Chitosan spraying film agent and preparation method thereof

A technology of spray film and chitosan, which is applied in the field of medicine, can solve the problems of complex preparation process, influence on drug safety, strong irritation, etc., and achieve the goal of treating skin wound infection, good clinical application prospect and high bioavailability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

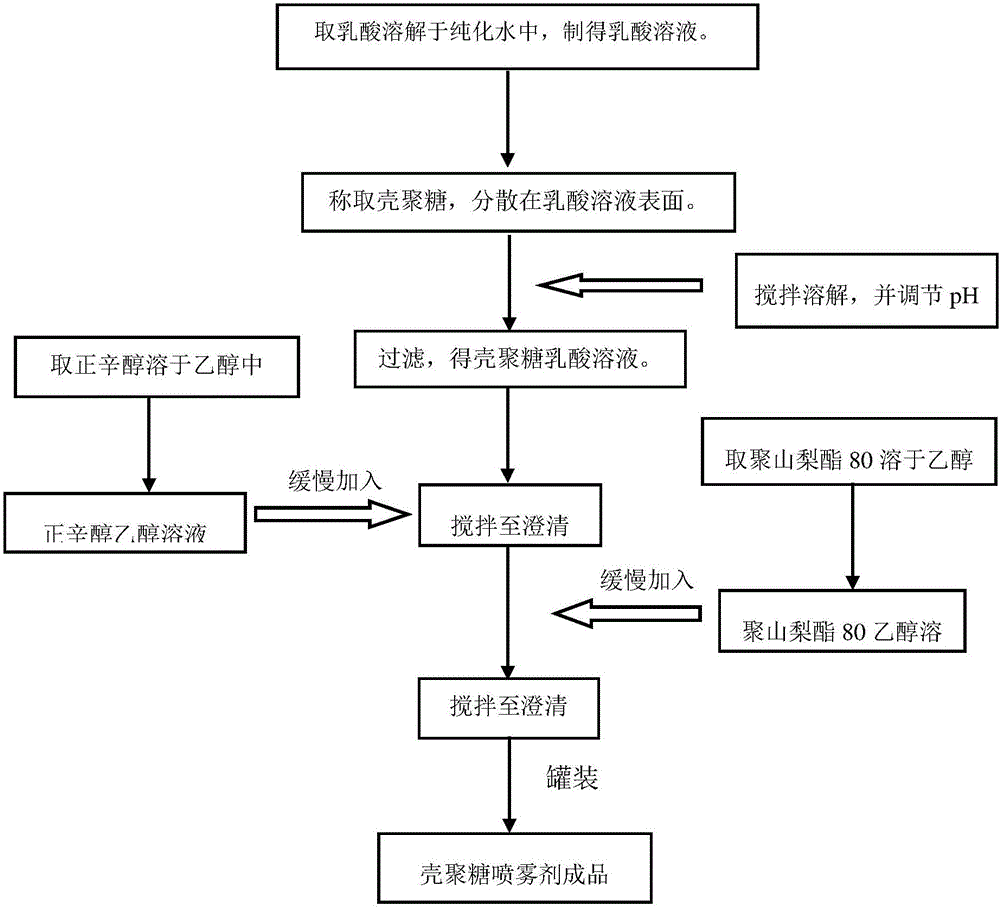

[0036] The preparation technology of embodiment 1 chitosan spray film agent

[0037] Dissolve 0.05g of lactic acid in 100g of purified water to make a 0.05% lactic acid solution; weigh 0.2g of chitosan (molecular weight: 30w), disperse it on the surface of the 0.05% lactic acid solution and swell for 30min, stir for 1.5h to dissolve, then adjust the pH to 4.5 , filtered to obtain chitosan lactic acid solution. Dissolve 800.3g of Tween and 0.1g of n-octanol in ethanol solution respectively to form a 5% ethanol solution. Under stirring, slowly add n-octanol solution with a micro-injection needle, then add Tween solution, and stir until the solution is clear. Fill it and serve. Seal immediately after bottling, and fill in a workshop with a cleanliness level of 100,000. The volume of each bottle should not be less than the marked volume of 20mL / bottle. (Preparation technology roadmap see figure 1 )

[0038] How to use: Chitosan spray film is evenly sprayed at a position 10-15c...

Embodiment 2

[0039] The preparation of embodiment 2 chitosan spray film of the present invention

[0040] Dissolve 1g of lactic acid in 1000g of purified water to make a 0.1% lactic acid solution; weigh 5g of chitosan (molecular weight 10W), disperse it on the surface of the 0.1% lactic acid solution and swell for 50min, stir for 2h to dissolve, adjust the pH to 5, and filter to obtain Chitosan lactic acid solution. Dissolve 802g of Tween and 1.2g of n-octanol in ethanol solution respectively to form a 5% ethanol solution. Under stirring, slowly add n-octanol solution with a micro-injection needle, then add Tween solution, stir until the solution is clear, pour Just install it.

Embodiment 3

[0041] The preparation of embodiment 3 chitosan spray film of the present invention

[0042] Dissolve 5g of lactic acid in 2500g of purified water to make a 0.2% lactic acid solution; weigh 3.75g of chitosan (molecular weight 30W), disperse it on the surface of the 0.2% lactic acid solution and swell for 50min, stir for 1h to dissolve, adjust the pH to 4, filter, To obtain chitosan lactic acid solution. Dissolve 805g of Tween and 4.8g of n-octanol in ethanol solution respectively to form a 5% ethanol solution. Under stirring, slowly add n-octanol solution with a micro-injection needle, then add Tween solution, stir until the solution is clear, pour Just install it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com