Laser metal additive deposition temperature control method and system

A metal additive and deposition temperature technology, applied in additive processing, laser welding equipment, metal processing equipment, etc., can solve the problems of low accuracy, complex system, inability to quantitatively control the temperature of the molten pool, etc., to improve the control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

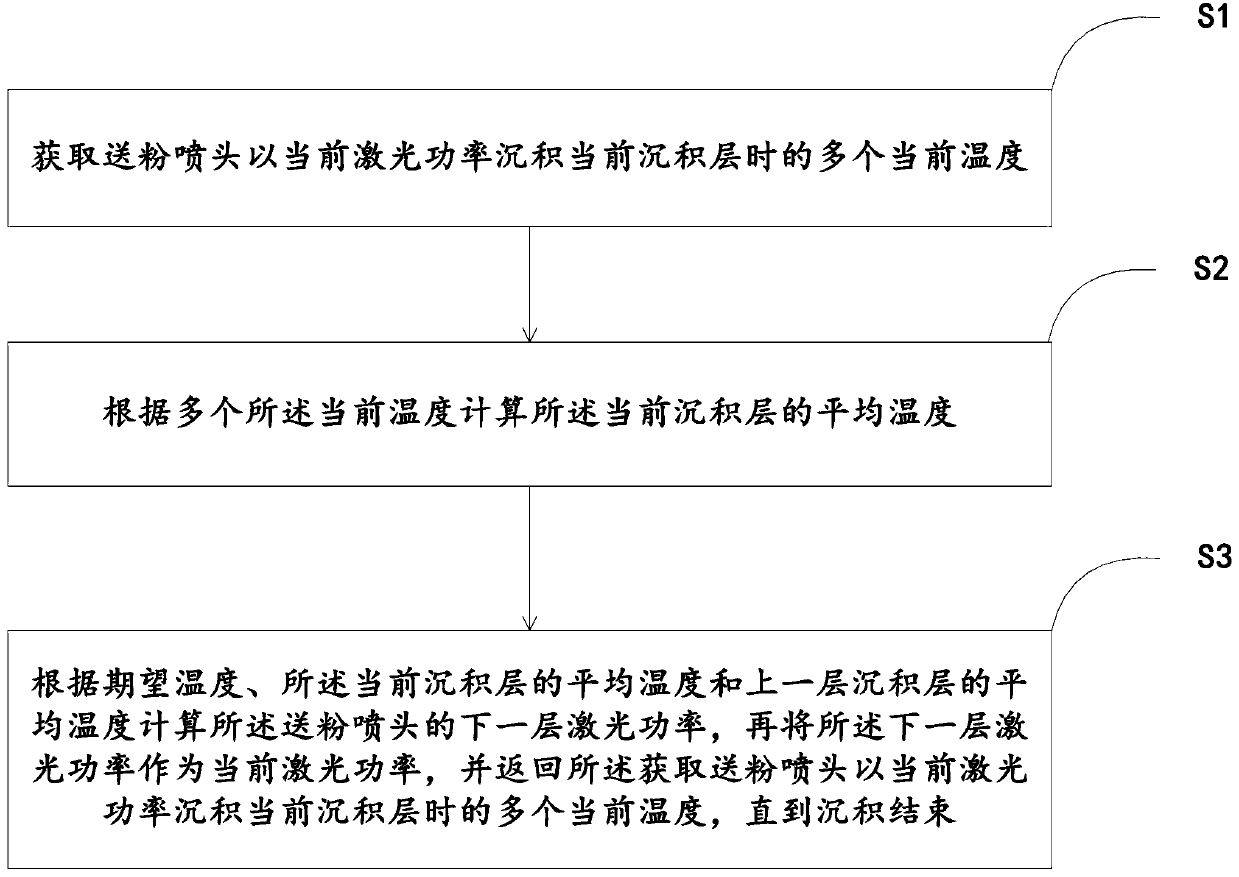

[0043] Such as figure 1 As shown, a method for controlling the temperature of laser metal additive deposition, comprising:

[0044] S1: Obtain multiple current temperatures when the powder feeding nozzle deposits the current deposition layer with the current laser power.

[0045] The multiple current temperatures are obtained by collecting the temperature of the deposits ejected from the powder feeding nozzle within a set range during the process of forming the current deposition layer.

[0046] S2: Calculate the average temperature of the current deposition layer according to the plurality of current temperatures.

[0047] The method for determining the current temperature described in S1 is:

[0048] In the process of forming the current deposition layer 8, the schematic diagram of the temperature collection points in this embodiment, as Figure 4 As shown, a thermometer is used to collect the temperature of the deposits ejected from the powder feeding nozzle within the s...

Embodiment 2

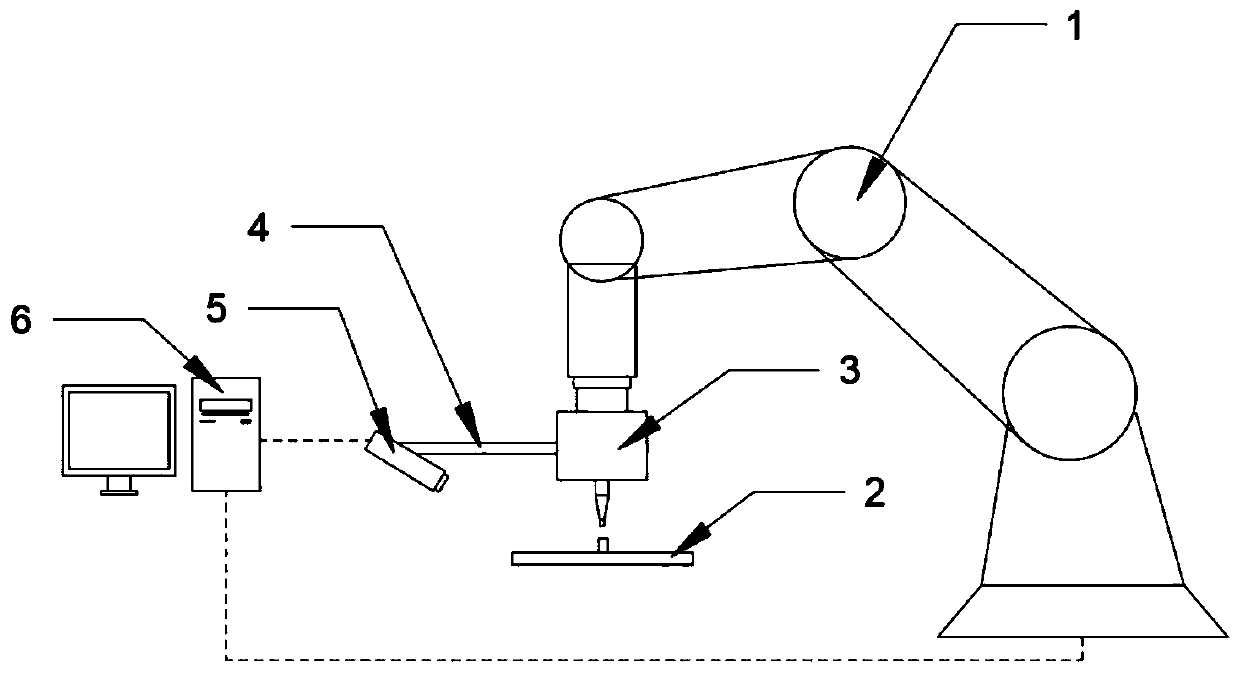

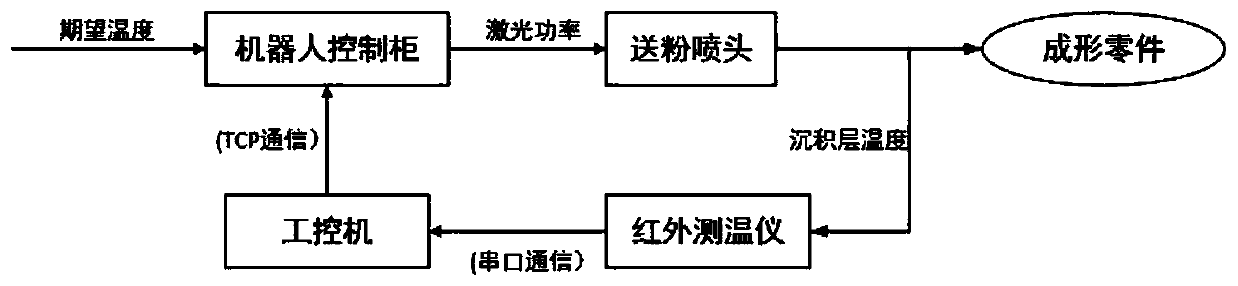

[0058] Such as figure 2 As shown, the laser metal additive deposition temperature control system includes: a powder feeding nozzle 3, a substrate 2, a temperature measuring instrument and a controller; the powder feeding nozzle 3 is arranged directly above the substrate 2, and the control Device is connected with described powder feeding nozzle 3 and described thermometer respectively; Described thermometer can be infrared thermometer 5, and described controller can be Kuka robot 1 (KUKA robot), and described thermometer In the process of forming the current deposition layer, temperature acquisition is performed on the deposits ejected from the powder feeding nozzle 3 within a set range to obtain a plurality of current temperatures, and the controller is used to obtain a plurality of the current temperature and calculate the average temperature of the current deposition layer according to a plurality of the current temperatures, and then control the powder feeding nozzle 3 ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com