Photocatalyst and preparing method thereof

A technology of photocatalyst and nano-titanium dioxide, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., and can solve problems such as limiting the application environment and application range of photocatalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

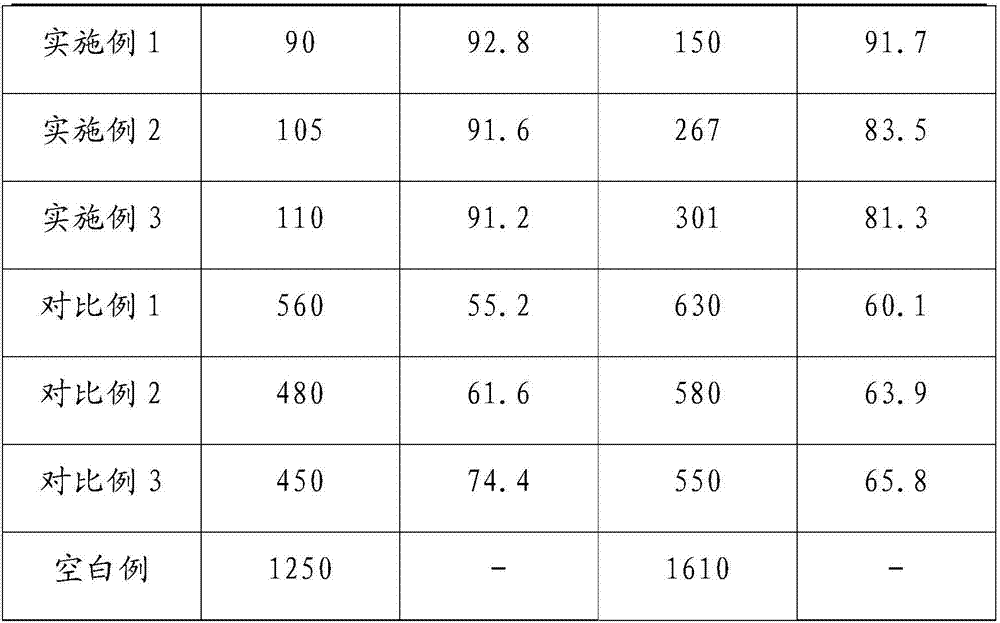

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing the photocatalyst, comprising:

[0033] Steps for preparing titanium dioxide sol: add tetrabutyl titanate solution into absolute ethanol, prepare tetrabutyl titanate ethanol solution with a weight percentage of 12-18%, and prepare deionized water and Ethanol mixed solution, drop the same volume of deionized water and ethanol mixed solution into the tetrabutyl titanate ethanol solution, stir while dropping, keep the solution temperature at 28-30°C, wait until the deionized water and ethanol mixed solution is completely After dripping the tetrabutyl titanate ethanol solution, continue stirring for 2-3 hours to obtain a uniform and transparent titanium dioxide sol;

[0034] Steps for preparing silica sol: add ethyl orthosilicate to absolute ethanol, prepare ethyl orthosilicate ethanol solution with a weight percentage of 10-15%, and prepare deionized water at a ratio of 1:2 by volume Mixed solution with ethanol, d...

Embodiment 1-5

[0046] Embodiment 1-5 photocatalyst

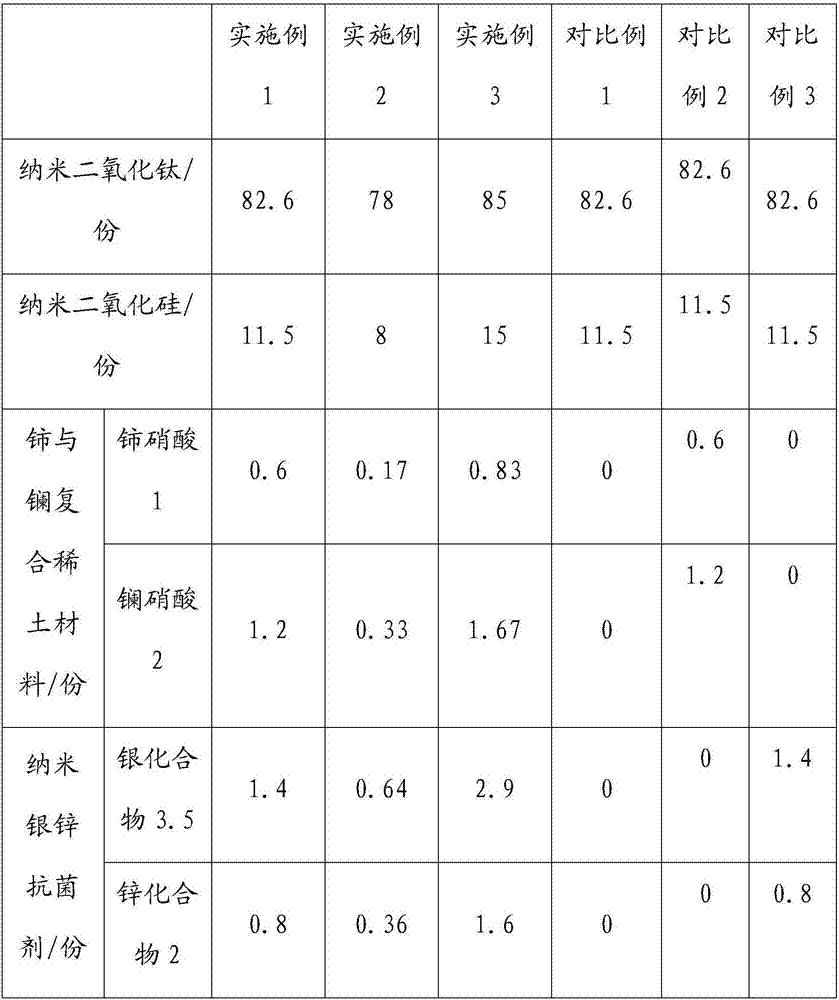

[0047] The raw materials are weighed according to the ratio in Table 1 respectively, and the photocatalyst is prepared according to the following steps, the difference is that the added raw material ratio is different, see Table 1 for details:

[0048] Table 1 The raw material proportion table of embodiment 1-3 and comparative example 1-3

[0049]

[0050] The preparation method of photocatalyst is as follows, comprising,

[0051] Steps for preparing titanium dioxide sol: add tetrabutyl titanate solution into absolute ethanol, prepare tetrabutyl titanate ethanol solution with a weight percentage of 12-18%, and prepare deionized water and Ethanol mixed solution, drop the same volume of deionized water and ethanol mixed solution into the tetrabutyl titanate ethanol solution, stir while dropping, keep the solution temperature at 28-30°C, wait until the deionized water and ethanol mixed solution is completely After dripping the tetrabutyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com