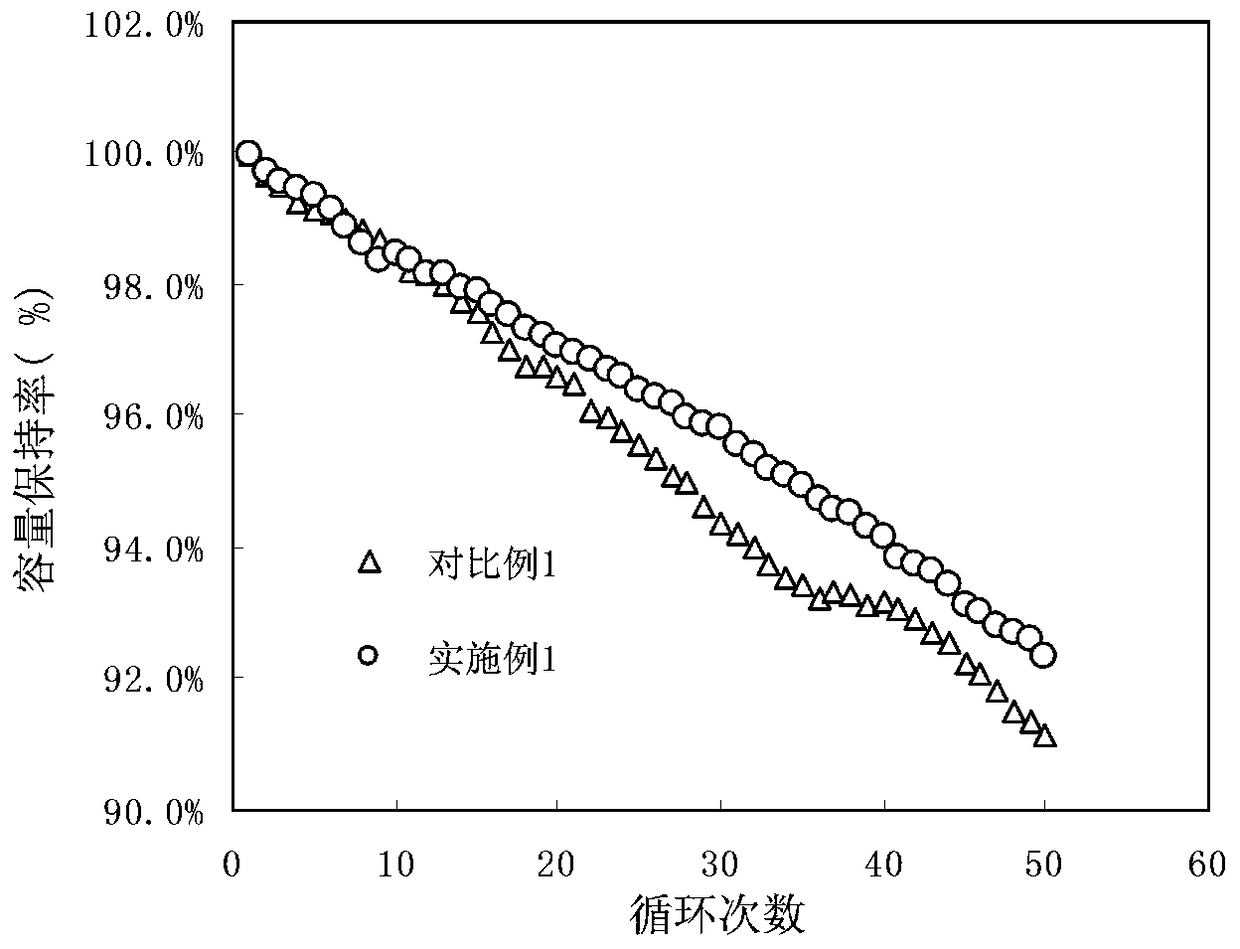

A kind of positive electrode of lithium ion battery coated with gel polymer and preparation method thereof

A lithium-ion battery, polymer technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of uneven coating, unfavorable transmission, failure to achieve ideal coating effects, etc., to achieve simple coating process, slow down Effects of interfacial side reactions, excellent cycling performance, and thermodynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a lithium ion battery positive electrode coated with a gel polymer of the present invention, comprising the steps of:

[0032] Step 1: Weigh 9.4g Li(Ni 0.5 co 0.2 mn 0.3 )O 2 After the positive electrode active material, 0.3g conductive agent, and 0.3g binder polyvinylidene fluoride (PVDF) are mixed evenly, they are added to the organic solvent N-methylpyrrolidone (NMP) and stirred repeatedly until uniform to obtain the positive electrode slurry; The positive electrode slurry is coated on a 20 μm thick current collector aluminum foil, and placed in a vacuum drying oven at 120°C for 10 hours to obtain the positive electrode sheet;

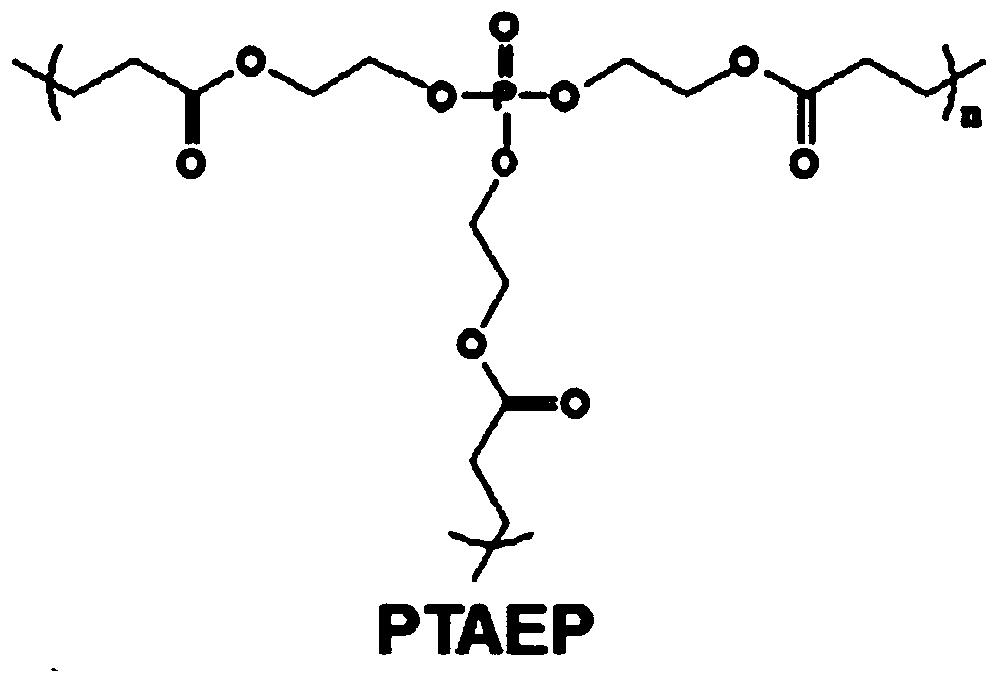

[0033] Step 2: Add 1.0g of tris(2-acryloyloxyethyl)phosphate (TAEP) to 200g of acetone solution, followed by adding 1.0mg of 2-methyl-2-hydroxy-1-phenylacetone (HMPP) The initiator is uniformly mixed to obtain a tris (2-acryloyloxyethyl) phosphate (TAEP) solution with a concentration of 0.5 wt %;

[0034] Step 3: ...

Embodiment 2

[0037] A preparation method of a lithium ion battery positive electrode coated with a gel polymer of the present invention, comprising the steps of:

[0038] Step 1: Weigh 9.6g LiCoO 2 After the positive electrode active material, 0.2g conductive agent, and 0.2g binder polyvinylidene fluoride (PVDF) are mixed evenly, they are added to the organic solvent N-methylpyrrolidone (NMP) and stirred repeatedly until uniform to obtain the positive electrode slurry; The positive electrode slurry is coated on a 20 μm thick current collector aluminum foil, and placed in a vacuum drying oven at 110 ° C for 12 hours to obtain the positive electrode sheet;

[0039] Step 2: Add 1.6g of tris(2-acryloyloxyethyl)phosphate (TAEP) to 200g of acetone solution, followed by 1.3mg of 2-methyl-2-hydroxy-1-phenylacetone (HMPP) Initiator, mixed evenly to obtain a TAEP solution with a concentration of 0.8wt%;

[0040] Step 3: Place the positive pole piece prepared in step 1 in the 0.8wt% tris(2-acryloyl...

Embodiment 3

[0043] A preparation method of a lithium ion battery positive electrode coated with a gel polymer of the present invention, comprising the steps of:

[0044] Step 1: Weigh 9.5g Li 1.2 (Mn 0.56 Ni 0.16 co 0.08 )O 2 (The expression can also be written as 0.6Li[Li 1 / 3 mn 2 / 3 ]O 2 0.4Li[Ni 0.4 mn 0.4 co 0.2 ]O 2 ) after the positive electrode active material, 0.3g conductive agent, and 0.2g binder polyvinylidene fluoride (PVDF) are mixed evenly, after adding in the organic solvent N-methylpyrrolidone (NMP), stir repeatedly until uniform, and obtain the positive electrode slurry; then Coat the positive electrode slurry on a current collector aluminum foil with a thickness of 20 μm, place it in a vacuum oven and dry it at 100°C for 12 hours to obtain the positive electrode sheet;

[0045] Step 2: Prepare tris(2-acryloyloxyethyl) phosphate (TAEP) solution: first add 2.0g tris(2-acryloyloxyethyl)phosphate (TAEP) to 200g acetone solution, then add 2.4 mg 2-methyl-2-hydroxyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| UV radiation | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com