Boric acid ester cross-linked self-repairing polymer electrolyte and preparation method and application thereof

A self-healing, polymer technology, used in circuits, electrical components, secondary batteries, etc., can solve the problems of low electrochemical performance and poor stability of solid electrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

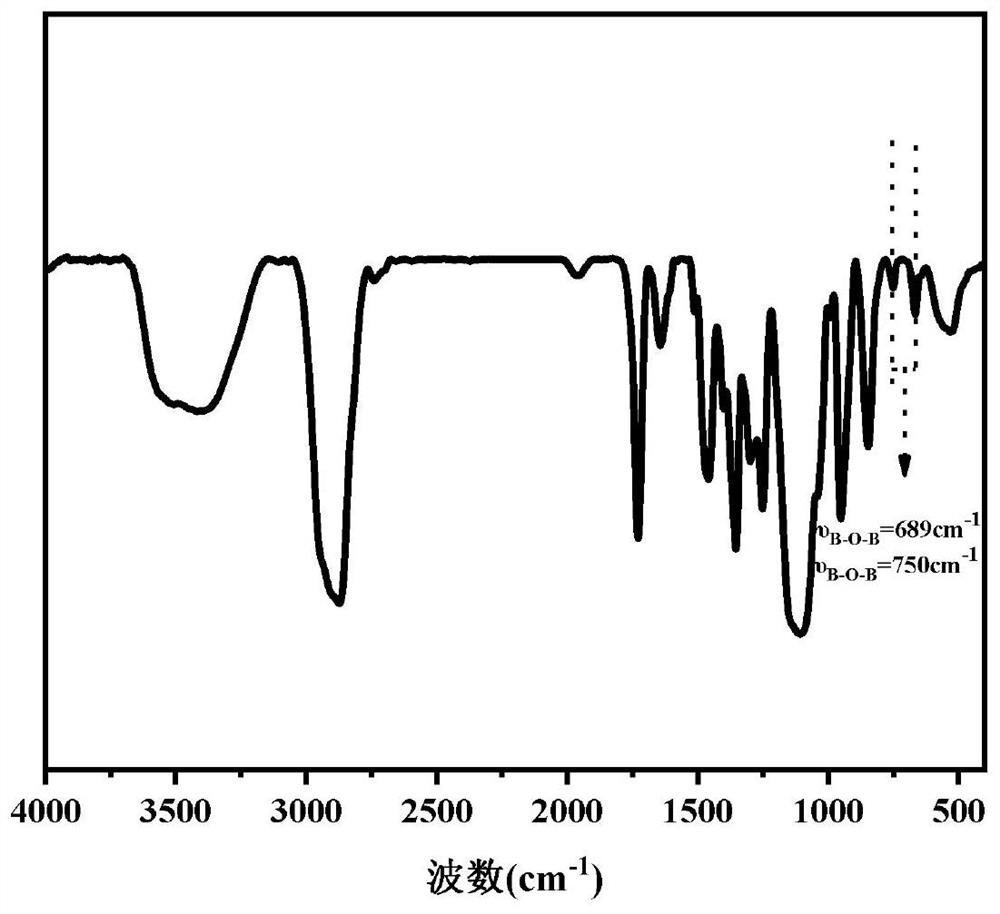

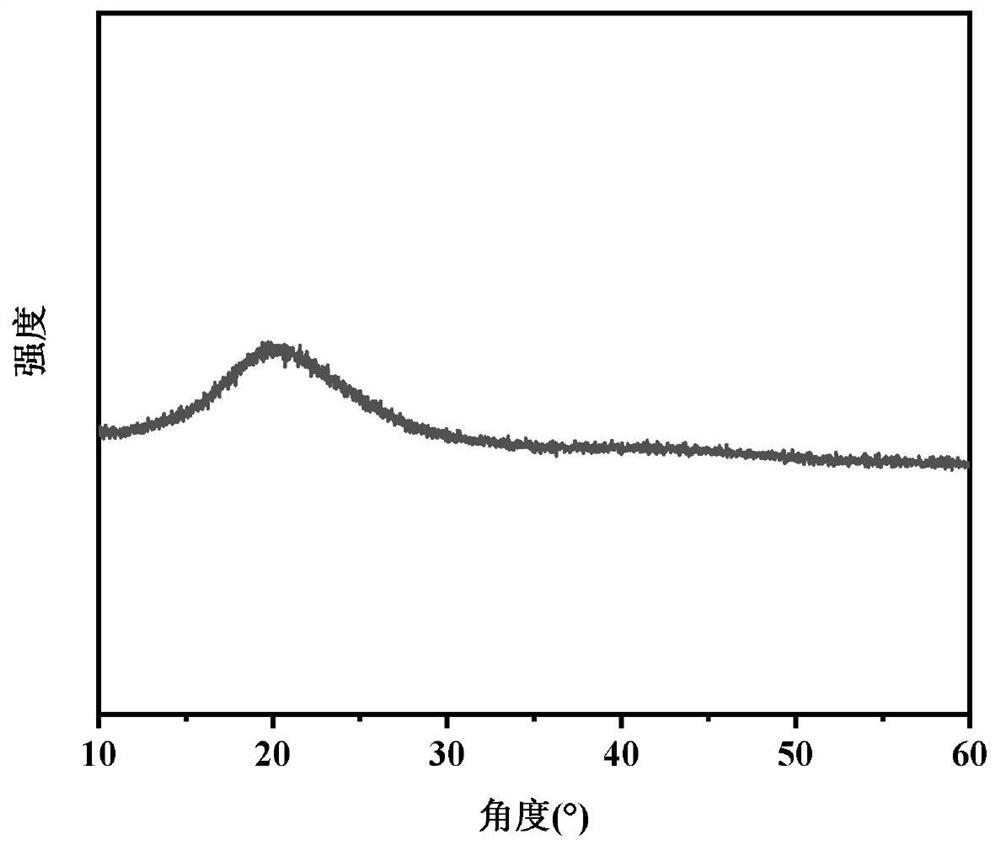

[0029] The invention provides a preparation method of a borate cross-linked self-repairing polymer electrolyte, comprising the following steps:

[0030] (1) mixing polyethylene glycol methyl ether methacrylate, 2,3-dihydroxypropyl methacrylate, a boric acid-containing crosslinking agent, a lithium salt, a photoinitiator and an organic solvent to obtain a mixed solution;

[0031] (2) Casting the mixed solution obtained in the step (1) into a mold, and then performing light curing to obtain a borate cross-linked self-healing polymer electrolyte.

[0032] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in the field.

[0033] In the present invention, polyethylene glycol methyl ether methacrylate, 2,3-dihydroxypropyl methacrylate, a boric acid-containing crosslinking agent, a lithium salt, a photoinitiator and an organic solvent are mixed to obtain a mixed solution.

[0034] The source of 2,3-dihydroxyp...

Embodiment 1

[0058] One, the preparation method of 2,3-dihydroxypropyl methacrylate

[0059] 50mmol of glycidyl methacrylate GMA and 80mL of ultrapure water were added to a 250mL flask, mixed and stirred for 1 hour, the solution became turbid, then heated to 80 ° C and carried out hydrolysis reaction for 24 hours, the two-phase system was transformed into a colorless transparent solution (homogeneous phase). ), the product of the hydrolysis reaction was rotary evaporated at 80°C for 30min to obtain 2,3-dihydroxypropyl methacrylate (HGMA);

[0060] The volume ratio of the glycidyl methacrylate and ultrapure water is 0.08:1.

[0061] 2. Preparation method of borate cross-linked self-healing polymer electrolyte

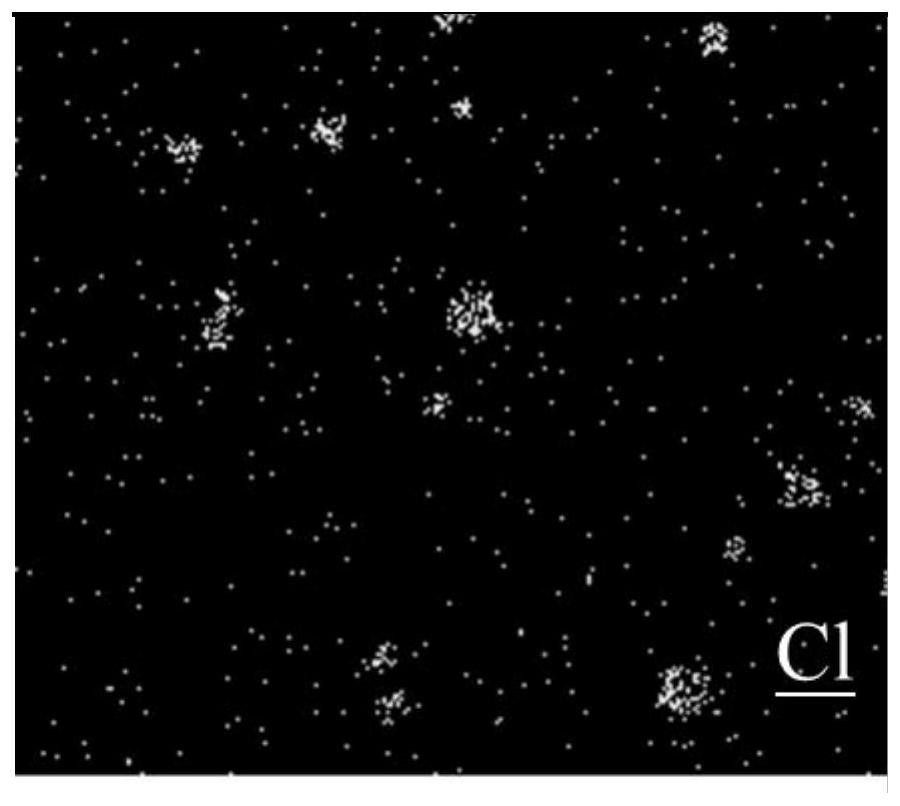

[0062] (1) Polyethylene glycol methyl ether methacrylate (1.00 g, 2 mmol), 2,3-dihydroxypropyl methacrylate (0.32 g, 2 mmol) prepared by the above method, and a cross-linking agent containing boric acid were added to Phenyldiboronic acid (0.083 g, 0.5 mmol), lithium salt lithium pe...

Embodiment 2

[0068] Prepare borate cross-linked self-healing polymer electrolyte according to the method of Example 1;

[0069] The difference from Example 1 is that in the step (1), lithium salt lithium perchlorate (0.08g, 0.76mmol) is used, and in the polyethylene glycol segment in the polyethylene glycol methyl ether methacrylate, The ratio of the amount of oxygen atoms to lithium atoms in the lithium salt (i.e. [O] / [Li + ] ratio) is 24:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com