtained in step (2) was poured onto a polytetrafluoroethylene template, and dried at 50° C. for 12 hours to obtain a treated PEO-TDI-MOF / LiTFSI composite solid electrolyte membrane.

[0072] Among them, the amount of lithium salt added is according to n(EO) / n(Li + )=20, the TDI-MOF material accounts for 2.5% of the mass of the composite solid electrolyte membrane.

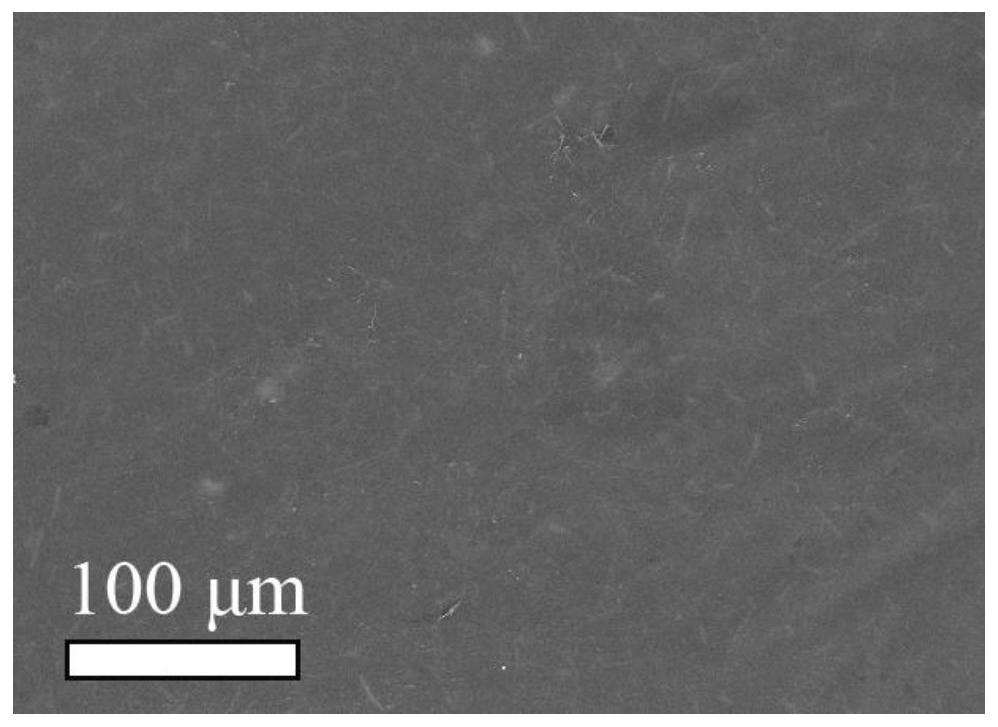

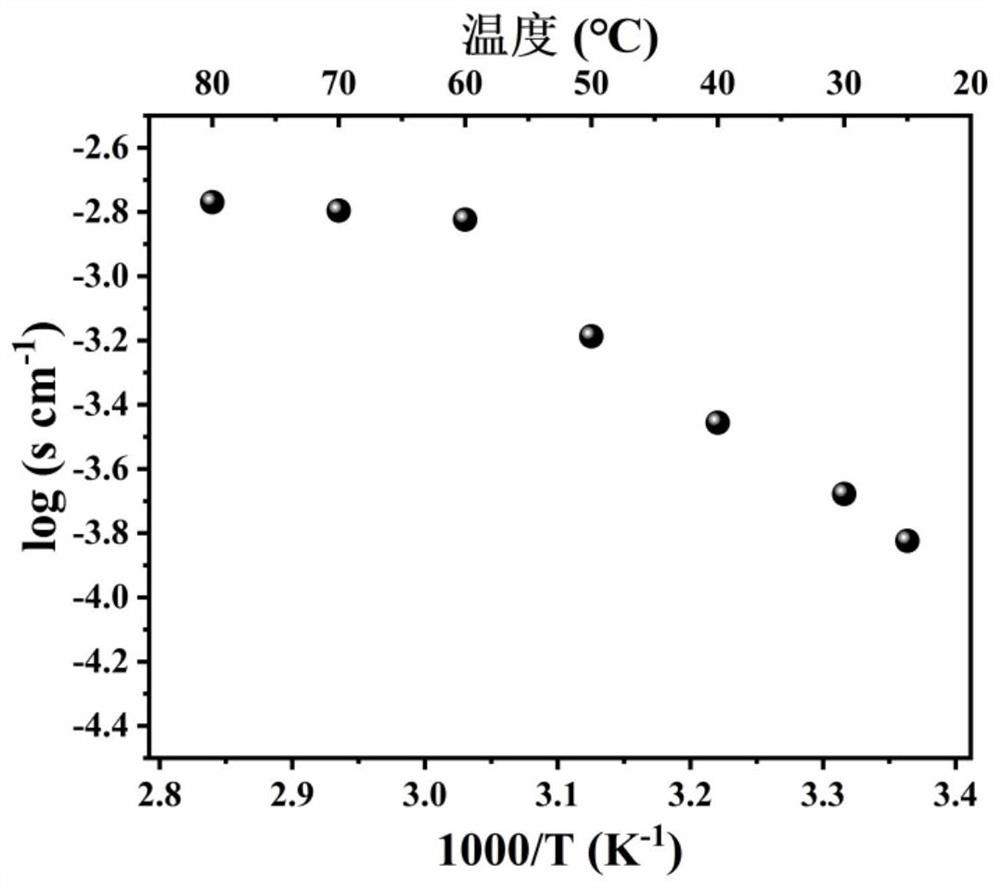

[0073] The above-mentioned composite solid ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com