Dry method for preparing intercalation compound of monotomorillonite/urea

A technology of intercalation composite and montmorillonite, which is applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve problems such as redundant step aggregation, and achieve large surface layer spacing, simple process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

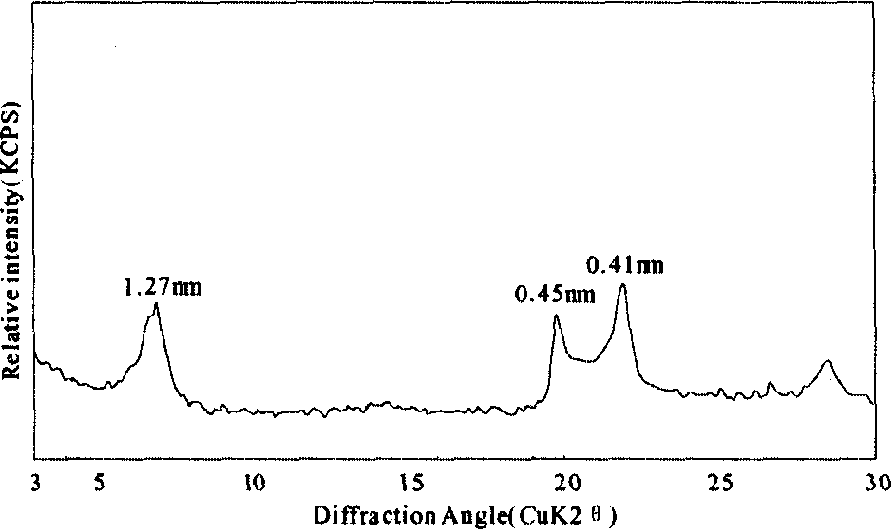

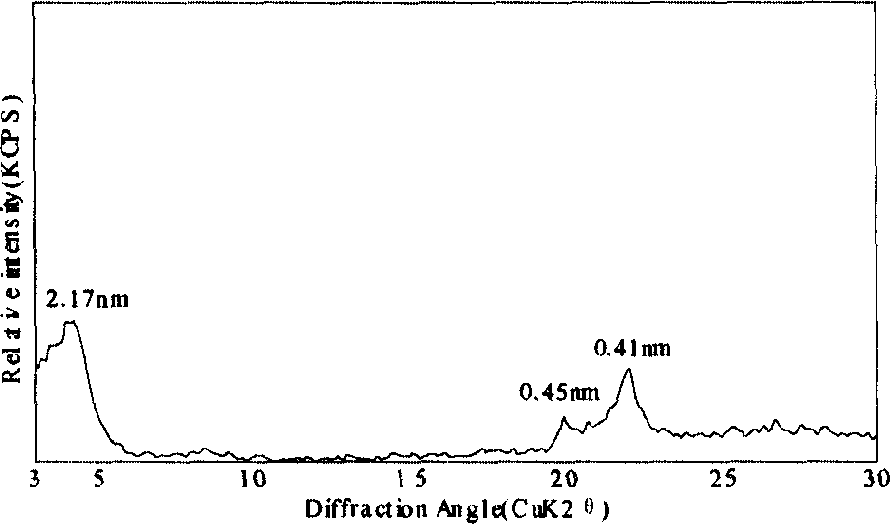

[0023] 30Kg, less than 45 μm (less than 325 orders), Henan Xinyang sodium-based montmorillonite powder ( figure 1 ) and 3Kg of urea powder were mixed uniformly, put into an oven, and kept at a constant temperature between 90 and 120°C for 3 hours to obtain a montmorillonite / urea intercalation compound ( figure 2 ), by X-ray diffraction (XRD) line figure 1 and figure 2 It can be seen that the original (001) interlayer spacing of Na-montmorillonite is 1.27nm, and after intercalation of urea molecules, it expands to 2.17nm.

[0024] The temperature of the oven or mixer should not be higher than 132°C, otherwise the urea molecules entering the interlayer of montmorillonite will be decomposed. The content of urea cannot exceed 30% of the weight of the montmorillonite, and excess urea cannot enter between layers of the montmorillonite crystal structure, and can only be adsorbed on the surface of the montmorillonite.

Embodiment 2

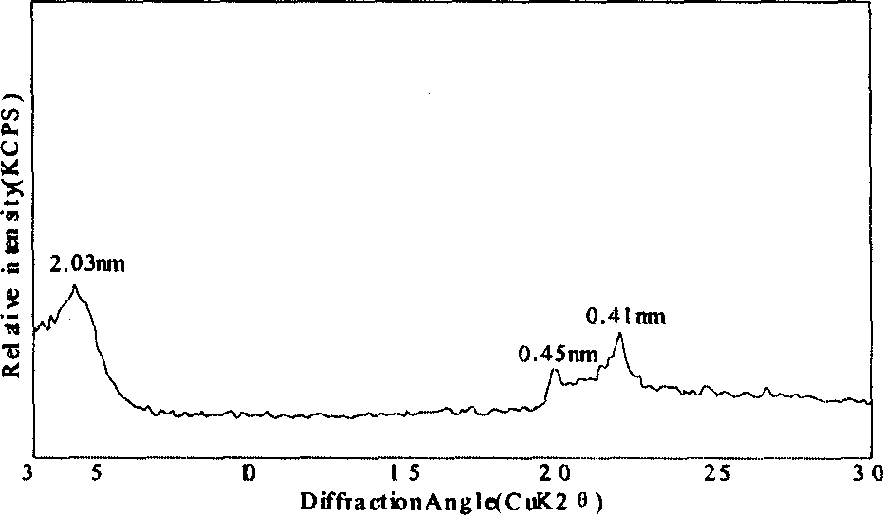

[0026] Mix 50Kg of Henan Xinyang Na-based montmorillonite powder with a thickness of less than 45μm and a montmorillonite content of about 90% and 10Kg of urea powder evenly, put them in an oven, and keep the temperature between 90 and 120°C for 3 hours to obtain urea / Montmorillonite intercalation complex ( image 3 ), the interlayer spacing of the montmorillonite (001) surface expanded from 1.27nm to 2.03nm.

Embodiment 3

[0028] Mix 2Kg of Henan Xinyang Na-based montmorillonite powder with a thickness of less than 45μm and a montmorillonite content of about 90% and 0.2Kg of urea powder, put them in an oven, and keep the temperature at 90-120°C for 1 hour to obtain urea / montmorillonite intercalation complex( Figure 4 ), the interlayer spacing of the (001) surface of montmorillonite expanded from 1.27nm to 1.83nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com