Nickel-cobalt-boron precursor material and preparation method, nickel-cobalt-boron positive electrode material

A cathode material and precursor technology, applied in the field of lithium-ion battery materials, can solve the problems of material capacity attenuation, impedance increase, penetration, etc., and achieve the effects of reducing impedance, suppressing polarization, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment includes the following steps:

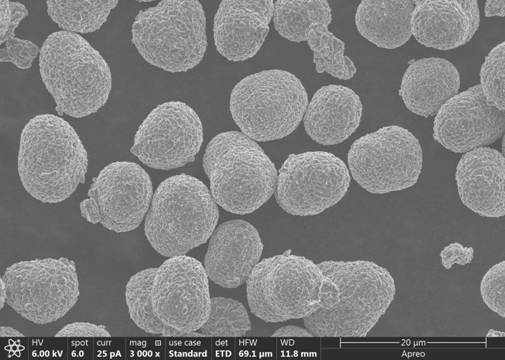

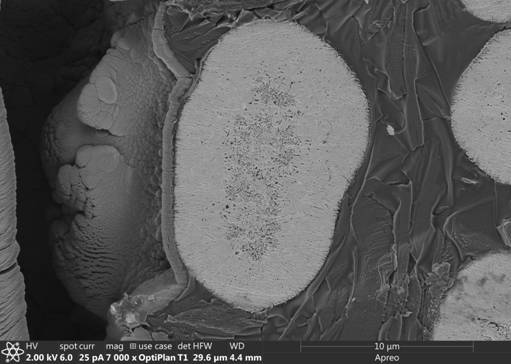

[0047] (1) Preparation of Ni 0.9 Co 0.08 B 0.02 (OH) 2 Precursor

[0048] ①Solution preparation: 118.28 kg of nickel sulfate hexahydrate, 11.25 kg of cobalt sulfate heptahydrate, 0.70 kg of boron oxide and hot pure water were fully mixed and dissolved to prepare 200 L of solution A, the concentration of which was 2.5 mol / L. Molar ratio Ni:Co:B =9.0:0.8:0.2; take 25% industrial ammonia water to configure 7.5 mol / L solution B, the volume is 100 L, and the molar ratio to solution A is 1.5; 32% industrial hydrogen Sodium oxide and distilled water were mixed to prepare 12.5 mol / L solution C, the volume was 100 L, and the molar ratio to solution A was 2.5; solutions A, B, and C were kept at a constant temperature of 40 °C.

[0049] ②Preparation of reaction kettle bottom liquid D: In a 300 L reaction kettle, first add hot pure water to 1 / 2 of the volume of the reaction kettle, control the temperature in the kettle to 50 °C, ...

Embodiment 2

[0060] This embodiment includes the following steps:

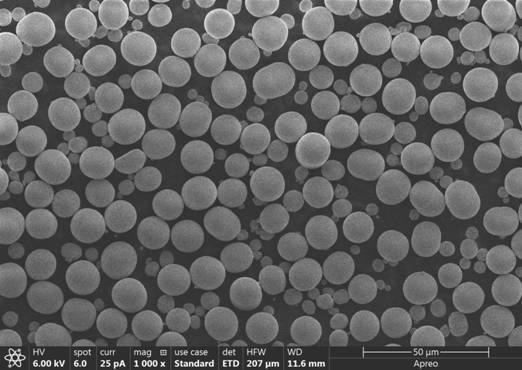

[0061] (1) Preparation of Ni 0.75 Co 0.2 B 0.05 (OH) 2 Precursor:

[0062] ①Solution preparation: 157.71 kg of nickel sulfate hexahydrate, 44.98 kg of cobalt sulfate heptahydrate, 2.78 kg of boron oxide and hot pure water were fully mixed and dissolved to prepare 400 L of solution A, the concentration of which was 2.0 mol / L. Molar ratio Ni:Co:B =7.5:2.0:0.5; take 25% industrial ammonia water to prepare 8.0 mol / L solution B, the volume is 100 L, and the molar ratio to solution A is 1; 32% industrial hydrogen Sodium oxide and distilled water were mixed to prepare 9.6 mol / L solution C, the volume was 100 L, and the molar ratio to solution A was 1.2; solutions A, B, and C were kept at a constant temperature of 45 °C.

[0063] ②Preparation of reaction kettle bottom liquid D: In a 500 L reaction kettle, first add hot pure water to 1 / 2 of the volume of the reaction kettle, control the temperature in the kettle to 55 °C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com