Metal lithium wire and preparation method thereof

A technology of metal lithium and lithium salt, which is applied in the field of metal lithium wire and its preparation, can solve the problems of low chemical activity, high surface density of three-dimensional matrix, and lower battery specific energy, so as to alleviate volume change, high specific surface area, and improve practicality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

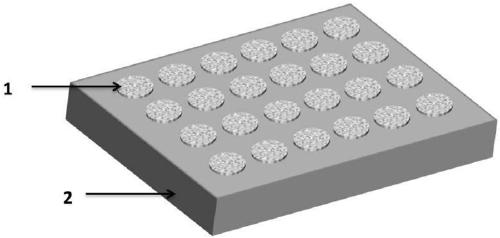

Image

Examples

Embodiment 1

[0032] 1) Place the PDMS-filled cylindrical copper array with a diameter of 5 microns (filled with insulating material, only the upper end surface is exposed) in absolute ethanol, soak for 10 minutes to remove oil, and the copper plate after oil removal is cleaned with deionized water Three times, then dry the residual water with a cooling fan and set aside;

[0033] 2) In a glove box filled with dry argon with a relative humidity of less than 1%, prepare a deposition electrolyte, mix the solvent DOL and DME at a volume ratio of 2:1, add LiTFSI and LiFSI mixed salts to the solvent, The molar concentrations of the two salts in the final solvent are respectively 0.4mol / l and 0.6mol / l, for subsequent use;

[0034] 3) Place the copper array substrate as the working electrode in the organic electrolyte system in 2), maintain the temperature at 30°C, use metal lithium as the counter electrode, and connect the wires;

[0035] 4) Electrochemical deposition of metal lithium wires was ...

Embodiment 2

[0040] 1) Place the PDMS-filled cylindrical ITO array substrate with a diameter of 2 microns (filled with insulating material, only the upper end surface is exposed) in absolute ethanol, soak for 10 minutes to remove oil, and use the ITO conductive array substrate after degreasing. Wash with ion water three times, then dry the residual water with a cooling fan, and set aside;

[0041] 2) In a glove box filled with dry argon with a relative humidity of less than 1%, the deposition electrolyte was prepared, and the solvent DOL, DEGDME and PEGDME were mixed according to the volume ratio of 1:1:1, and the LiPF 6 Join in the solvent, the molar concentration of two kinds of salts in the final solvent is respectively 0.5mol / l, standby;

[0042] 3) Place the ITO conductive array substrate as the working electrode in the organic electrolyte system in 2), maintain the temperature at 60°C, use metal lithium as the counter electrode, and connect the wires;

[0043] 4) Under constant curr...

Embodiment 3

[0047] 1) Put PE-filled cylindrical carbon arrays with a diameter of 10 microns (filling with insulating material, only the upper end surface is exposed) substrate in absolute ethanol, soak for 5 minutes to degrease, degrease the carbon array substrate with deionized Wash with water for three times, then dry the remaining water with a cooling fan, and set aside;

[0048] 2) In a glove box filled with dry argon with a relative humidity of less than 1%, prepare a deposition electrolyte, and mix the solvents ethylene carbonate, diethyl carbonate and dimethyl carbonate in a volume ratio of 1:1:1 , the LiBF 4 and LiBOB lithium salt are added in the solvent, and the molar concentrations of the two salts in the final solvent are respectively 0.8mol / l and 0.4mol / l, for subsequent use;

[0049] 3) Put the carbon array substrate as the working electrode in the organic electrolyte system in 2), maintain the temperature at 40°C, use metal lithium as the counter electrode, and connect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com