Composite photocatalyst membrane material with hierarchical pore structure and preparation method thereof

A technology of composite photocatalysis and catalyst film, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of destroying the structure of carbon nanotubes and affecting electrical conductivity, etc. Performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

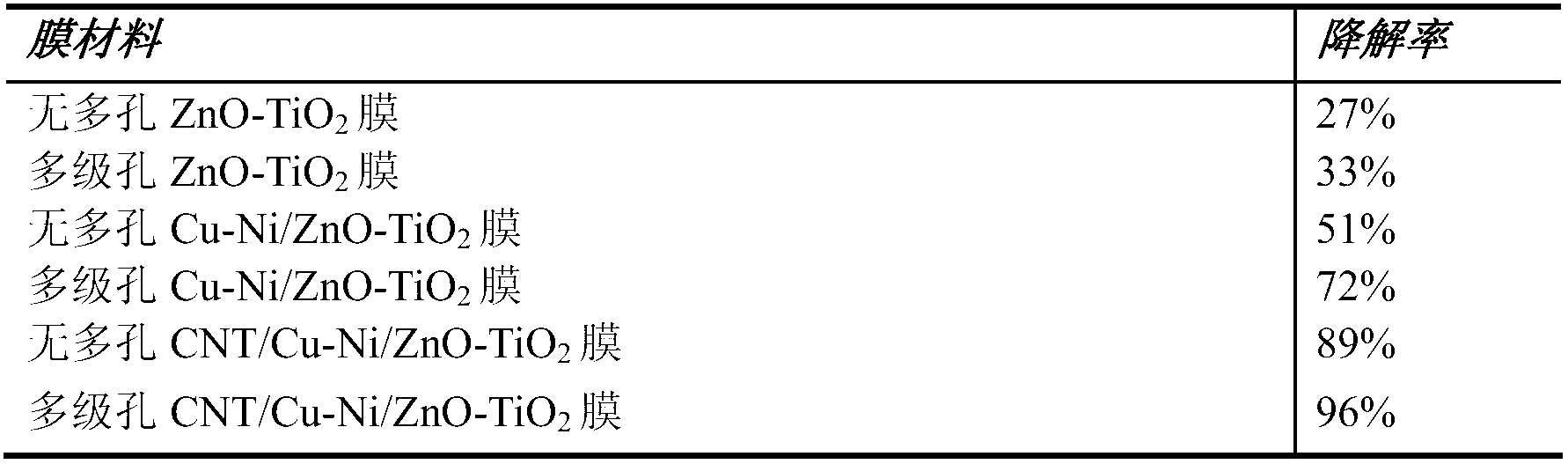

Embodiment 1

[0027] Preparation of ZnO / TiO Containing Porogens by Sol-Gel Method 2 Sol (Zn:Ti=0.2, molar ratio), weighed 2.0g F127 and 1.0g CTAB, dissolved in 37.70ml absolute ethanol, added dropwise 2.68g nitric acid, and then slowly added dropwise 6.80g tetrabutyl titanate and 0.88g zinc acetate, stir to obtain solution A; 0.15g Cu(NO 3 ) 2 ·3H 2 O and 0.17g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 21.50 ml of deionized water to obtain solution B. Add solution B dropwise to solution A, stir for 1 hour to obtain solution C, and let it stand for 10 hours to obtain ZnO / TiO containing porogen P123 and CTAB and doped with copper and nickel 2 Precursor spray liquid.

[0028] Preparation of ZnO / TiO by Spray Pyrolysis 2 Composite membrane: place the cleaned ITO on a hot stage at 350 ° C, and the above ZnO / TiO 2 The precursor spray liquid was injected into the nozzle at a rate of 0.5ml / min, and 2 (0.4L / h) under the action of spraying, spraying 5 times, the preparation of ITO loaded ZnO / TiO ...

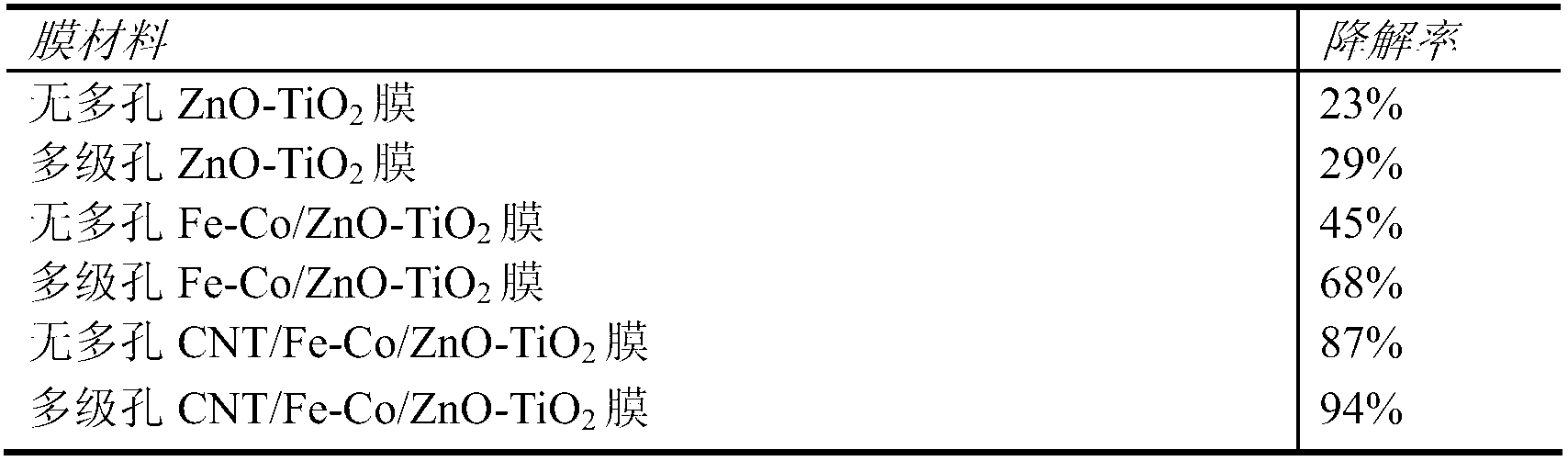

Embodiment 2

[0034] Preparation of ZnO / TiO by Sol-Gel Method 2 Sol (Zn:Ti=1:1, molar ratio), weigh 2.5g P123 and 0.2g PMMA, dissolve in 37.70ml absolute ethanol, add 2.68g nitric acid dropwise, then slowly add 6.80g tetrabutyl titanate and 4.4g zinc acetate, stir to obtain solution A; 0.04gFe(NO 3 ) 3 9H 2 O and 0.25g Co(NO 3 ) 2 ·6H 2 O was dissolved in 21.50 ml of deionized water to obtain solution B. Add solution B dropwise to solution A, stir for 2 hours to obtain solution C, and after standing for 48 hours, obtain TiO containing P123 and doped with iron and cobalt 2 Precursor gel. Using the scraper method, the gel was assembled on the Ni sheet, and then the Ni sheet was placed in a muffle furnace, heated to 350°C at a rate of 3°C / min, baked for 3 hours, and then heated to 500°C at a rate of 5°C / min. ℃, baked for 3 hours.

[0035] ZnO / TiO modified by co-doping the above transition metal iron and cobalt 2 The composite membrane is placed in a fixed bed reactor. The reactor wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com