Colloidal electrolyte for starting type battery

A colloidal electrolyte and start-up technology, applied in lead-acid batteries, etc., can solve problems such as loss, prolong service life, avoid water loss, and solve powder removal and deposition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

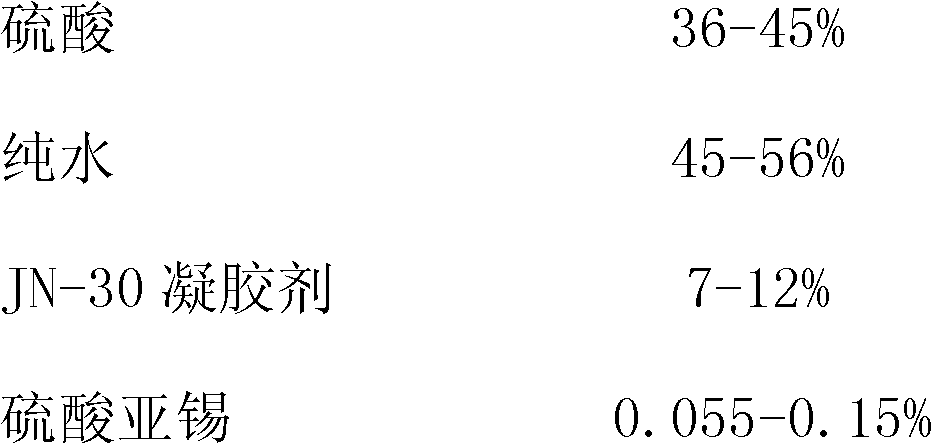

[0017] The colloidal electrolyte for starter batteries consists of the following components and the mass percentage of each component is:

[0018]

[0019]

[0020] Sulfuric acid is reagent sulfuric acid, which is the main active material of lead-acid battery; pure water is sulfuric acid diluent and auxiliary agent, conductivity: ≤2μS / cm; JN-30 gel is electrolyte gel; stannous sulfate is analysis Pure grade, the function is to improve conductivity and over-discharge recovery ability; Al2O3 solid super acid, improve overcharge resistance and increase the number of cycles; sodium carboxymethyl cellulose is used as a thickener and colloid stabilizer; zinc sulfate Increase the solubility of lead sulfate and improve the charging acceptance; the function of bismuth trioxide is to improve the utilization rate of active materials, inhibit the precipitation of hydrogen, improve the oxygen reduction ability, and improve the cycle life of batteries; phosphoric acid is analytically p...

Embodiment 2

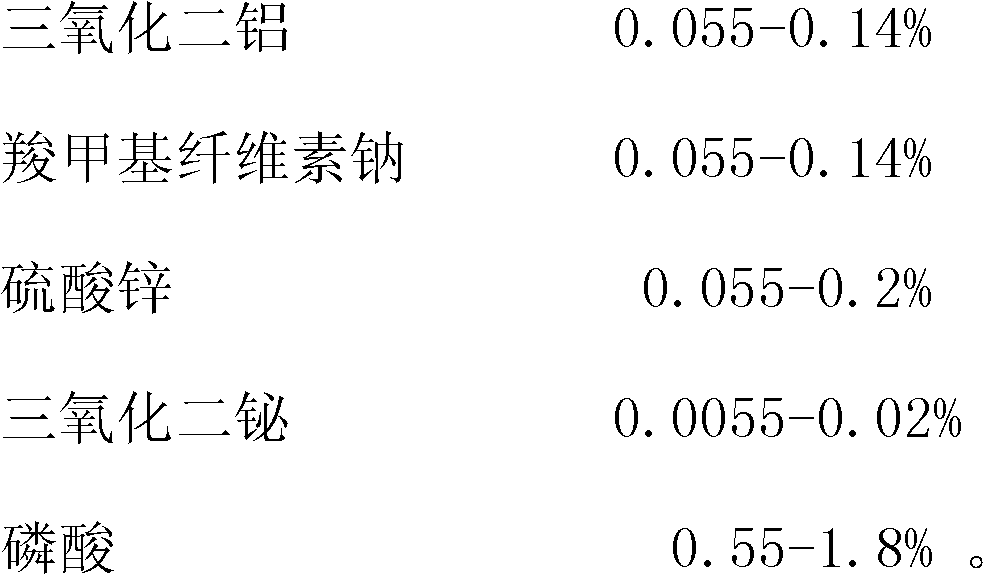

[0042] The colloidal electrolyte for starter batteries consists of the following components and the mass percentage of each component is:

[0043]

Embodiment 3

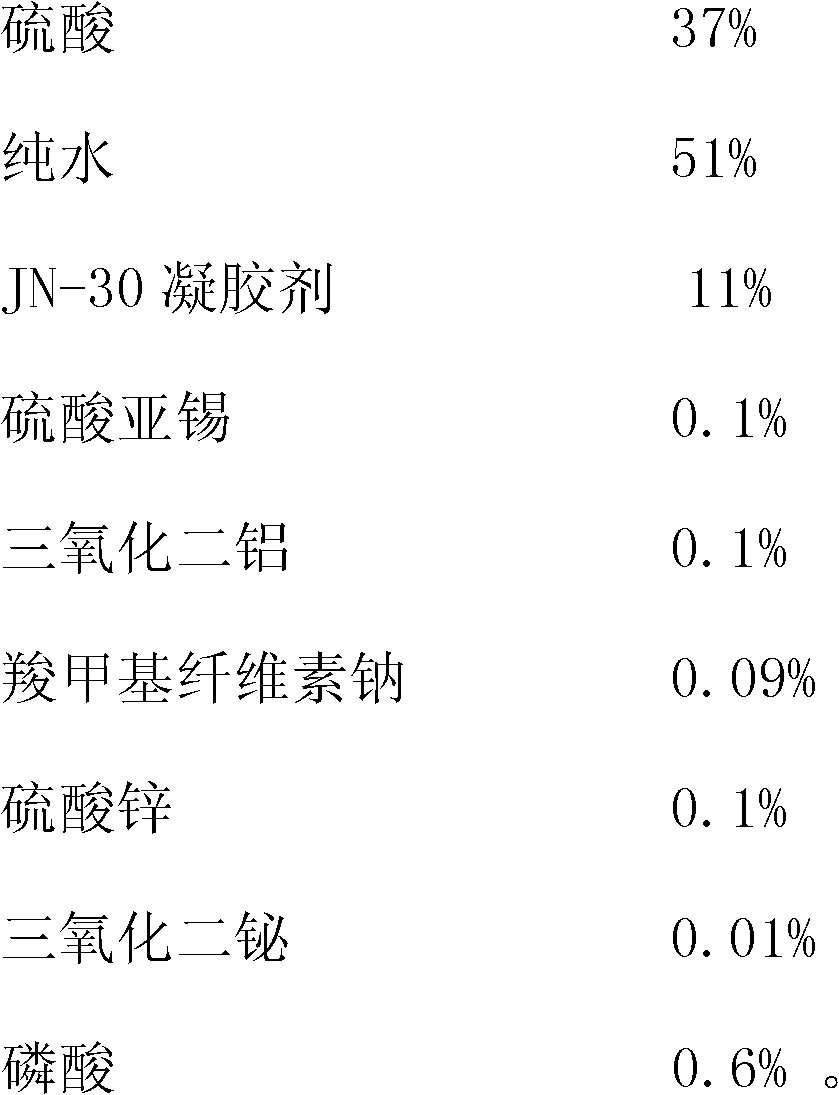

[0045] The colloidal electrolyte for starter batteries consists of the following components and the mass percentage of each component is:

[0046]

[0047] The colloidal electrolyte in the above ratio is used for maintenance-free starter batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com