Sodium vanadium fluorophosphate electrode coated with metal oxide layer and preparation method thereof

A technology of sodium vanadium fluorophosphate and oxide layer, which is applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as de-V, and achieve the effects of increasing yield, reducing interface side reactions, and improving capacity retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025]The preparation method of the sodium vanadium fluorophosphate electrode coated with a metal oxide layer of the present invention adopts atomic layer deposition technology and includes the following steps:

[0026]1) The active material Na3V2(PO4)2F3, Conductive carbon black SP, binder, and solvent are mixed in a certain proportion, ball milled, scraped, and dried to obtain spare electrode sheets. The electrode sheets are put into the reaction chamber of the atomic layer deposition system, and the reaction chamber The temperature is adjusted to 150~250℃, and the pressure is adjusted to 20~80Pa.

[0027]2) Perform atomic layer deposition treatment to obtain the Na coated with a metal oxide layer3V2(PO4)2F3Electrode material.

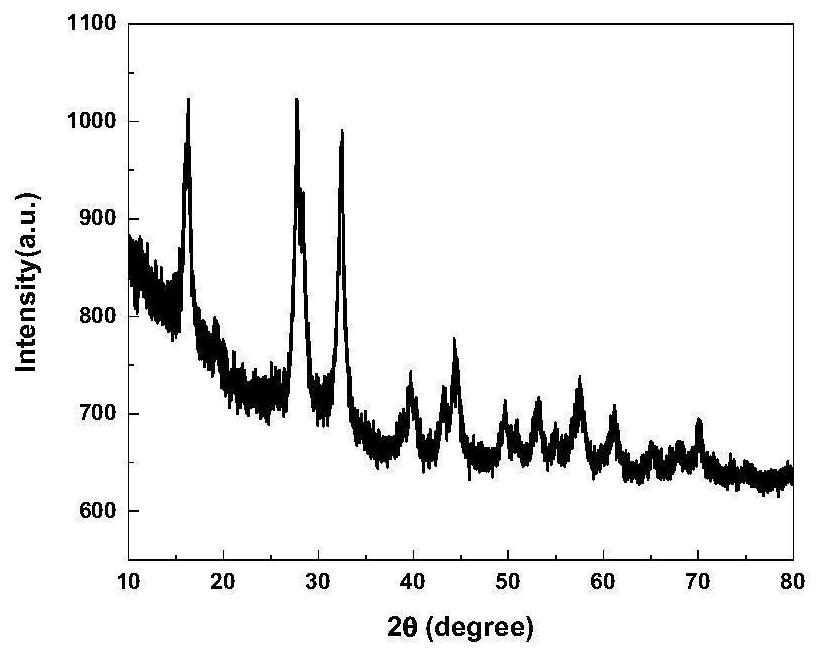

[0028]Na used in step 1)3V2(PO4)2F3It is synthesized by hydrothermal method, sol-gel method or solid phase method.

[0029]The binder in step 1) is PVDF or CMC, and the solvent is NMP or H2O.

[0030]The sample processed by atomic layer deposition in step 1) is flake rat...

Embodiment 1

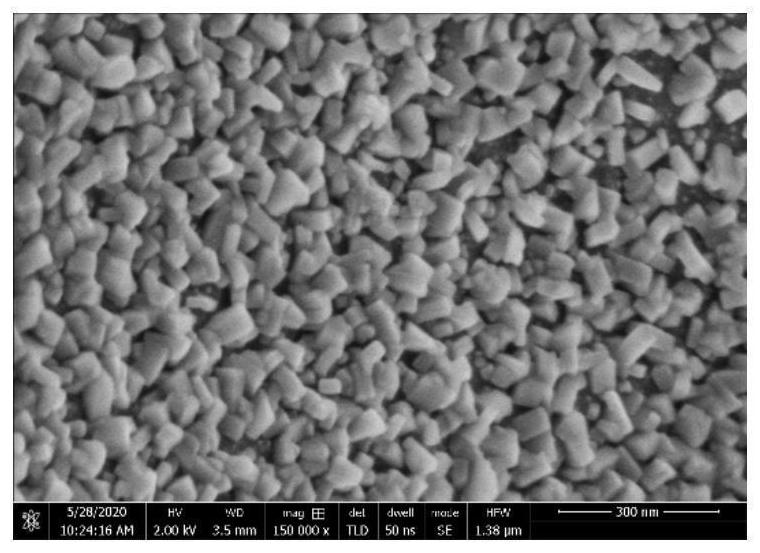

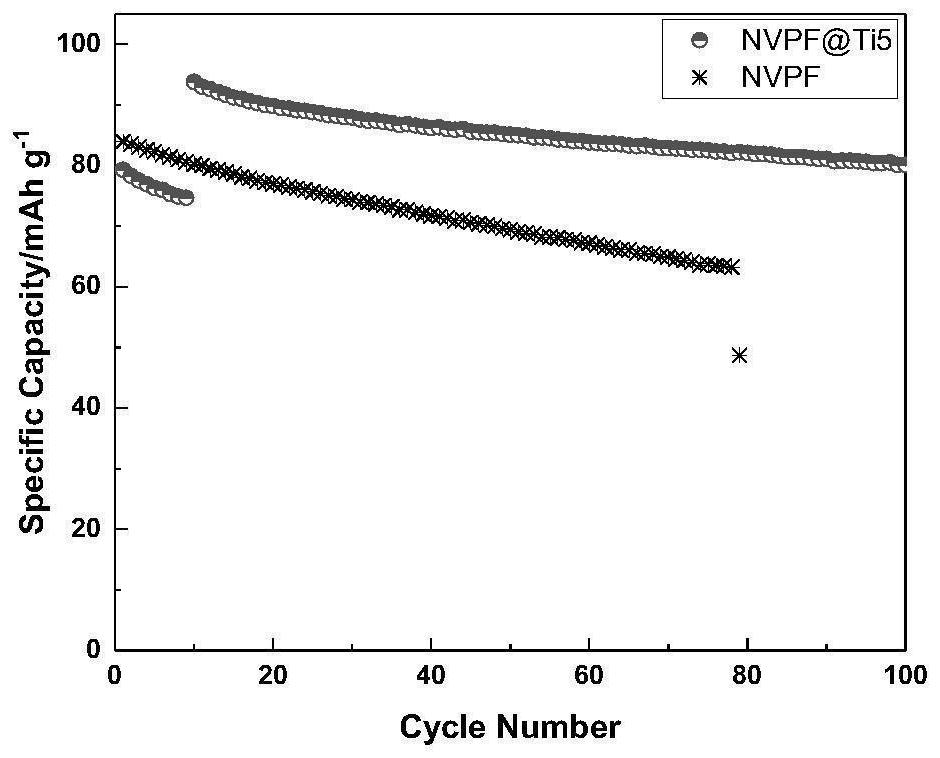

[0036]Preparation of Na by sol-gel reaction3V2(PO4)2F3Material, the binder prepared by the electrode sheet is PVDF, the solvent is NMP; the temperature of the reaction chamber of the atomic layer deposition system is 150℃, the pressure is 40Pa, the metal precursor is titanium tetraisopropoxide, the temperature of the source bottle is set to 60℃, and the number of cycles is 20cycle , Deposited TiO2Molecular layer.

[0037]1) Preparation of Na by sol-gel reaction3V2(PO4)2F3material

[0038]Weigh a certain mass of NaF, NH according to Na:V:P:F=3:2:2:34VO3And NH4H2PO4, Dissolve the three drugs in 30ml ultrapure water, and add a certain amount of citric acid monohydrate as a chelating agent to the NaF aqueous solution. A magnetic stir bar was added to the three solutions to stir to obtain a uniformly mixed aqueous solution.

[0039]The above three solutions are mixed. The mixed solution is placed on a magnetic heating stirring table for oil bath heating, and the oil bath heating temperature is se...

Embodiment 2

[0047]Prepare Na according to the example3V2(PO4)2F3Materials, and proceed as follows:

[0048]1) The specific steps of the electrode sheet preparation process are:

[0049]First weigh 20 mg of binder PVDF, pour it into a ball mill tank, and add organic NMP solvent to ball mill for 20 minutes to make the binder evenly dispersed in the solvent. Then follow the active substance Na3V2(PO4)2F3: Conductive carbon black: Binder=7:2:1 ratio of weighing medicine Na3V2(PO4)2F3: Conductive carbon black, add it to the ball milling tank and continue ball milling for about 3 hours. Use a 250μm doctor blade to scrape the ball-milled slurry on the aluminum foil, dry it at 80°C for 2h after scraping, and vacuum-dry it at 120°C for 10h to obtain a spare electrode sheet.

[0050]The process of putting the electrode sheet into the reaction chamber of the atomic layer deposition system specifically includes the following steps:

[0051]Cut the spare electrode sheet into a rectangle matching the sample stage, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com