Modified single-crystal ternary positive electrode material and preparation method thereof

A cathode material and modification technology, applied in the field of modified single crystal ternary cathode materials and their preparation, can solve the problems of complex preparation of oxides or salt solutions, inability to form continuous surfaces, uneven surface of materials, etc., and achieve easy testing. , The effect of small kinetic energy and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment prepares a modified single crystal ternary positive electrode material, including the following steps:

[0048] (1) Weigh Ni at a molar ratio of 1:1.06 0.72 co 0.08 mn 0.2 (OH) 2 and lithium hydroxide, mixed evenly in a 3D mixer, heated up to 880°C at 10°C / min in an oxygen atmosphere, kept for 18 hours, and cooled to below 60°C to obtain the single crystal ternary material LiNi 0.72 co 0.08 mn 0.2 O.

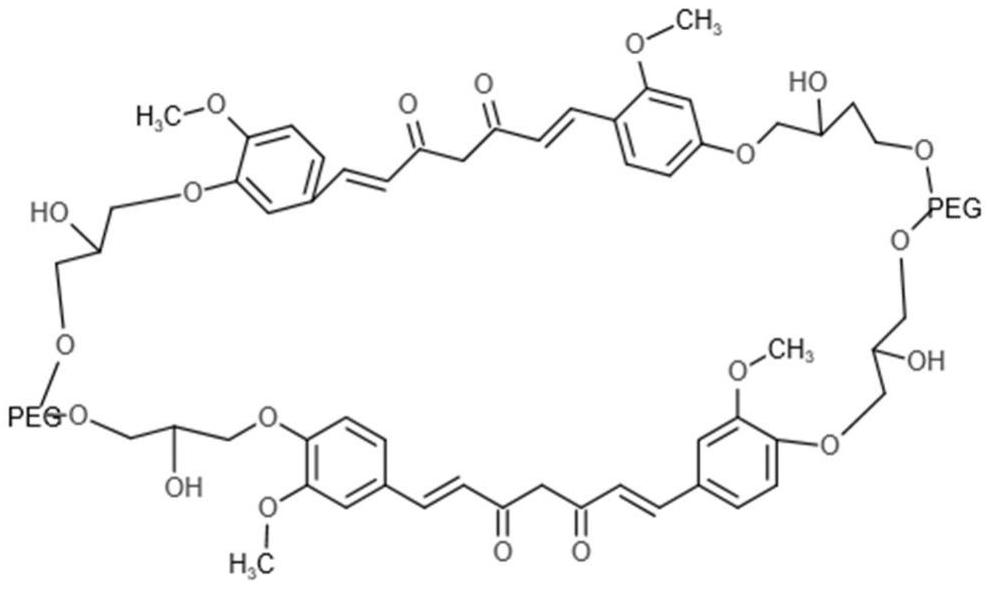

[0049] (2) Take 2g of boron trifluoride ether, 7.6g of propylene oxide and 166.4g of PEG-200 and mix evenly, raise the temperature to 50°C and react for 2.5h; then add 125g of curcumin into the reaction system, and dropwise add ammonia water to adjust the pH to 10.5 , and then continue to heat up to 75 ° C for 2 hours; after the reaction is completed, adjust the pH to 7 with 1mol / L hydrochloric acid solution, and repeatedly wash with isopropanol for 3 to 4 times with suction filtration to obtain curcumin modified dibasic alcohol (M-CP ).

[0050] (...

Embodiment 2

[0054] This embodiment prepares a modified single crystal ternary positive electrode material, including the following steps:

[0055] (1) Weigh Ni at a molar ratio of 1:1.06 0.72 co 0.08 mn 0.2 (OH) 2 and lithium hydroxide, mixed evenly in a 3D mixer, heated up to 880°C at 10°C / min in an oxygen atmosphere, kept for 18 hours, and cooled to below 60°C to obtain the single crystal ternary material LiNi 0.72 co 0.08 mn 0.2 O.

[0056] (2) Mix 2g of boron trifluoride ethyl ether, 4.8g of propylene oxide and 141.6g of PEG-400 evenly, raise the temperature to 50°C and react for 2.5h; then add 84.2g of curcumin into the above reaction system, add dropwise NaOH aqueous solution to adjust pH to 11, then continue to heat up to 75 ° C for 2 hours; after the reaction is finished, adjust the pH to 7 with 1mol / L hydrochloric acid solution, wash repeatedly with isopropanol for 3 to 4 times and suction filter to obtain curcumin modified dibasic alcohol ( M-CP).

[0057] (3) Add 8.7g o...

Embodiment 3

[0061] This embodiment prepares a modified single crystal ternary positive electrode material, including the following steps:

[0062] (1) Weigh Ni at a molar ratio of 1:1.06 0.72 co 0.08 mn 0.2 (OH) 2 and lithium hydroxide, mixed evenly in a 3D mixer, heated up to 880°C at 10°C / min in an oxygen atmosphere, kept for 18 hours, and cooled to below 60°C to obtain the single crystal ternary material LiNi 0.72 co 0.08 mn 0.2 O.

[0063] (2) Mix 2g of boron trifluoride ether, 8.4g of propylene oxide and 160.4g of PEG-600 evenly, raise the temperature to 50°C and react for 2.5h; then add 141.6g of curcumin into the above reaction system, and dropwise add ammonia water to adjust the pH to 10, then continue to heat up to 75 ° C for 2 h; after the reaction is finished, adjust the pH to 7 with 1mol / L hydrochloric acid solution, wash repeatedly with isopropanol for 3 to 4 times and suction filter to obtain curcumin modified dibasic alcohol (M -CP).

[0064] (3) Add 6.26 g of polyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com