Urea granulating column with high yield

A urea granulation tower, high yield technology, applied in the direction of urea compound fertilizer, liquid into beads granulation, mold extrusion granulation, etc., can solve the problem of low temperature of molten urea, to increase the contact area, trajectory Stable and outstanding effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

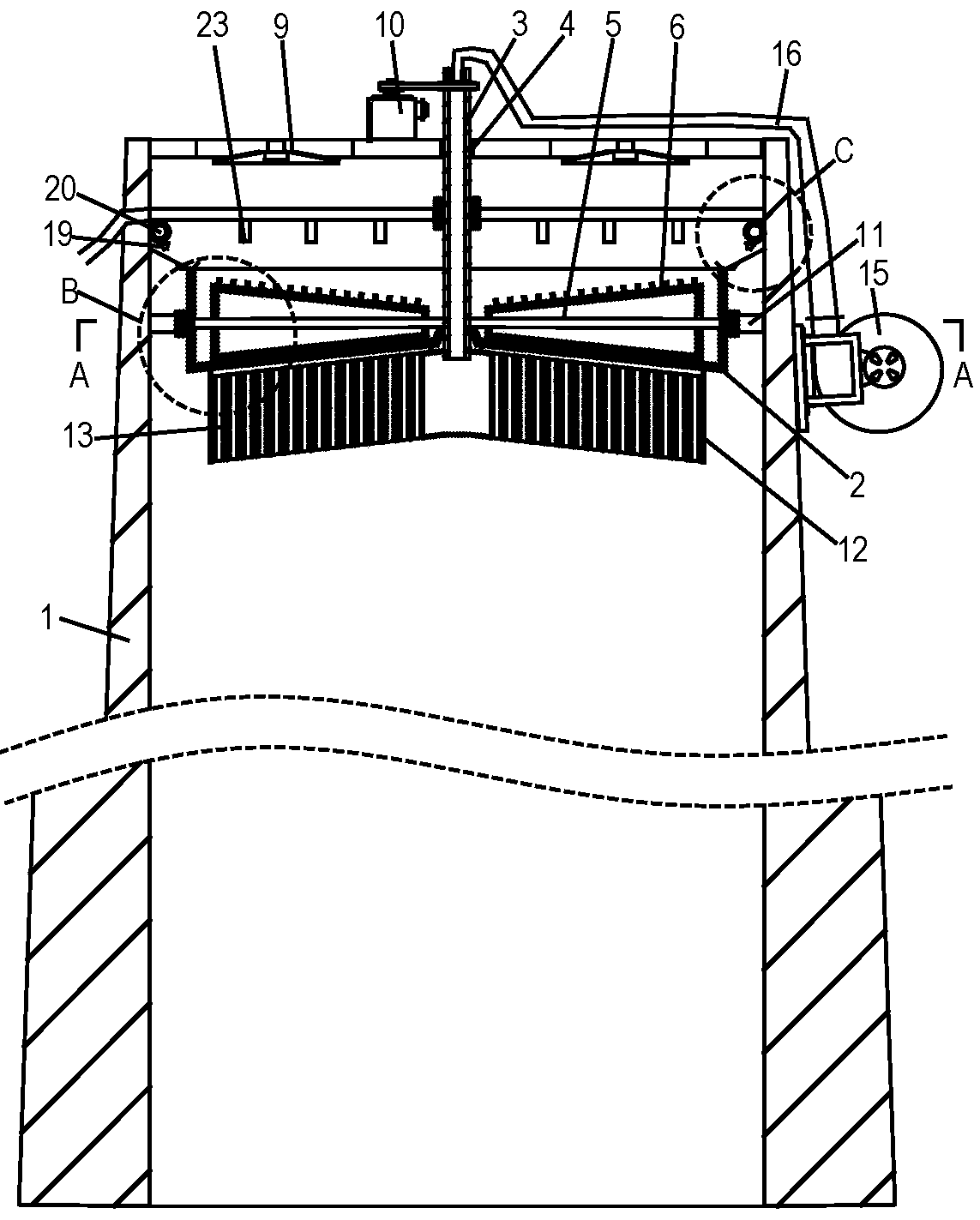

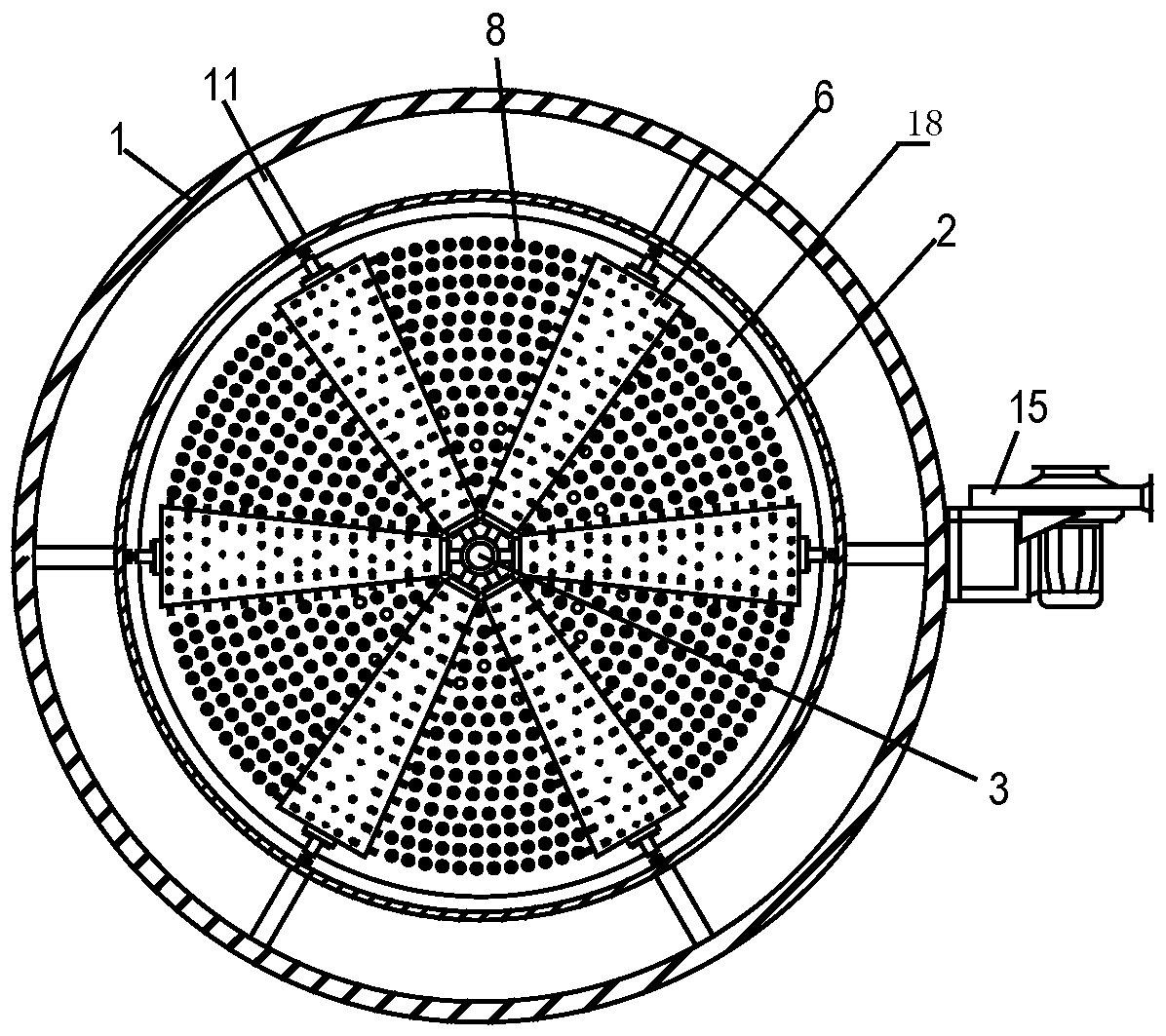

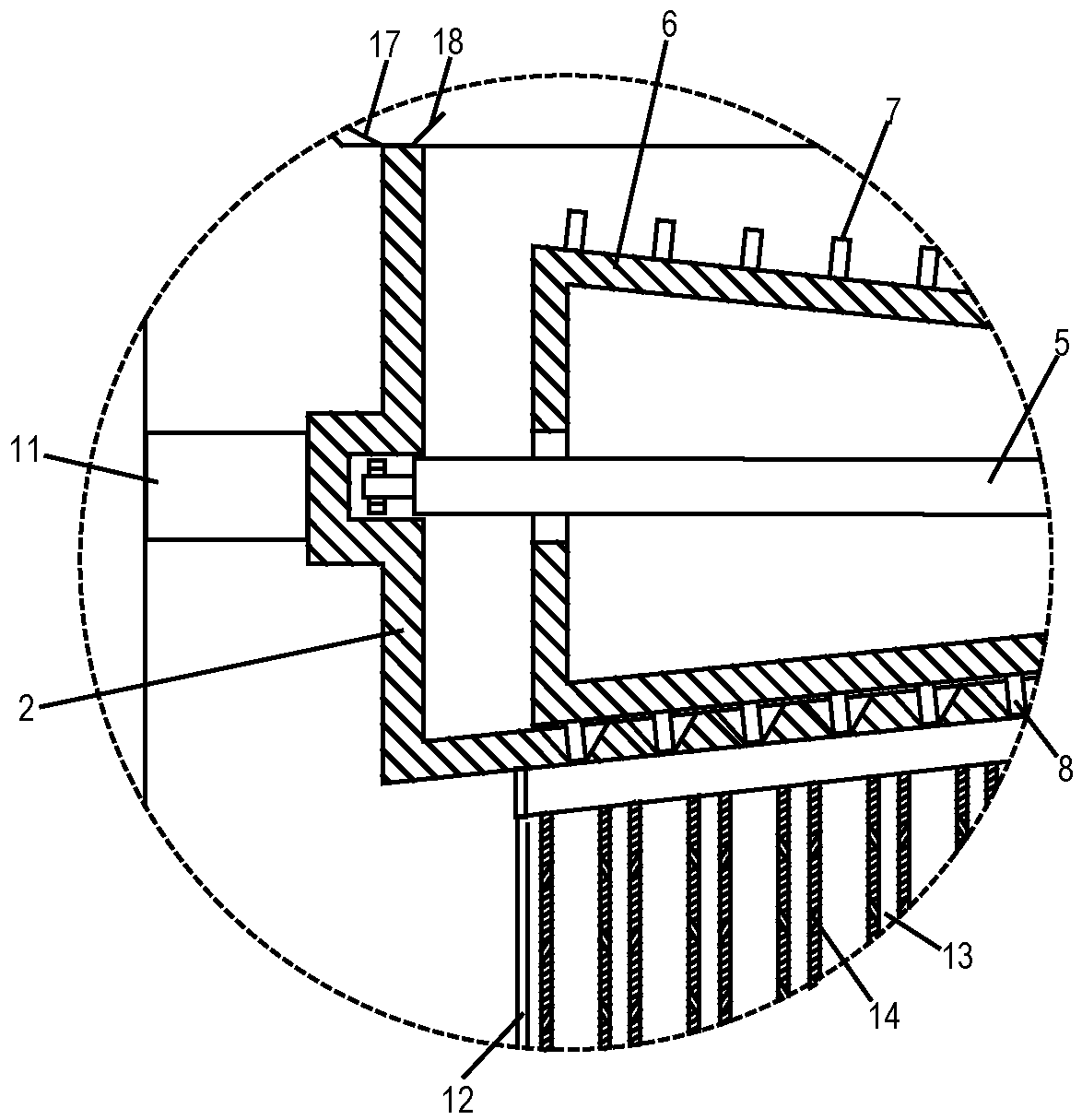

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1-Figure 5 As shown, the high-yield urea prilling tower related to the present invention includes a tower body 1 and a distributor, and also includes a material extrusion pan 2, which is arranged on the upper part of the tower body 1, and the extrusion material The disc 2 is in the shape of a container, and a hollow shaft 3 is arranged in the middle of the extruding disc 2. The hollow shaft 3 passes through the extruding disc 2 and is perpendicular to the extruding disc 2. The positions are respectively provided with collars 4, and the hollow shaft 3 is installed in the two collars 4, and six horizontal central shafts 5 are evenly distributed and fixed on the outer side of the hollow shaft 4, and each central shaft 5 is respectively worn and hinged. Extrusion rollers 6, the bottom edge of each extrusion roller 6 fits with the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com