SnS2/g-C3N4 composite nanosheet photocatalyst and preparation method thereof

A photocatalyst, g-c3n4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of easy manipulation, simple preparation method, and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

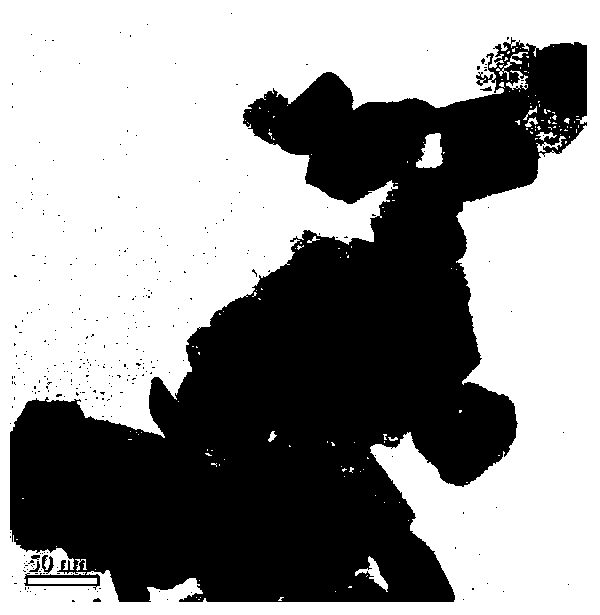

[0026] Dissolve 0.125mmol tin tetrachloride pentahydrate and 1mmol thioacetamide in 20ml aqueous solution, and stir for 30 minutes. The dissolved solution was placed in a 25ml reaction kettle, and then the sealed reaction kettle was placed in an electric oven for hydrothermal reaction. The hydrothermal temperature was 160° C. for 12 hours. After the reaction, the reaction kettle was naturally cooled to room temperature, opened, and the obtained product was taken out and centrifuged to obtain a yellow precipitate, which was washed with deionized water and ethanol respectively, and then the product was vacuum-dried at 60°C for 8 hours to obtain SnS 2 nanosheet material. SnS 2 Transmission electron microscope images of the nanosheets as figure 1 shown. It can be clearly seen from the figure that the prepared SnS 2 The size of the nano sheet is 40-80nm, and the thickness is 8-15nm.

[0027]Weigh 10g of urea powder, grind and mix it evenly, put it into an alumina crucible, cov...

example 2

[0030] Dissolve 0.125mmol tin tetrachloride pentahydrate and 2mmol thioacetamide in 20ml aqueous solution, and stir for 30 minutes. The dissolved solution was placed in a 25ml reaction kettle, and then the sealed reaction kettle was placed in an electric oven for hydrothermal reaction. The hydrothermal temperature was 170° C. for 10 hours. After the reaction, the reaction kettle was naturally cooled to room temperature, opened, and the obtained product was taken out and centrifuged to obtain a yellow precipitate, which was washed with deionized water and ethanol respectively, and then the product was vacuum-dried at 60°C for 12 hours to obtain SnS2 nanometer sheet material.

[0031] Weigh 10g of urea powder, grind and mix it evenly, put it into an alumina crucible, cover it and put it into a muffle furnace, raise it to 580°C at a rate of 30°C / min in an air atmosphere, and keep it for 2.5 hours. After naturally cooling to room temperature, take it out and grind it finely to ob...

example 3

[0034] Dissolve 0.125mmol tin tetrachloride pentahydrate and 0.625mmol thioacetamide in 20ml aqueous solution, and stir for 30 minutes. The dissolved solution was placed in a 25ml reaction kettle, and then the sealed reaction kettle was placed in an electric oven for hydrothermal reaction. The hydrothermal temperature was 180° C. for 16 hours. After the reaction, the reaction kettle was naturally cooled to room temperature, opened, and the obtained product was taken out and centrifuged to obtain a yellow precipitate, which was washed with deionized water and ethanol respectively, and then the product was vacuum-dried at 60°C for 9 hours to obtain SnS 2 nanosheet material.

[0035] Weigh 10g of urea powder, grind and mix it evenly, put it into an alumina crucible, cover it and put it into a muffle furnace, raise it to 500°C at a rate of 15°C / min under a nitrogen atmosphere, and keep it for 3 hours. After naturally cooling to room temperature, take it out and grind it finely to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com