A one-step method for co-modifying ternary cathode materials by ion doping and surface coating

A positive electrode material and surface coating technology, which is applied in the field of ion doping and surface coating to modify ternary positive electrode materials, can solve the problems of complex modification process of ternary positive electrode materials, improve the stability of material structure and save costs , Reduce the effect of interface side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

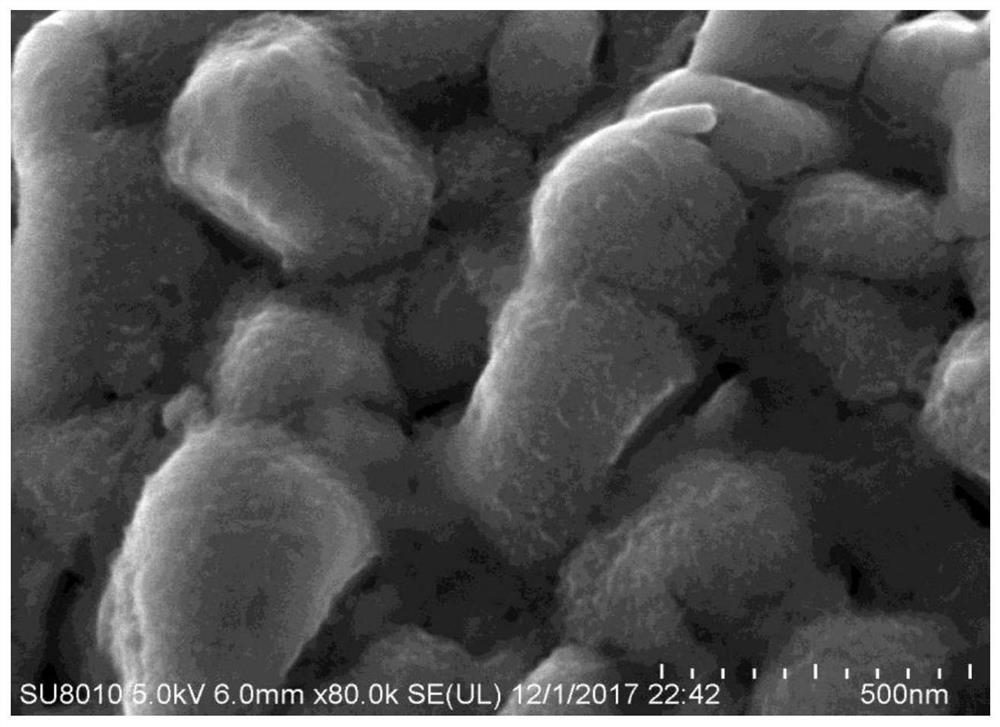

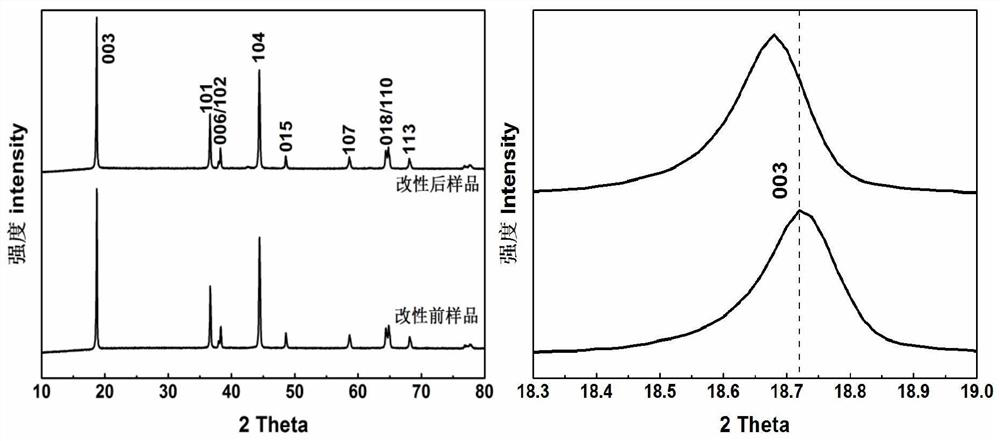

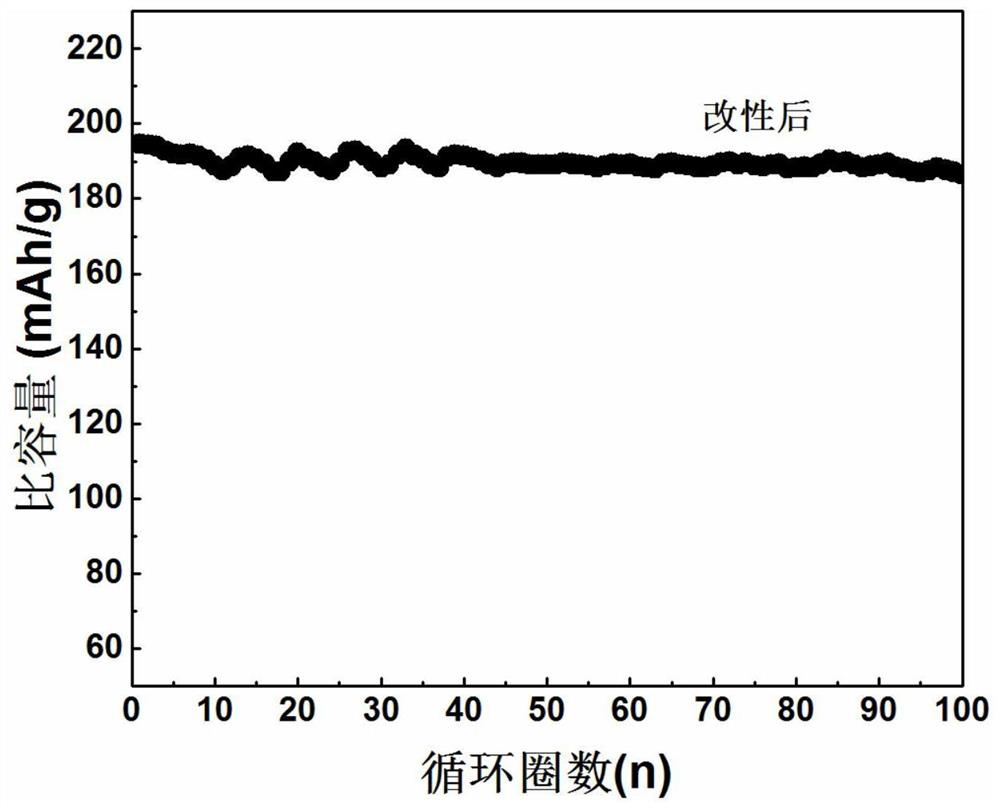

[0036] 1. Using 8-hydroxyquinoline as a complexing agent, tetrabutyl titanate as a metal ion salt solution, and LiNi 0.8 co 0.1 mn 0.1 o 2 As the substrate, prepare the surface Ti doping and TiO 2 The specific preparation method of the coated nickel-based positive electrode material is as follows:

[0037] 1. Weigh an excess of 20% 8-hydroxyquinoline at the ratio of metal ion: 8-hydroxyquinoline = 1:4 (mol), dissolve the complexing agent and ternary material in absolute ethanol solution, and ultrasonically After processing for 15 minutes, continue to stir for 2 hours to obtain a ternary positive electrode material adsorbed by a complexing agent, and the amount of the metal ion salt solution is 2%wt of the mass of the substrate;

[0038] 2. Add the metered ratio of tetrabutyl titanate (TBOT) dropwise to the above mixed solution which is being stirred, and keep stirring at room temperature for 2 hours;

[0039] 3. Transfer the above fully mixed solution to an 80°C oil bath,...

Embodiment 2

[0045] 1. Using 8-hydroxyquinoline as complexing agent, aluminum isopropoxide as metal ion salt solution, and LiNi 0.8 co 0.1 mn 0.1 o 2 As the matrix, prepare the surface layer Al doping and Al 3 o 2 The specific preparation method of the coated nickel-based positive electrode material is as follows:

[0046] 1. Weigh an excess of 20% 8-hydroxyquinoline at the ratio of metal ion: 8-hydroxyquinoline = 1:3 (mol), dissolve the complexing agent and ternary material in absolute ethanol solution, and ultrasonically After 15 minutes of treatment, continue stirring for 2 hours to obtain a ternary positive electrode material adsorbed by a complexing agent, the amount of the metal ion salt solution being 1.5%wt of the mass of the substrate;

[0047] 2. Add the metered ratio of aluminum isopropoxide dropwise to the stirring above mixed solution, and keep stirring at room temperature for 2 hours;

[0048] 3. Transfer the above fully mixed solution to an 80°C oil bath, and continue ...

Embodiment 3

[0053] 1. Use 8-hydroxyquinoline as complexing agent and magnesium chloride as Mg 2+ Ionic salt solution, with LiNi 0.8 co 0.1 mn 0.1 o 2 As a substrate, prepare a surface layer Mg-doped and MgO-coated nickel-based positive electrode material. The specific preparation method is as follows:

[0054] 1. Weigh an excess of 20% 8-hydroxyquinoline at the ratio of metal ion: 8-hydroxyquinoline = 1:2 (mol), dissolve the complexing agent and ternary material in absolute ethanol solution, and ultrasonically After processing for 15 minutes, continue stirring for 2 hours to obtain a ternary positive electrode material adsorbed by a complexing agent, and the amount of the metal ion salt solution is 1%wt of the mass of the substrate;

[0055] 2. Add the metered ratio of aluminum isopropoxide dropwise to the stirring above mixed solution, and keep stirring at room temperature for 2 hours;

[0056] 3. Transfer the above fully mixed solution to an 80°C oil bath, and continue stirring unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com