Method for preparing high-purity montmorillonite

A montmorillonite, high-purity technology, applied in chemical instruments and methods, aluminum silicate, silicate, etc., can solve the problems of water and energy consumption, cumbersome sodium treatment, etc., to enhance suspension performance, improve purity and Good yield, dispersibility and suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

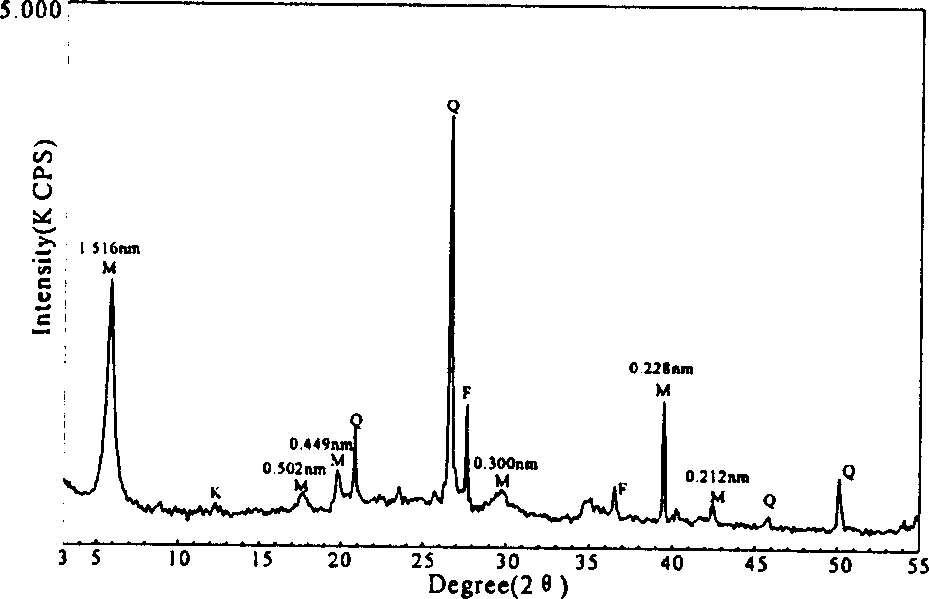

[0041] ① Raw materials: Zhejiang Anji light green calcium-based bentonite ( figure 1 ), mainly composed of montmorillonite (M), quartz (Q), feldspar (F) and kaolinite (K), of which montmorillonite accounts for about 66%, kaolinite accounts for about 6%, and quartz accounts for about 21%, feldspar about 7%. The moisture content is about 10%. The raw ore is crushed to 325 mesh, and the whiteness is 71%.

[0042] ②Put 100 kg of the above-mentioned Anji bentonite powder, 5 kg of urea powder and 4 kg of sodium carbonate powder into a high-speed mixer, and mix at 1000r / min at 80°C for 30 minutes to obtain a hyperdispersible bentonite with an expansion rate of 50ml / g .

[0043] ③ Add super-dispersible bentonite to 900 kg of water and stir to make slurry.

[0044] ④ The bentonite slurry is centrifugally classified by a centrifuge to obtain a high-purity montmorillonite slurry.

[0045] ⑤ Add sulfuric acid to the high-purity montmorillonite slurry to adjust the pH value to 2-4, th...

Embodiment 2

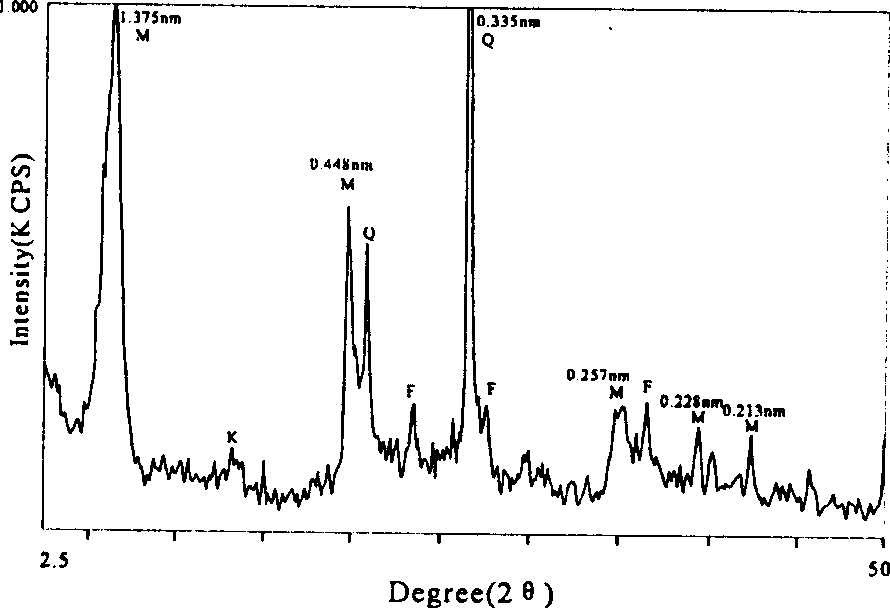

[0048] ① Raw materials: choose gray-white sodium-based bentonite raw ore from Anji, Zhejiang ( image 3 ), mainly composed of montmorillonite (M), quartz (Q), feldspar (F) and kaolinite (K), of which montmorillonite accounts for about 77%, kaolinite accounts for about 5%, and quartz accounts for about 15%, and feldspar accounts for about 3%. The moisture content is about 10%. The raw ore is crushed to 325 mesh with a whiteness of 79%.

[0049] ② Mix 100 kg of bentonite powder, 5 kg of urea powder and 4 kg of sodium carbonate powder evenly, place in an oven, and bake at 70°C for 180 minutes to obtain a hyperdispersible bentonite with an expansion ratio of 95ml / g.

[0050] ③The super-dispersible bentonite is mixed with water according to the soil-water ratio of 800 kg to make slurry.

[0051] ④ The bentonite slurry is centrifugally classified by a centrifuge to obtain a high-purity montmorillonite slurry.

[0052] ⑤ Add sulfuric acid to the high-purity slurry to adjust the P...

Embodiment 3

[0055] ① Crush the bentonite to 325 mesh.

[0056] ②Put 100 kg of bentonite powder, 3 kg of urea powder and 10 kg of sodium fluoride powder in an oven, and bake at 130°C for 180 minutes to obtain a hyperdispersible bentonite with an expansion ratio of 60ml / g.

[0057] Other steps are with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com