Method for removing free ammonia in urea powder

A technology for free ammonia and urea, which is applied in urea compound fertilizer, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of ammonia escape from urea granulation tower, avoid low removal efficiency, good effect, and enhance functionality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

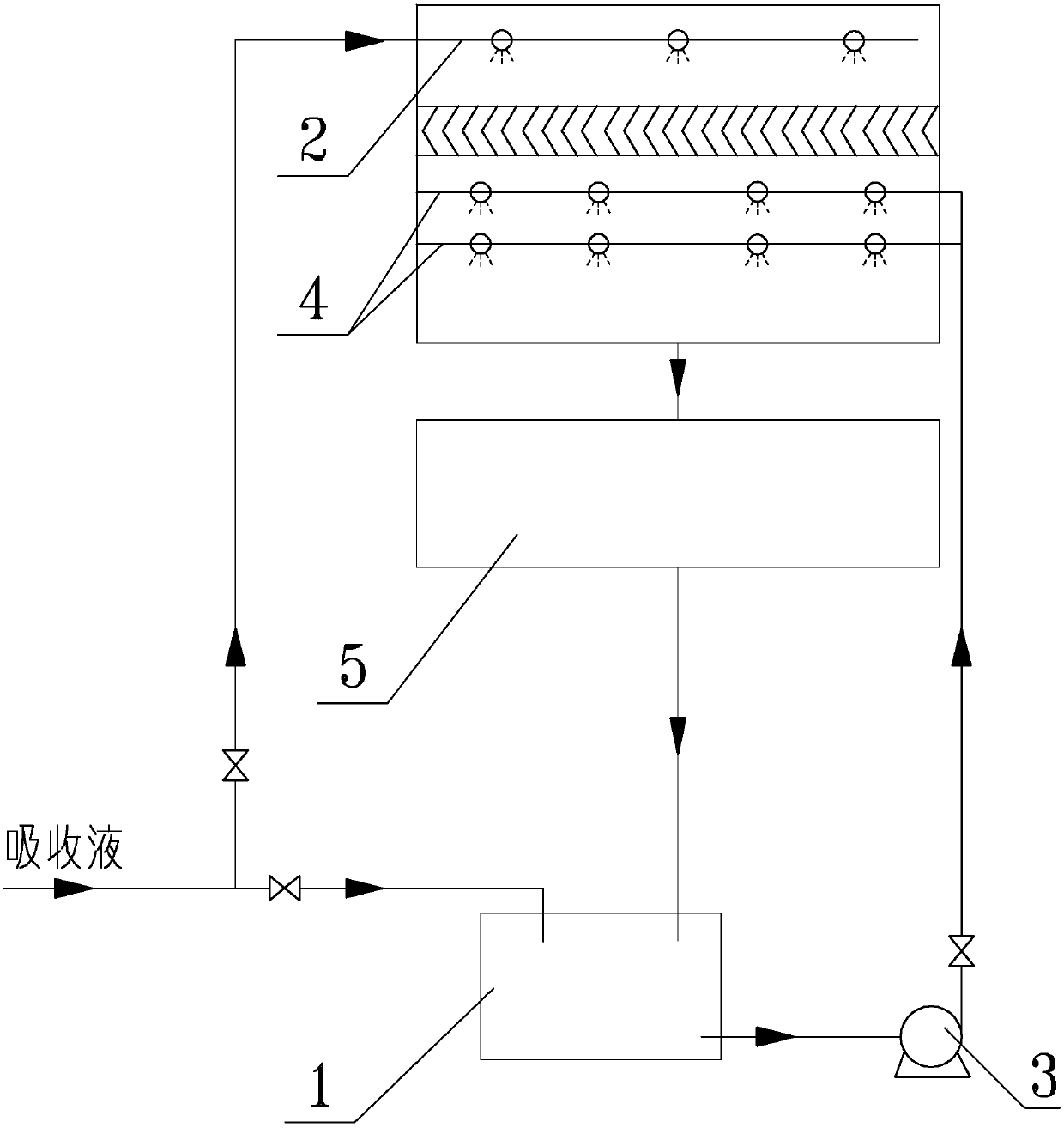

Method used

Image

Examples

Embodiment 1

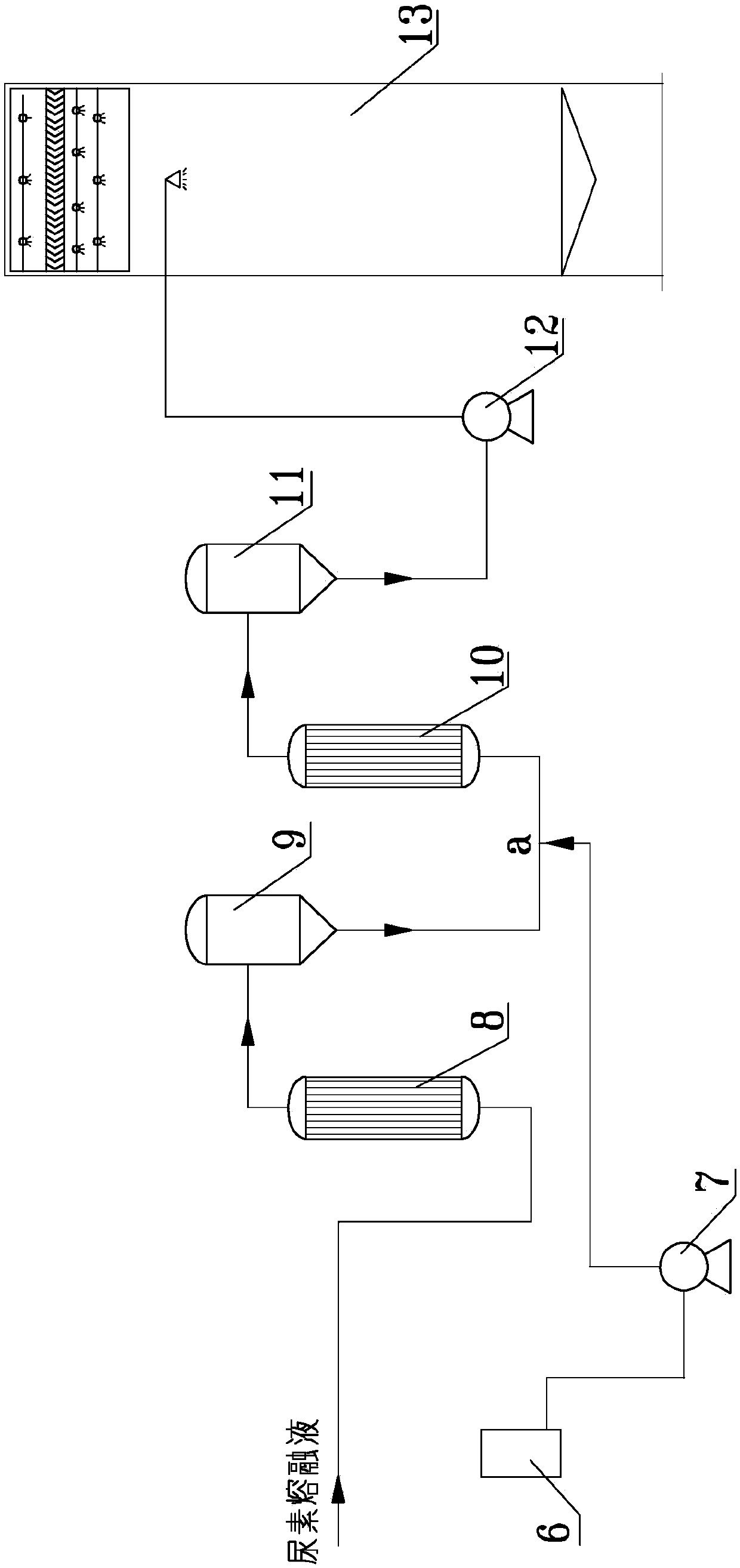

[0027] Embodiment 1: as figure 2 Shown, the present invention removes the method for free ammonia in urea dust and comprises the steps:

[0028] a. The urea melt is heated and concentrated in the first-stage evaporator 8, gas-liquid separated in the first-stage separator 9, further heated and concentrated in the second-stage evaporator 10, and gas-liquid separated again in the second-stage separator 11, and then fed into the melting pump 12 to fully mix and add pressure;

[0029] b. According to the content of free ammonia in the urea melt, the prepared sulfuric acid aqueous solution (or nitric acid, hydrochloric acid, phosphoric acid, H 2 CO 3 Inorganic acid aqueous solution or organic acid aqueous solution such as lactic acid, formic acid, acetic acid, oxalic acid, citric acid, malic acid) passes through the acid storage tank 6 and then is pumped into the pipeline a between the first-stage evaporation separator 9 and the second-stage evaporator 10 through the metering pum...

Embodiment 2

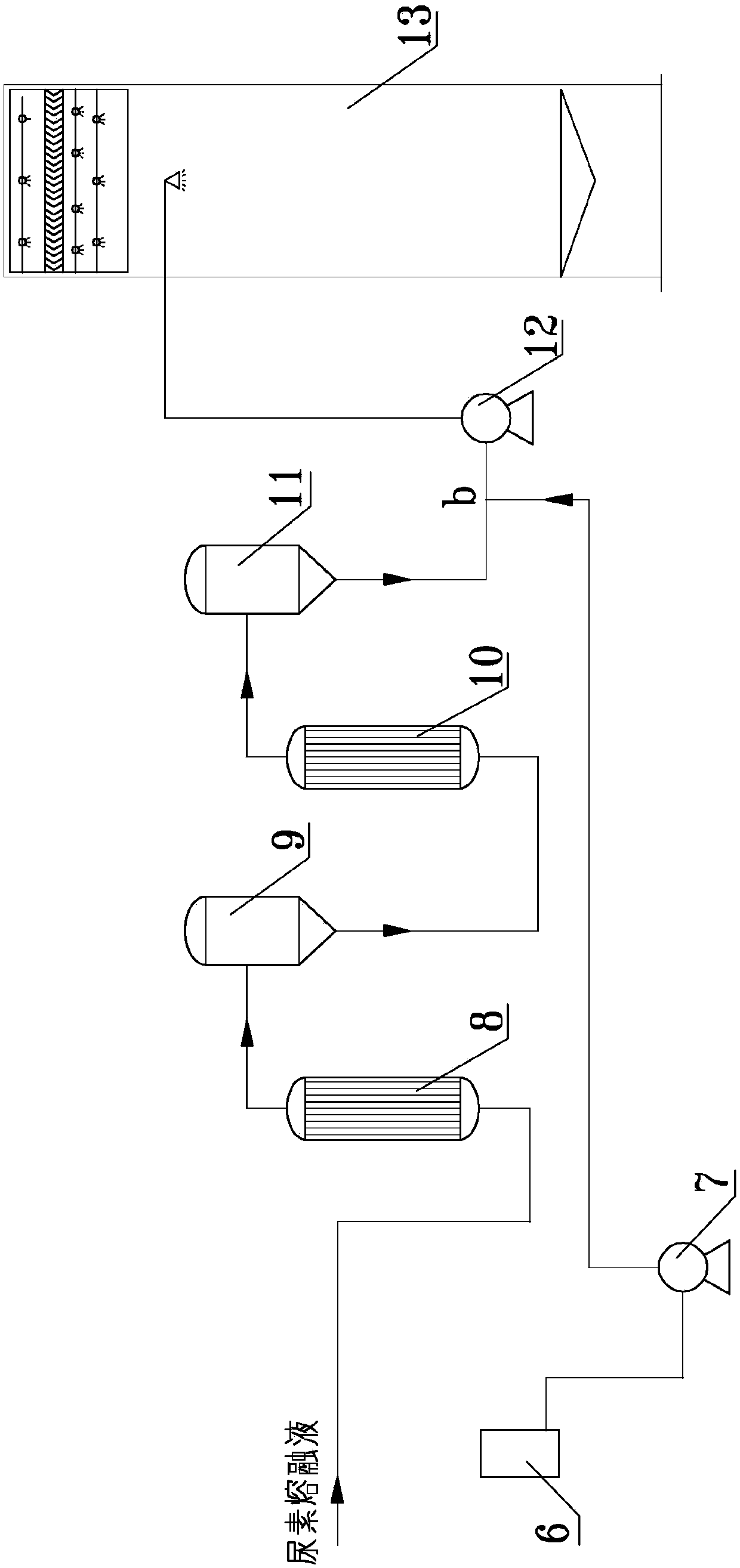

[0031] Embodiment 2: as image 3 As shown, the difference between this embodiment and embodiment 1 is:

[0032] a. The urea melt enters the melt pump 12 after passing through the first-stage evaporator 8, the first-stage separator 9, the second-stage evaporator 10 and the second-stage separator 11 in sequence;

[0033] b. According to the content of free ammonia in the urea melt, the prepared sulfuric acid aqueous solution (or nitric acid aqueous solution or hydrochloric acid aqueous solution or phosphoric acid aqueous solution or carbonic acid and other inorganic acids or organic acids such as lactic acid, formic acid, acetic acid, oxalic acid, citric acid and malic acid) Aqueous solution) passes through the acid storage tank 6 and is pumped into point b of the pipeline between the second-stage evaporation separator 11 and the melting pump 12 through the metering pump 7, and the added acid solution and urea melt are mixed in the pipeline to neutralize the urea in the solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com