Composite phosphate coated lithium ion battery high-nickel positive electrode material and preparation method thereof

A lithium-ion battery and composite phosphate technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as poor safety and cycle life, harsh use environment requirements, and low coulombic efficiency in the first cycle, and achieve Effects of suppressing irreversible phase transition and microcracks, low manufacturing cost, and suppressing irreversible capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

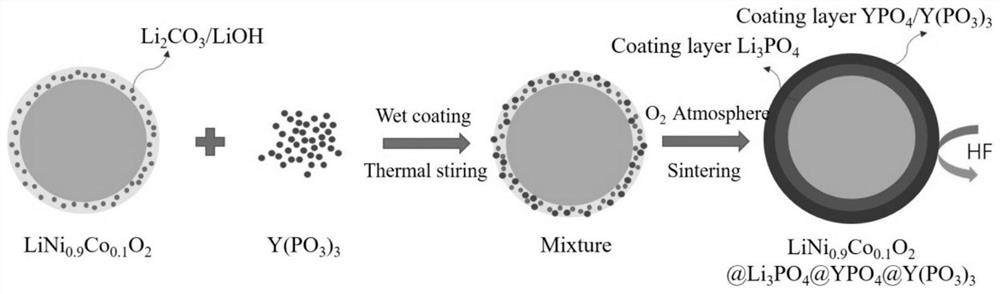

[0049] This embodiment provides a kind of composite phosphate coated lithium-ion battery high-nickel cathode material LiNi 0.9 co 0.1 o 2 , among which, the high-nickel cathode material LiNi for lithium-ion batteries 0.9 co 0.1 o 2 As the parent material, yttrium metaphosphate Y (PO 3 ) 3 For coating raw materials, Y(PO 3 ) 3 Residual alkali (LiOH, Li 2 CO 3 ) in-situ reaction to form a composite phosphate coating; the coating amount of yttrium metaphosphate is the parent cathode material LiNi 0.9 co 0.1 o 2 (Matrix material) of 2wt%.

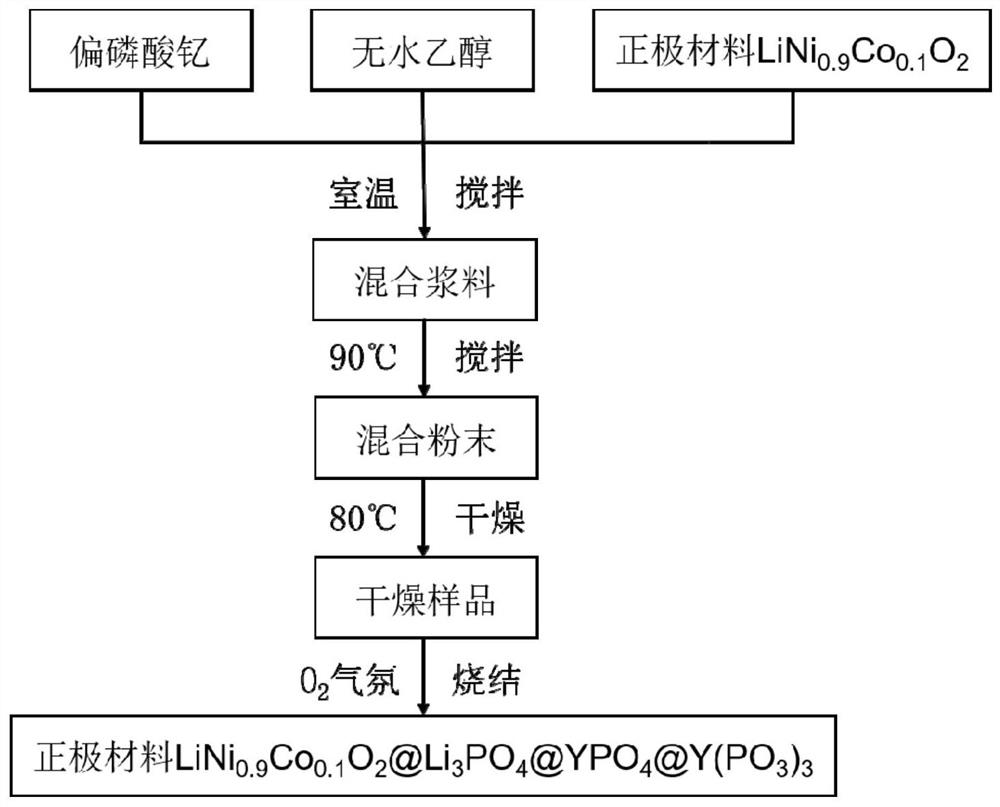

[0050] The above-mentioned composite phosphate-coated lithium-ion battery high-nickel cathode material LiNi 0.9 co 0.1 o 2 The preparation process such as figure 2 shown, including:

[0051] According to the coating amount, 0.04gY(PO 3 ) 3 Disperse in 30-40ml of absolute ethanol, and sonicate for 10-30min to form a suspension solution;

[0052] Then add 2.0g parent cathode material LiNi in the solution 0.9 co 0.1 o 2 , S...

Embodiment 2

[0060] This embodiment provides a kind of composite phosphate coated lithium-ion battery high-nickel cathode material LiNi 0.9 co 0.1 o 2 , the only difference between it and Example 1 is that the coating amount of yttrium metaphosphate is the parent cathode material LiNi 0.9 co 0.1 o 2 (Matrix material) 1 wt%; After testing, the principle and electrochemical performance of the positive electrode material provided in this embodiment are basically the same as those in Example 1.

Embodiment 3

[0062] This embodiment provides a kind of composite phosphate coated lithium-ion battery high-nickel cathode material LiNi 0.9 co 0.1 o 2 , the only difference between it and Example 1 is that the coating amount of yttrium metaphosphate is the parent cathode material LiNi 0.9 co 0.1 o 2 (Matrix material) 3wt%; After testing, the principle and electrochemical performance of the positive electrode material provided in this example are basically the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com