Patents

Literature

39results about How to "Trajectory stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

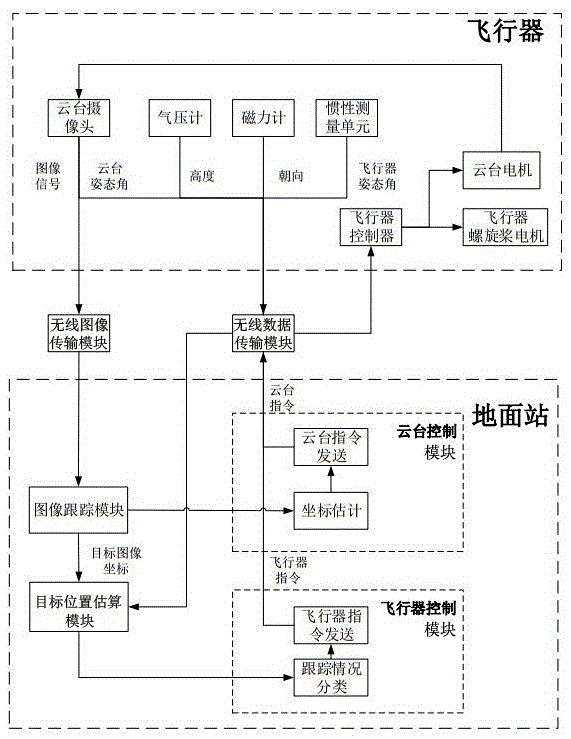

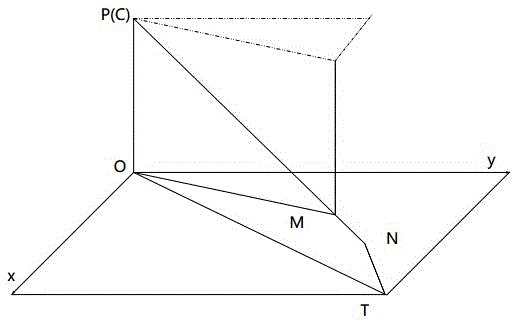

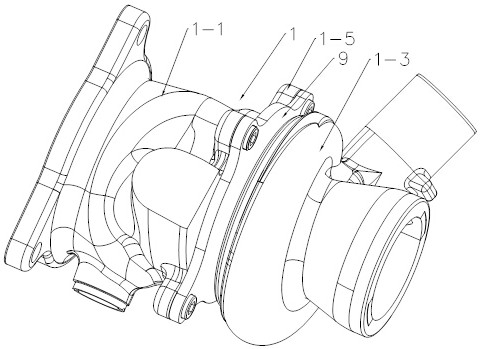

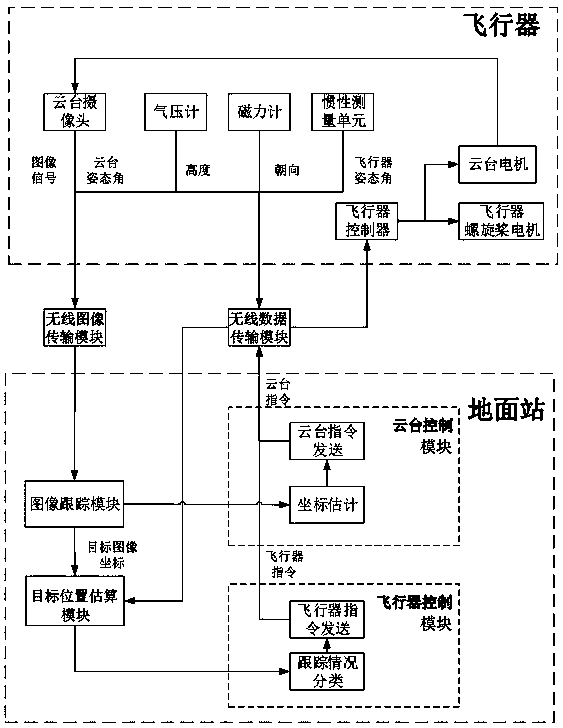

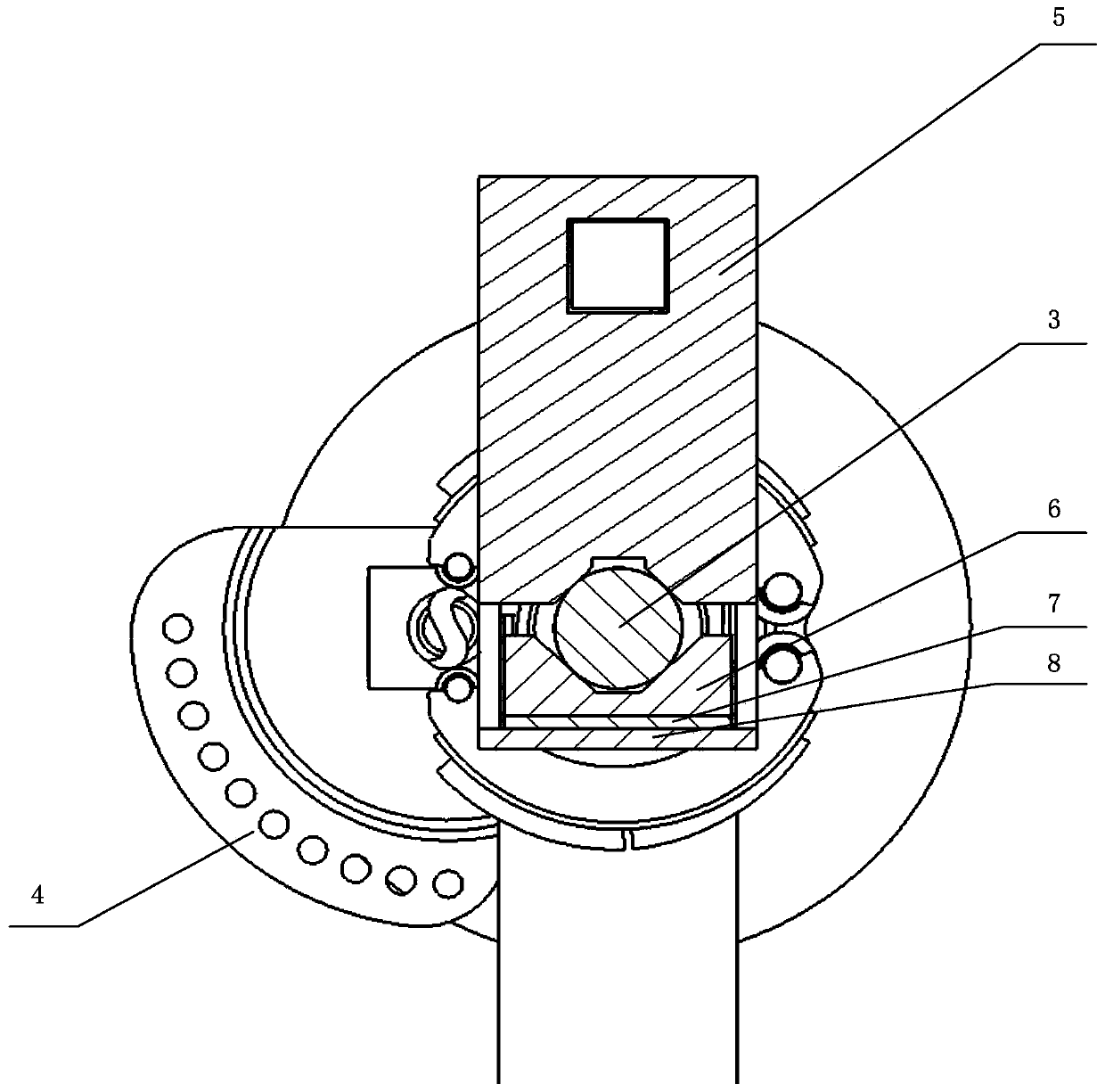

Unmanned gyroplane moving target autonomous tracking device and control method thereof

ActiveCN105652891AImprove real-time performanceImprove smoothnessTarget-seeking controlPropellerFlight vehicle

The invention relates to the technical field of unmanned gyroplane autonomous tracking, in particular to an unmanned gyroplane moving target autonomous tracking device based on a pan-tilt camera and an airborne sensor. The unmanned gyroplane moving target autonomous tracking device comprises an aircraft and a ground station. The aircraft comprises an aircraft controller, an aircraft propeller motor connected with the aircraft controller, and a pan-tilt motor. The pan-tilt motor is connected with the pan-tilt camera. A wireless image transmission module and a wireless data transmission module are arranged between the aircraft and the ground station. The aircraft and the ground station are connected through the wireless image transmission module and the wireless data transmission module. Images obtained by the airborne pan-tilt camera serve as input of a system, coordinates of a target in the images are obtained on the ground station through a Struck algorithm, modeling is conducted on the coordinates of the target through a uniformly accelerated motion (CA) model, the control quantity of a pan-tilt is designed according to the coordinates, estimated through modeling, of the target, and accordingly tracking instantaneity and smoothness of the pan-tilt camera are guaranteed.

Owner:SUN YAT SEN UNIV

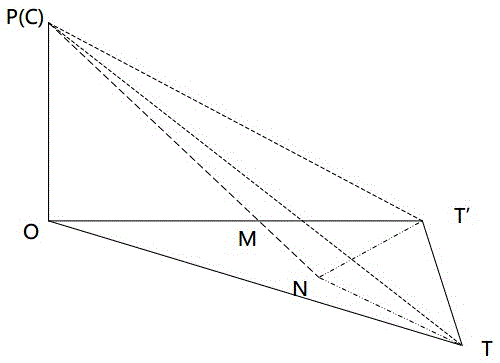

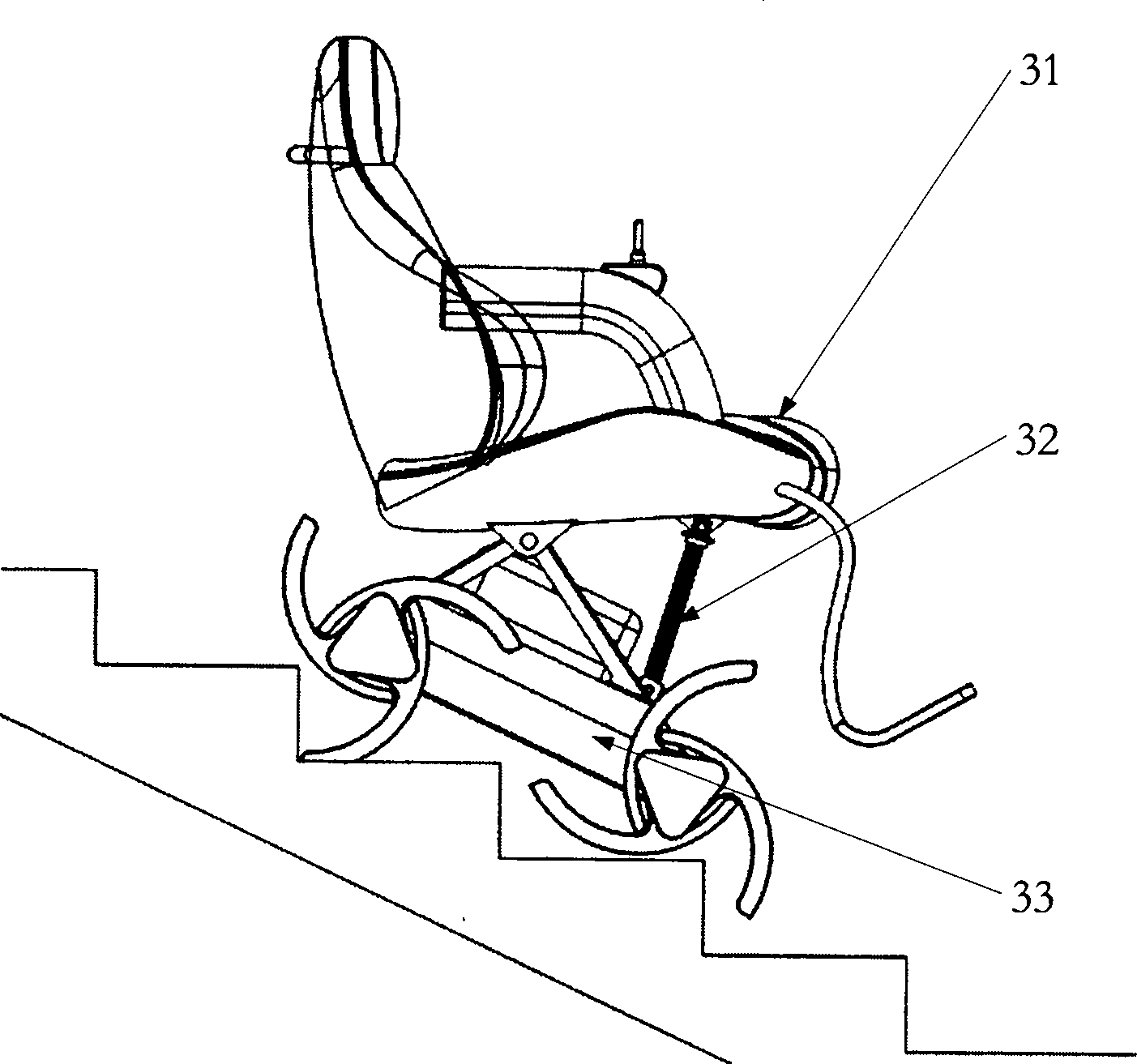

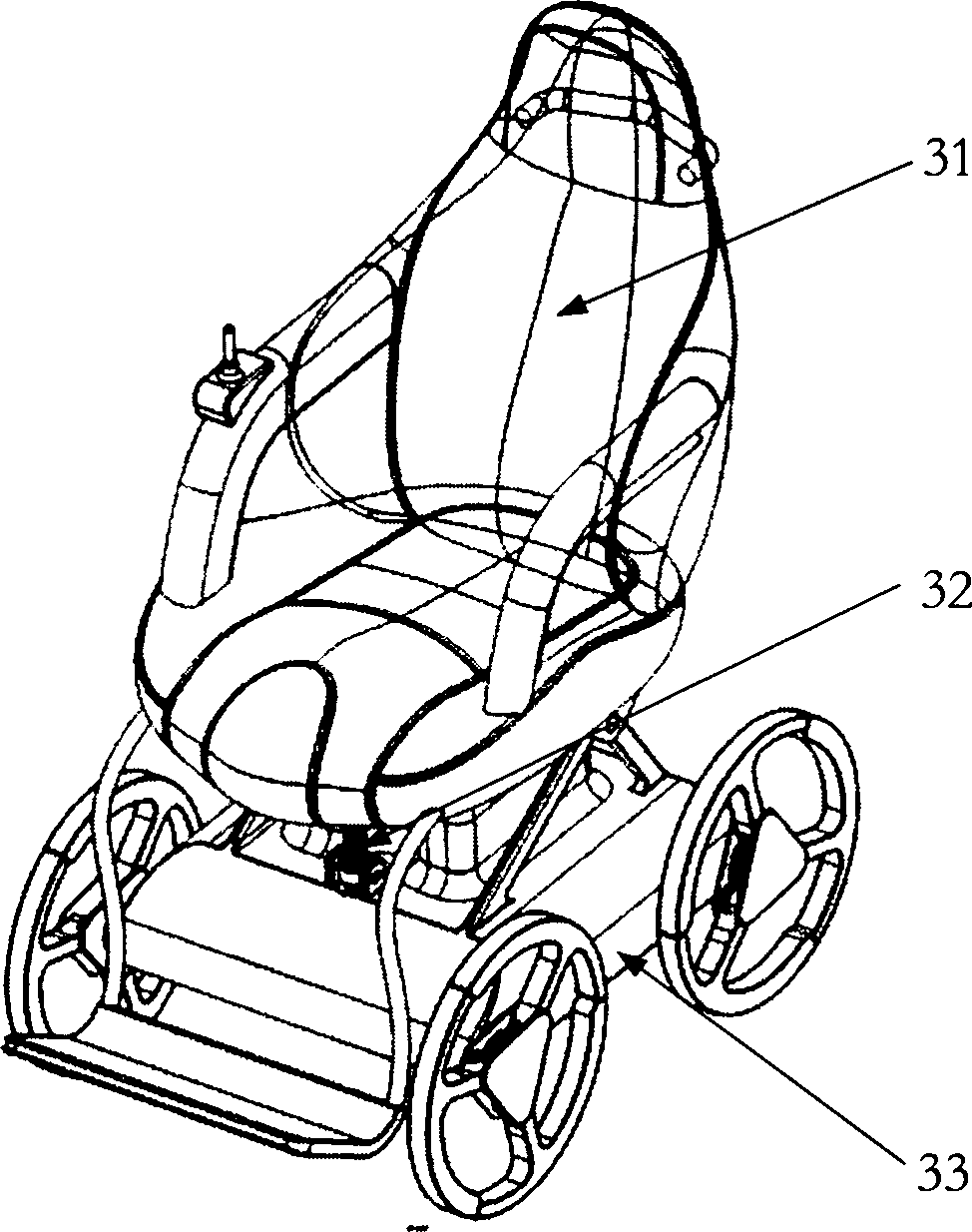

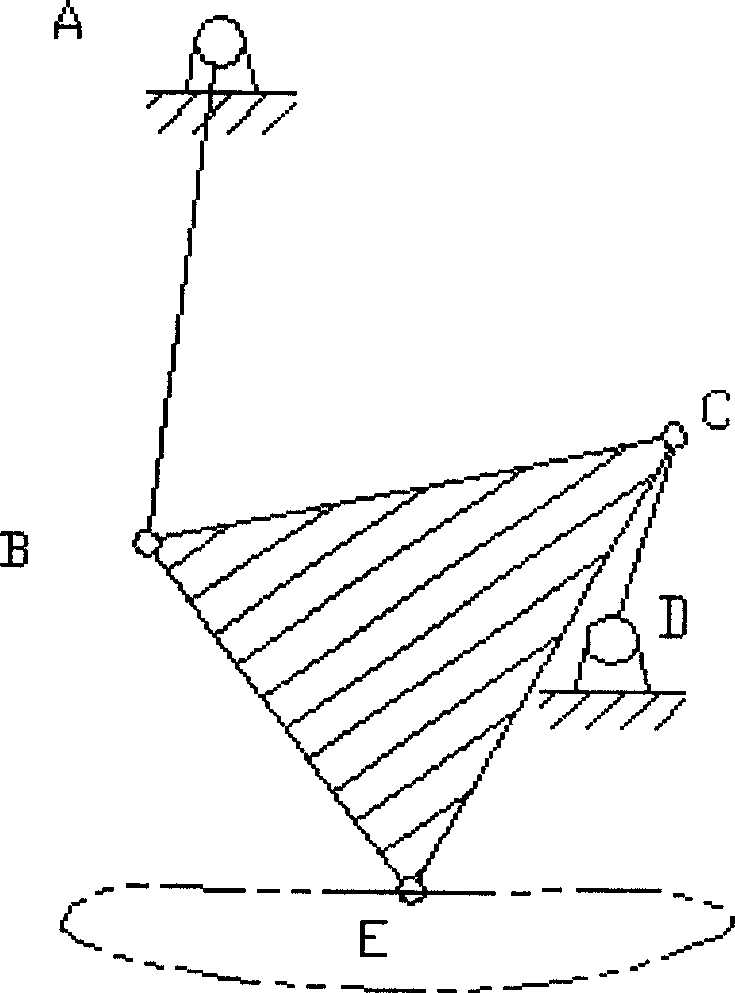

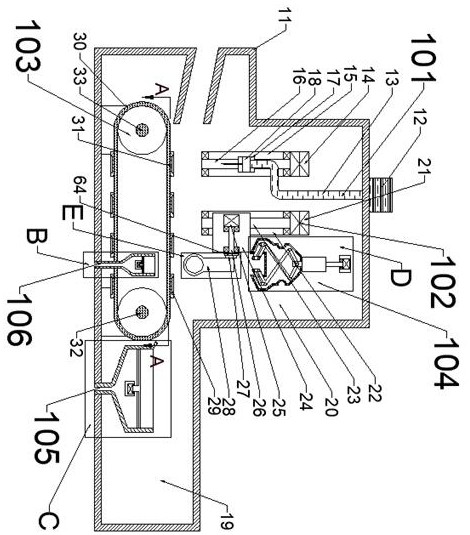

Wheelchair capable of climbing stairs

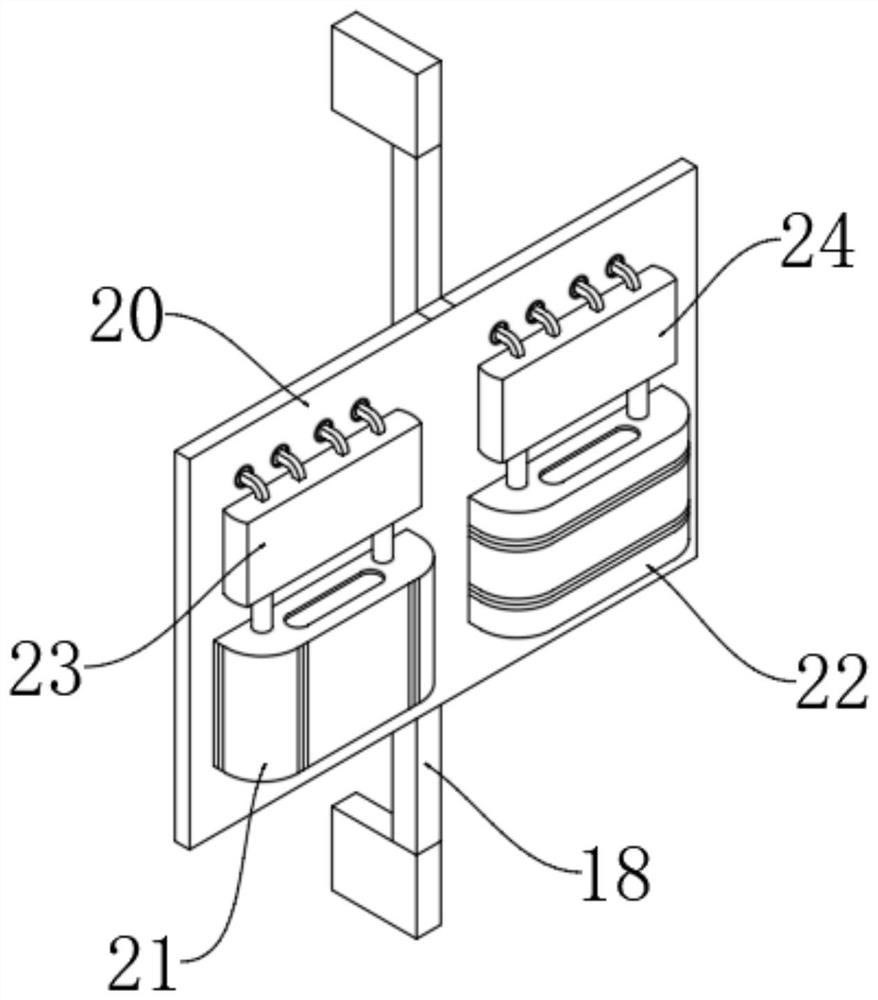

InactiveCN102860906ASmooth continuous motionImprove bearing capacityWheelchairs/patient conveyanceEffective solutionImpeller

The invention discloses a wheelchair capable of climbing stairs smoothly and running on flats. The wheelchair comprises a chair, a lifting device and a running part, wherein the running part is used for bearing the chair, the balance of the chair is kept under the action of the lifting device, the running part consists of a planetary wheel mechanism and a differential drive system, four working states of the wheelchair can be achieved through the combination of the planetary wheel mechanism and the differential drive system and the four working states comprise running on flats, turning on flats, stair descending and climbing and the shift between stairs and flats. The wheelchair is provided with two sets of drive mechanisms, an electric motor drives a central shaft through a straight-tooth cone gear, a planet carrier is driven through a clutch on the central shaft, and stretching and keeping of an impeller are achieved through transfer and linkage of the clutch and an arrester, i.e., differential and identical speed of the central shaft and the planet carrier. The wheelchair is adapted to prior stairs, runs stably and continuously, is good in bearing capacity and can run on flats. By the aid of the wheelchair, the living trip of the elderly and disabled persons is achieved.

Owner:谢哲

Five foot wall climbing robot

InactiveCN1511681AStable supportSmall ups and downsProgramme-controlled manipulatorControl systemReducer

The five-foot wall climbing robot as one small robot consists of frame, leg mechanism, driving mechanism and control system, and has five feet with adsorbing electromagnet. Its frame consists of front frame and back frame, the front frame is provided with straight motor and reducer combination and has on the output shaft two symmetric and synchronous sets of leg mechanisms and electromagnets, and the back frame is also provided with straight motor and reducer combination and has on the output shaft two symmetric and synchronous sets of leg mechanisms and electromagnets. The front frame and the back frame capable of rotating and floating are driven with a middle turning motor, and the leg mechanism is four-link rod mechanism. The robot is novel in structure, simple, small and smart, can crawl and turn on plane in any inclination and may be used in job in narrow space and dangerous area.

Owner:DALIAN UNIV OF TECH

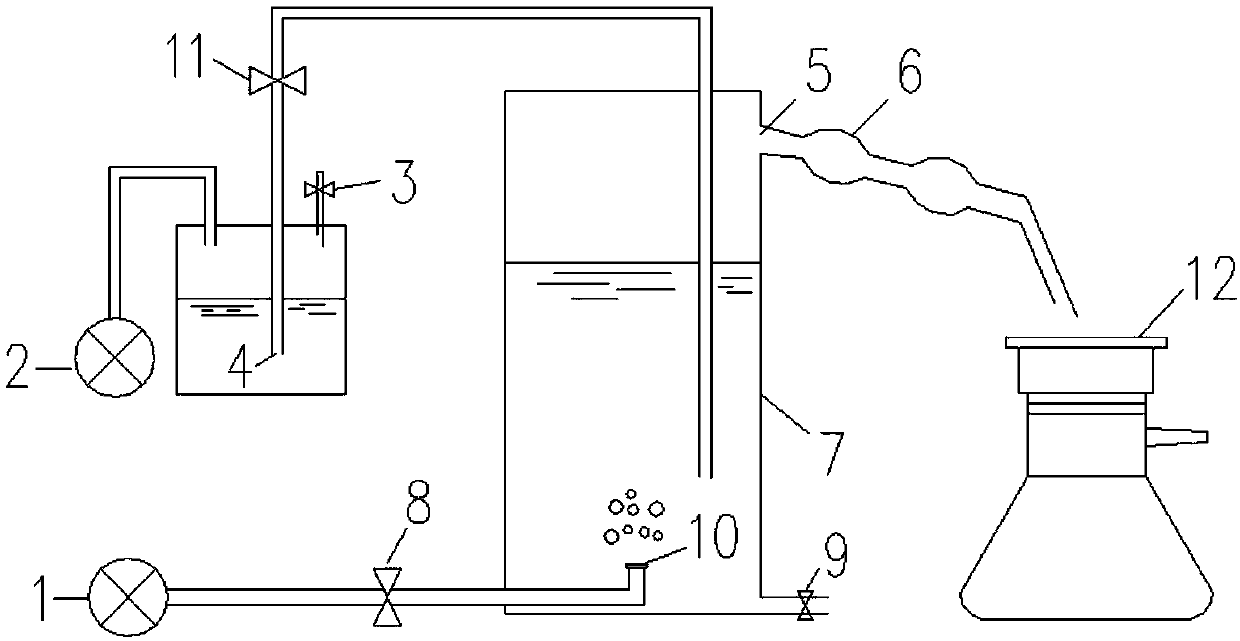

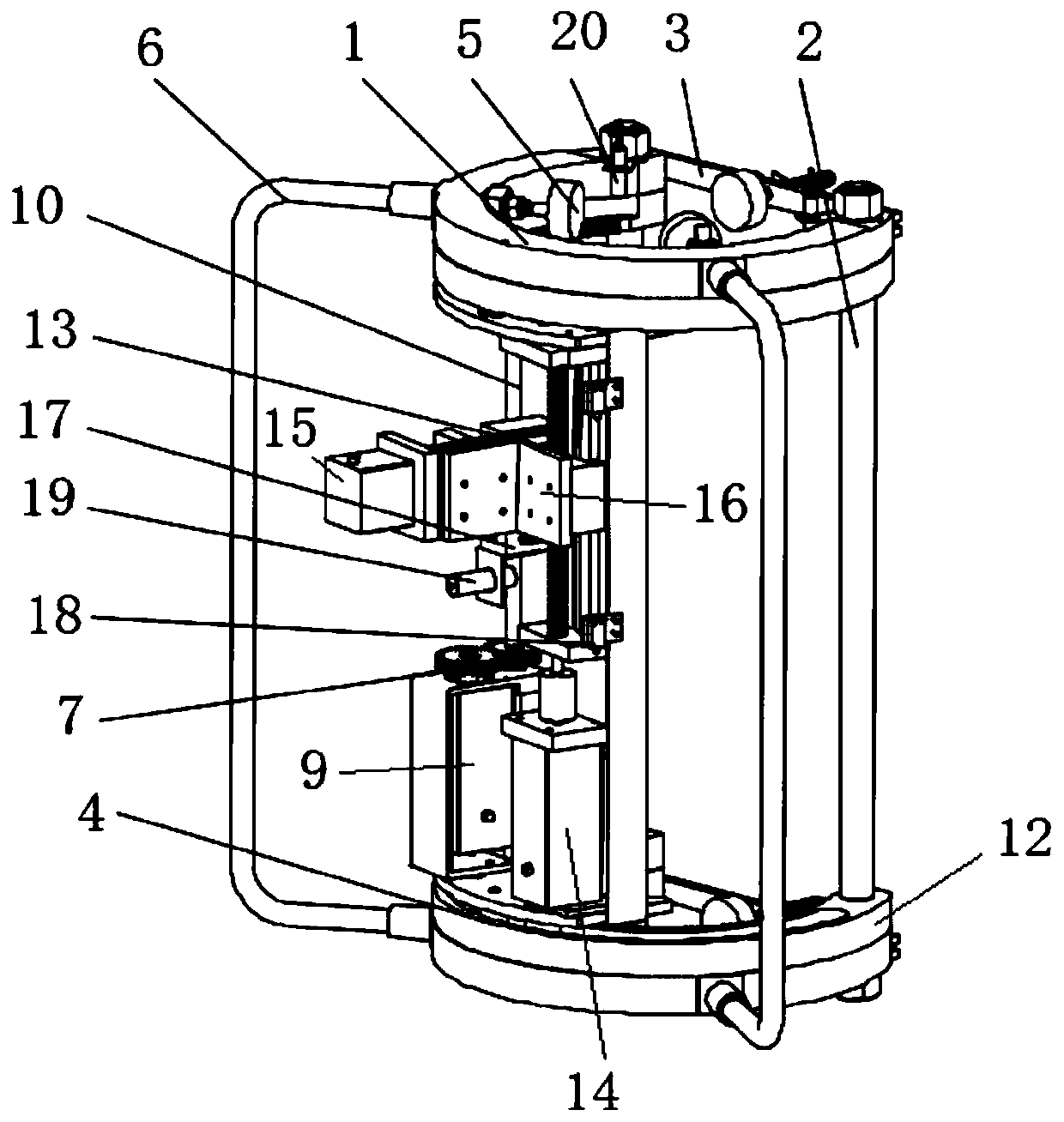

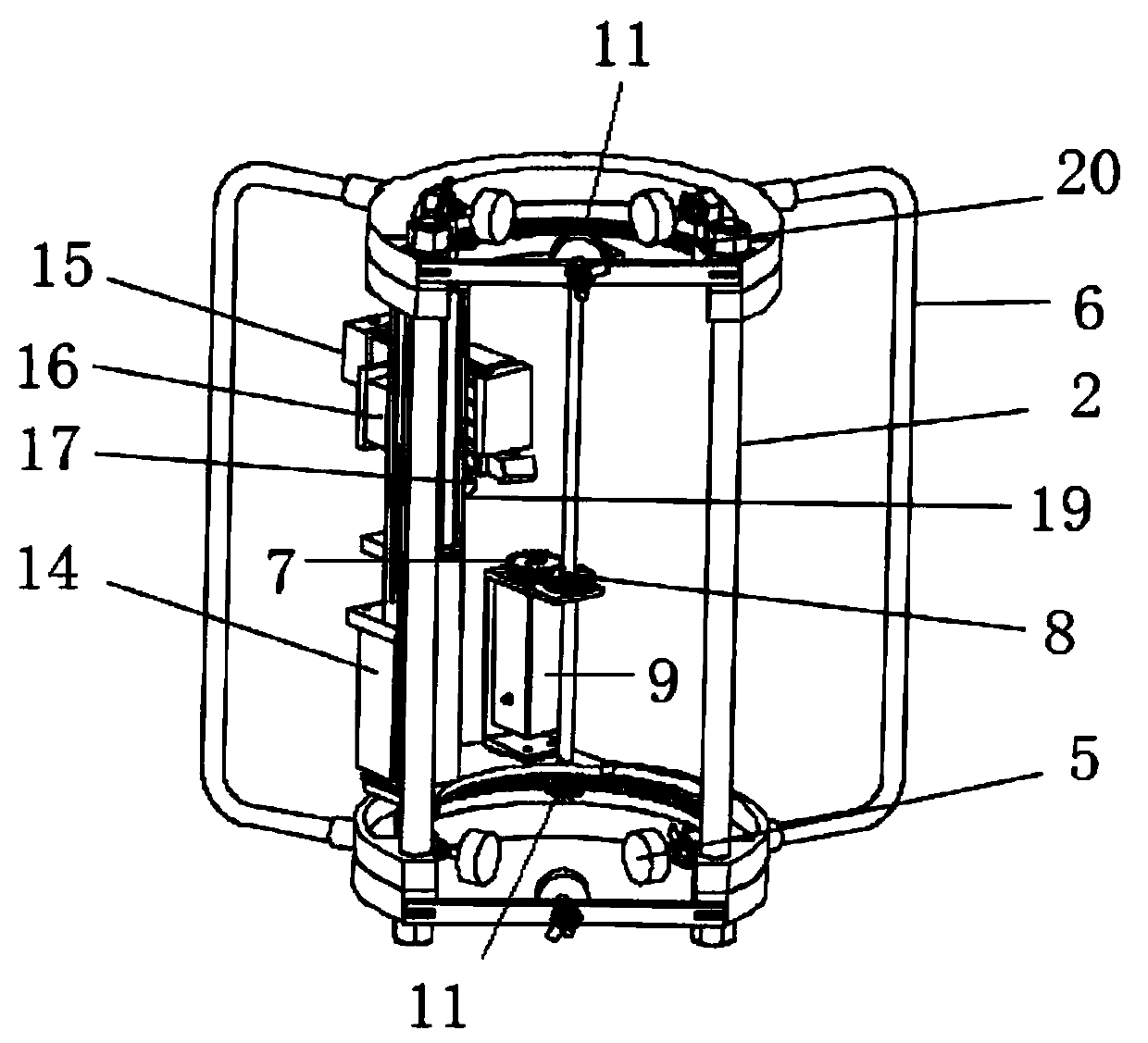

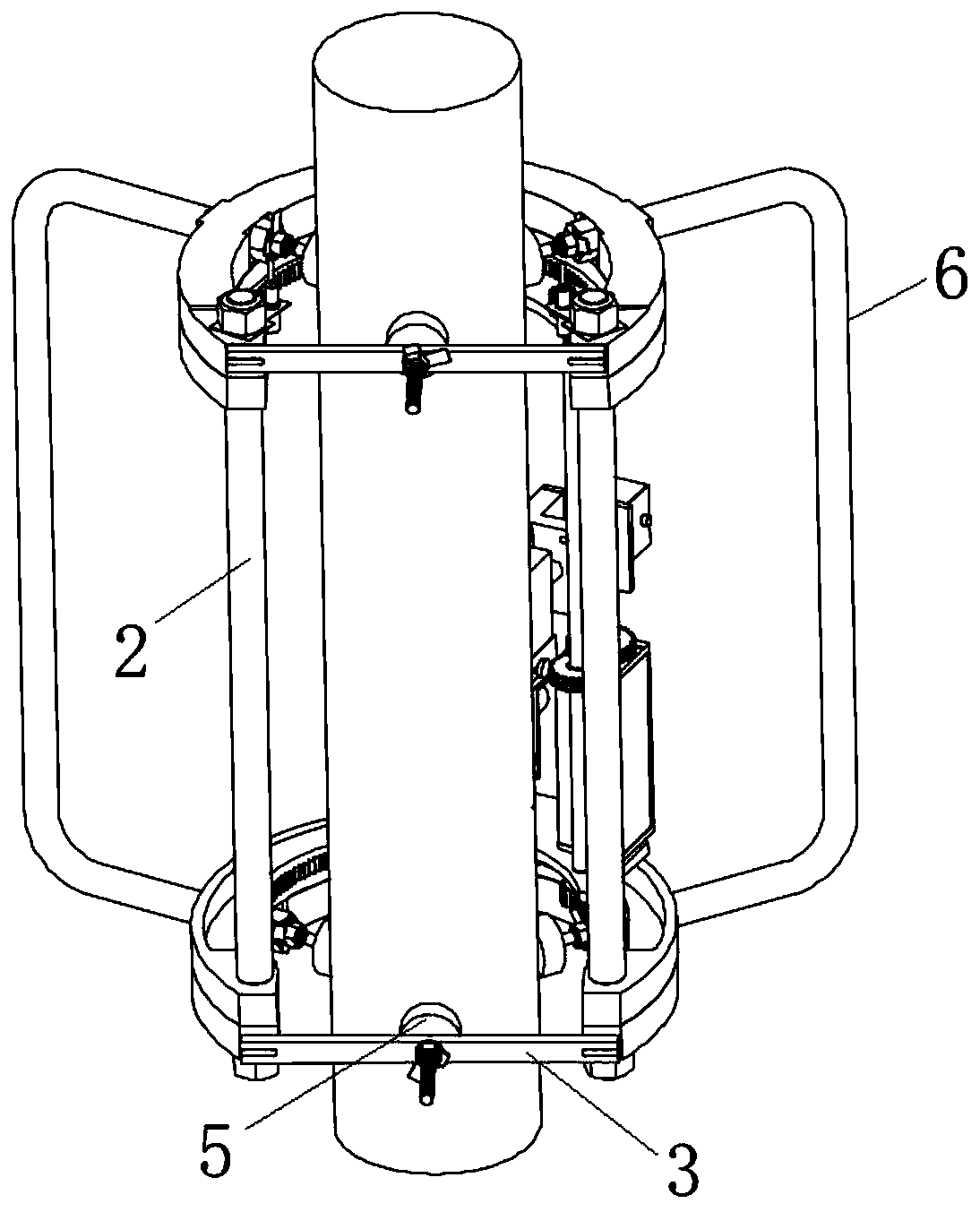

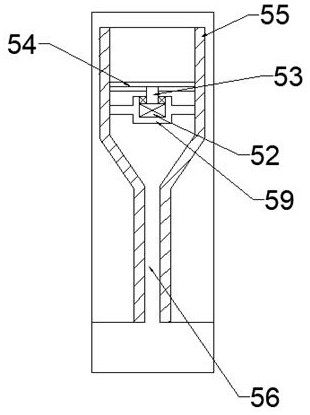

Flotation gathering device and screening method for microplastics

InactiveCN109655321AImprove extraction efficiencyReduce demandPreparing sample for investigationHigh densityAeration system

The invention discloses a flotation gathering device and a screening method for microplastics. The basic principle is that the difference of adhesion characteristics of bubbles on hydrophilic and hydrophobic materials can be changed based on a biosurfactant, and a high-density flotation solution can improve the separation effect on the high-density microplastics. The device comprises a flotation solution storage device, a separation pipe, an aeration device and a suction filtration device, wherein the aeration system is used for generating ascending gas to strengthen stirring of the system, and microplastics are coated with small bubbles to be rapidly separated. After standing, the flotation solution is pushed by a flotation solution system to overflow from an upper opening, and the separation performance of the microplastics is improved. The microplastic flotation separation device disclosed by the invention is simple and easy to operate, high in recovery rate of microplastic particlefragments, recyclable in flotation liquid, high in practicability and low in cost, and can be widely applied to gathering and screening of environmental microplastics.

Owner:TIANJIN UNIV

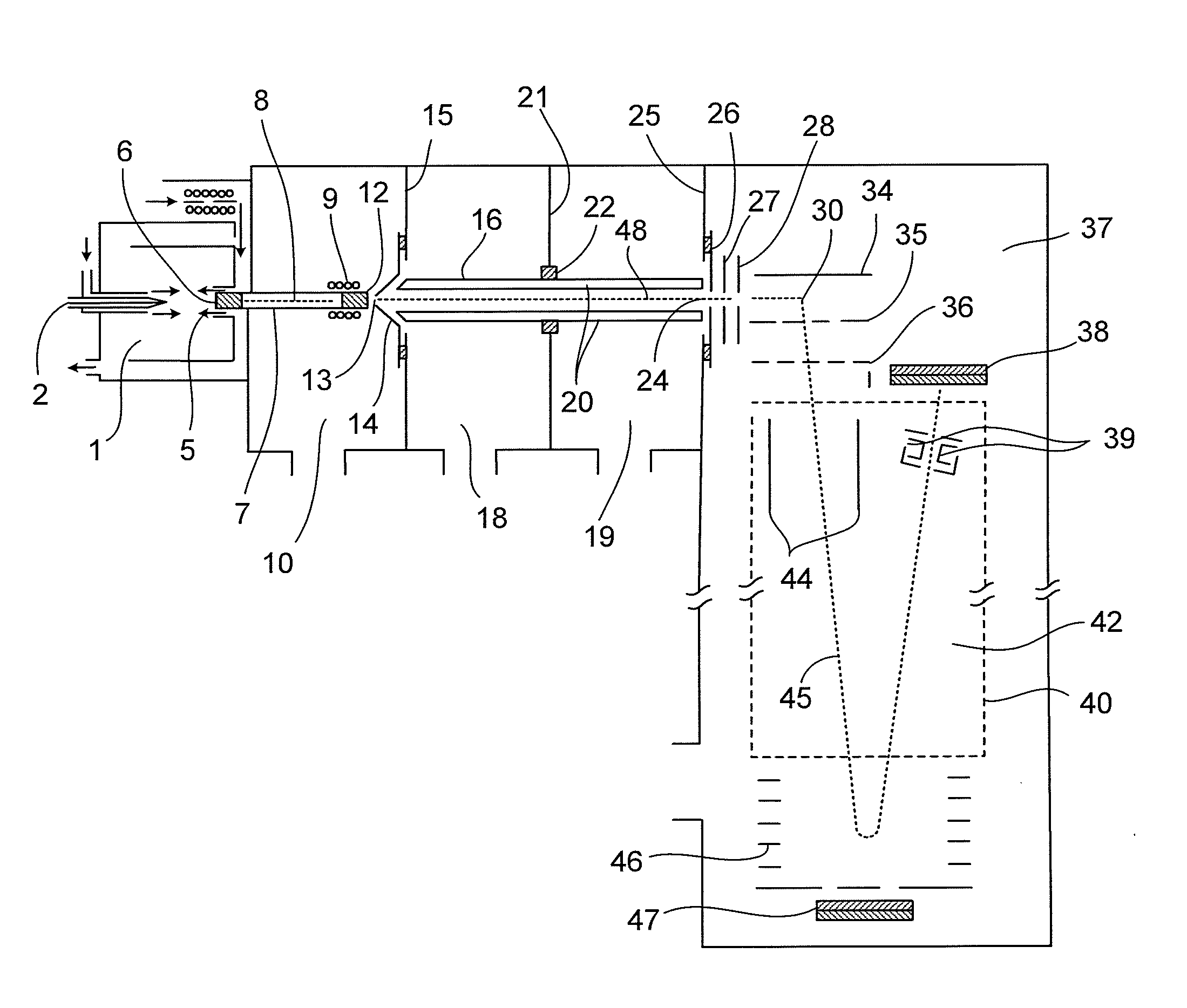

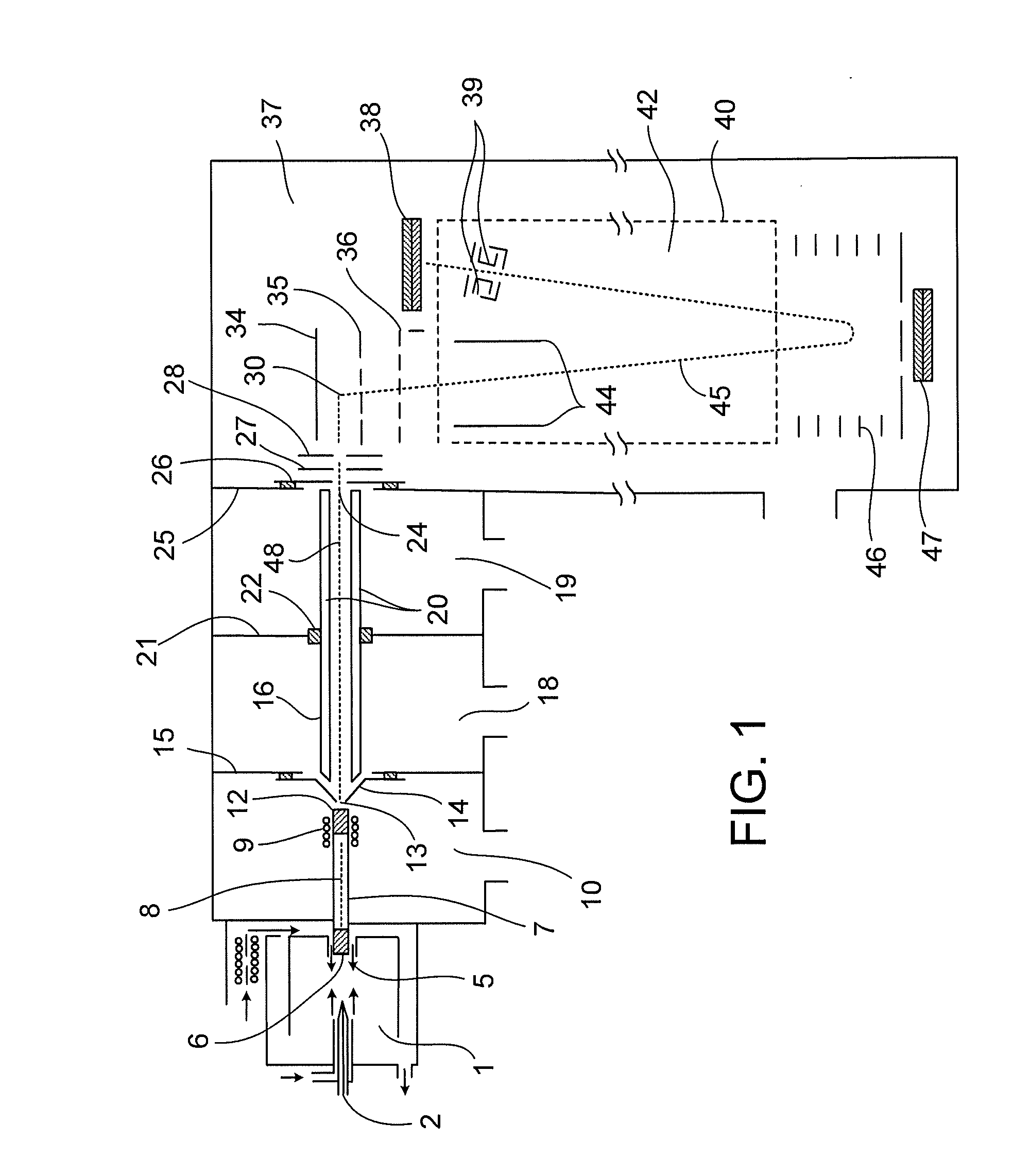

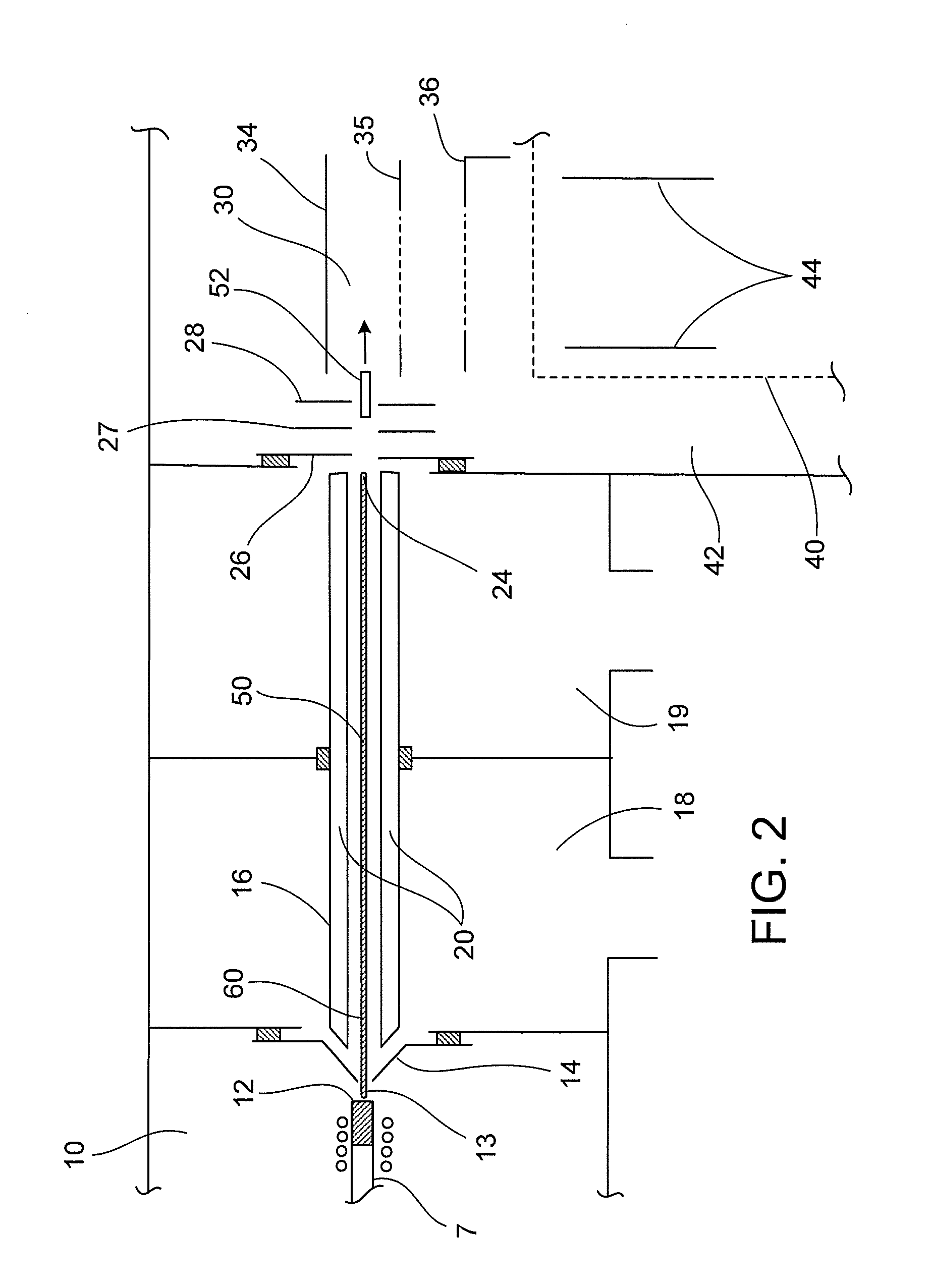

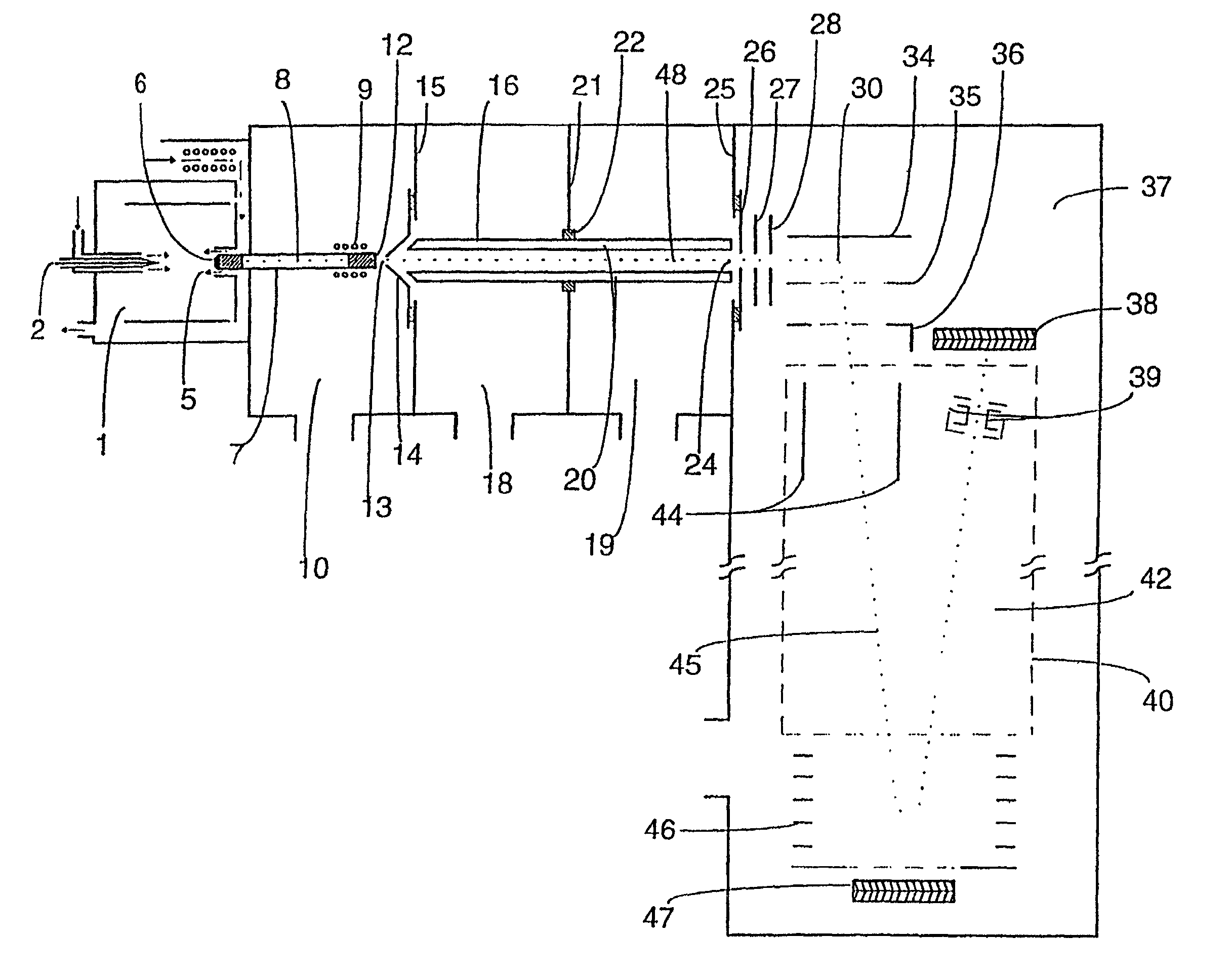

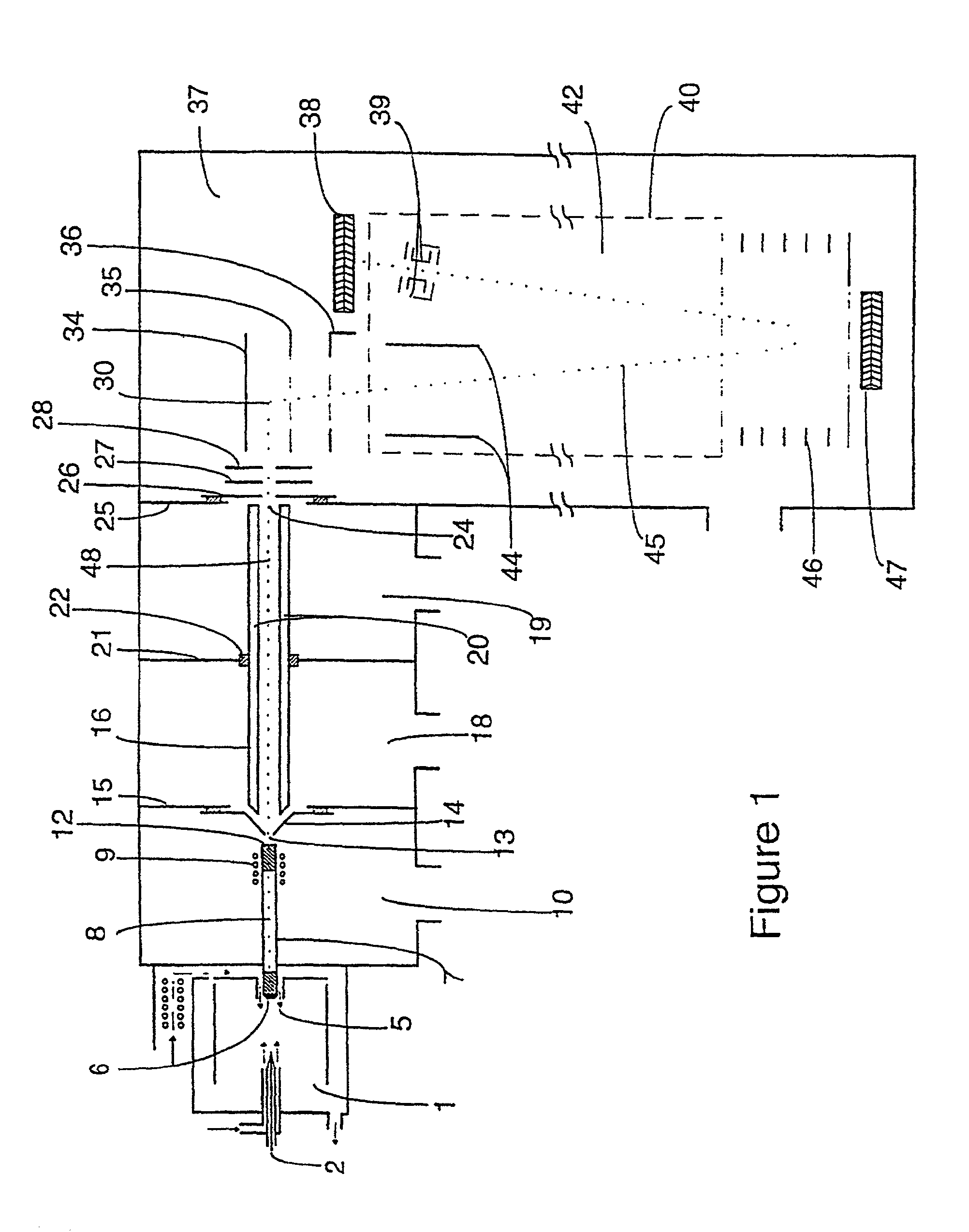

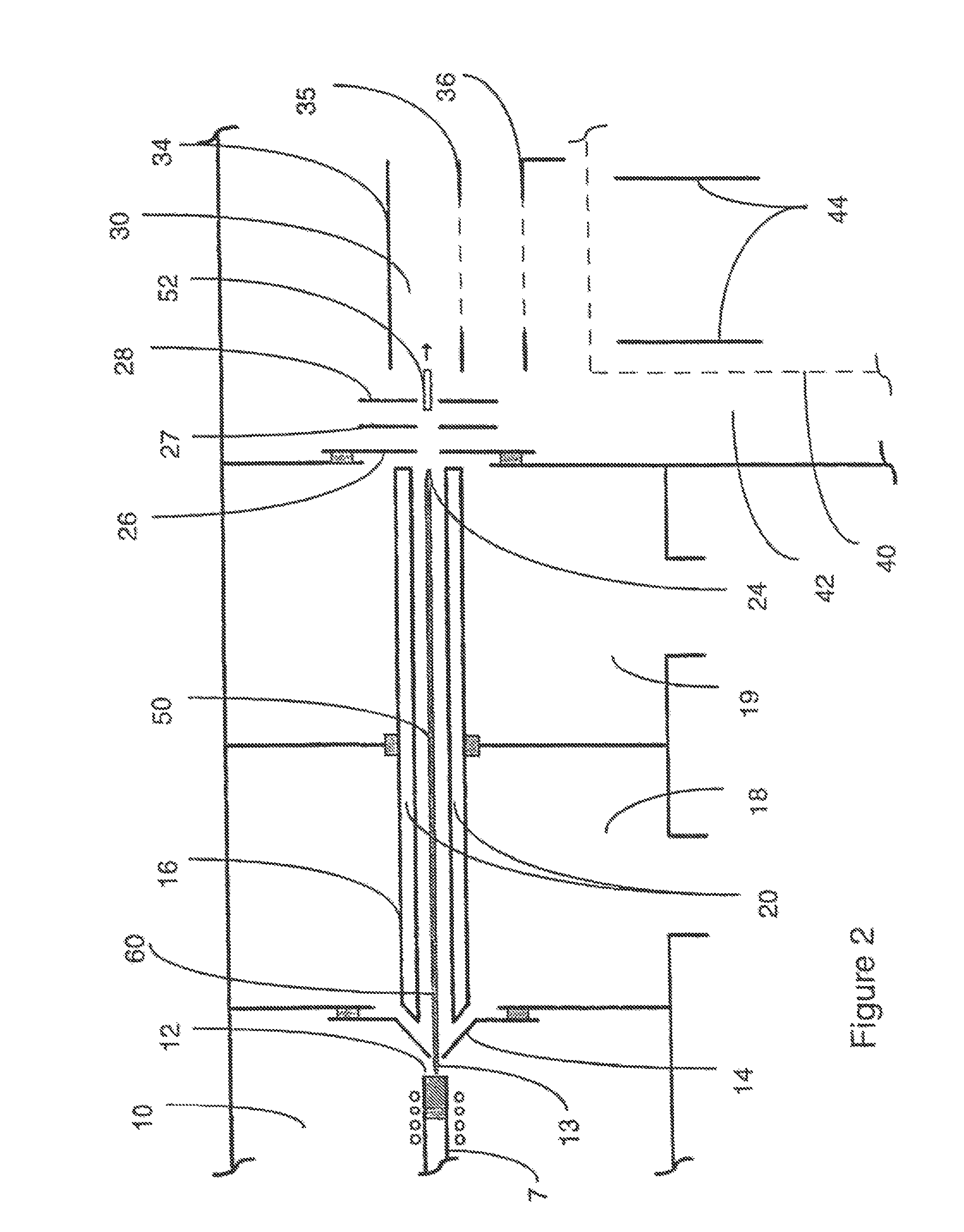

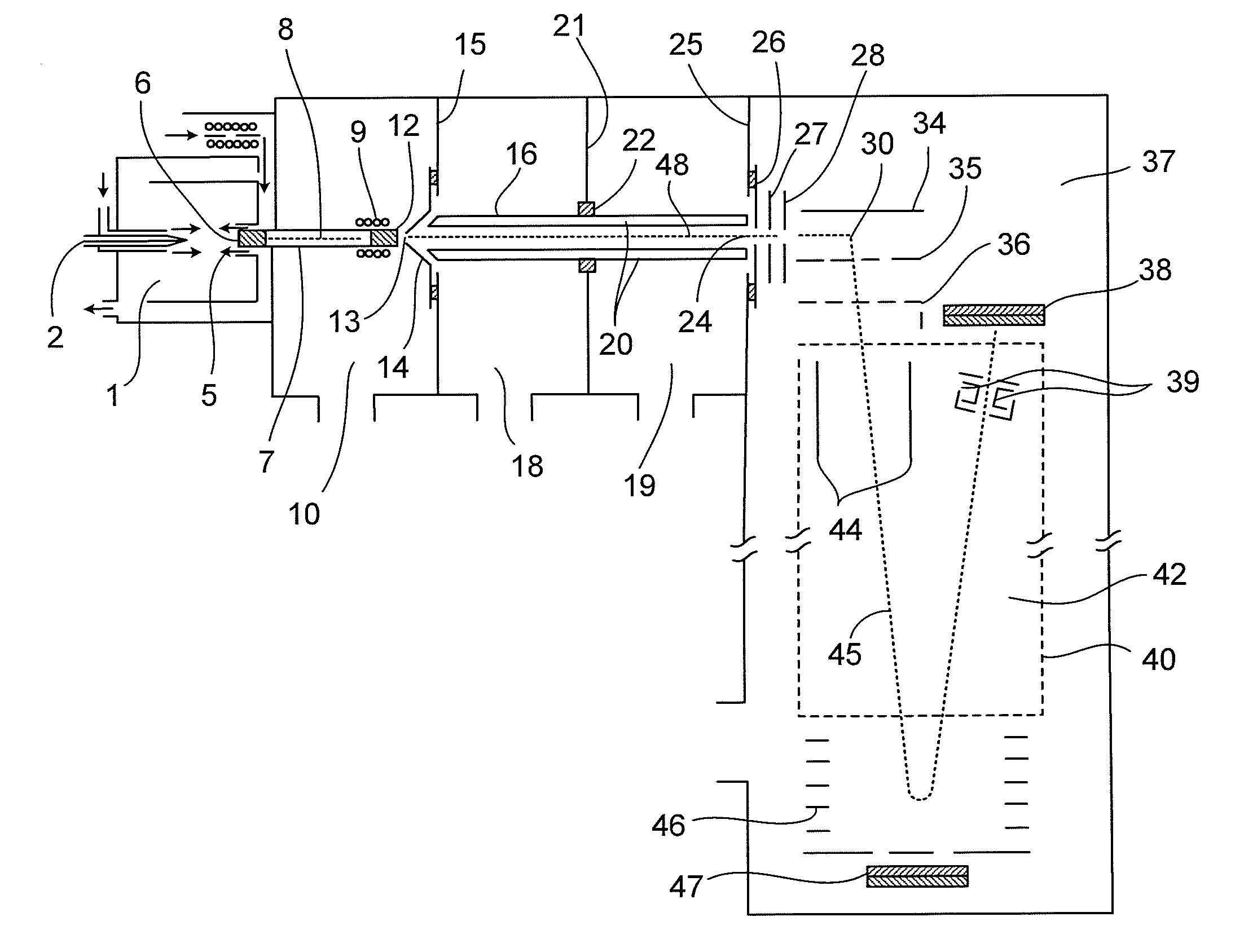

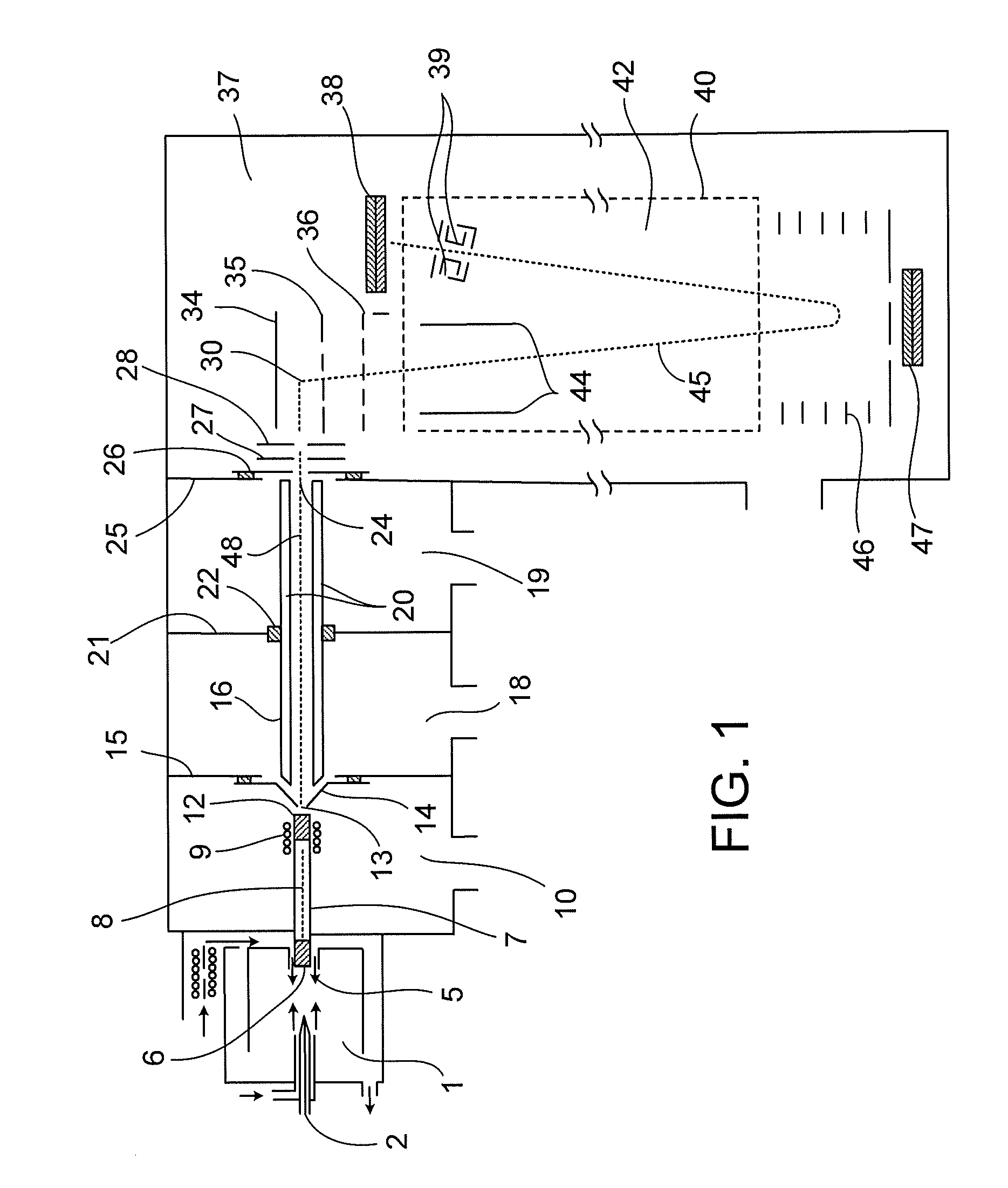

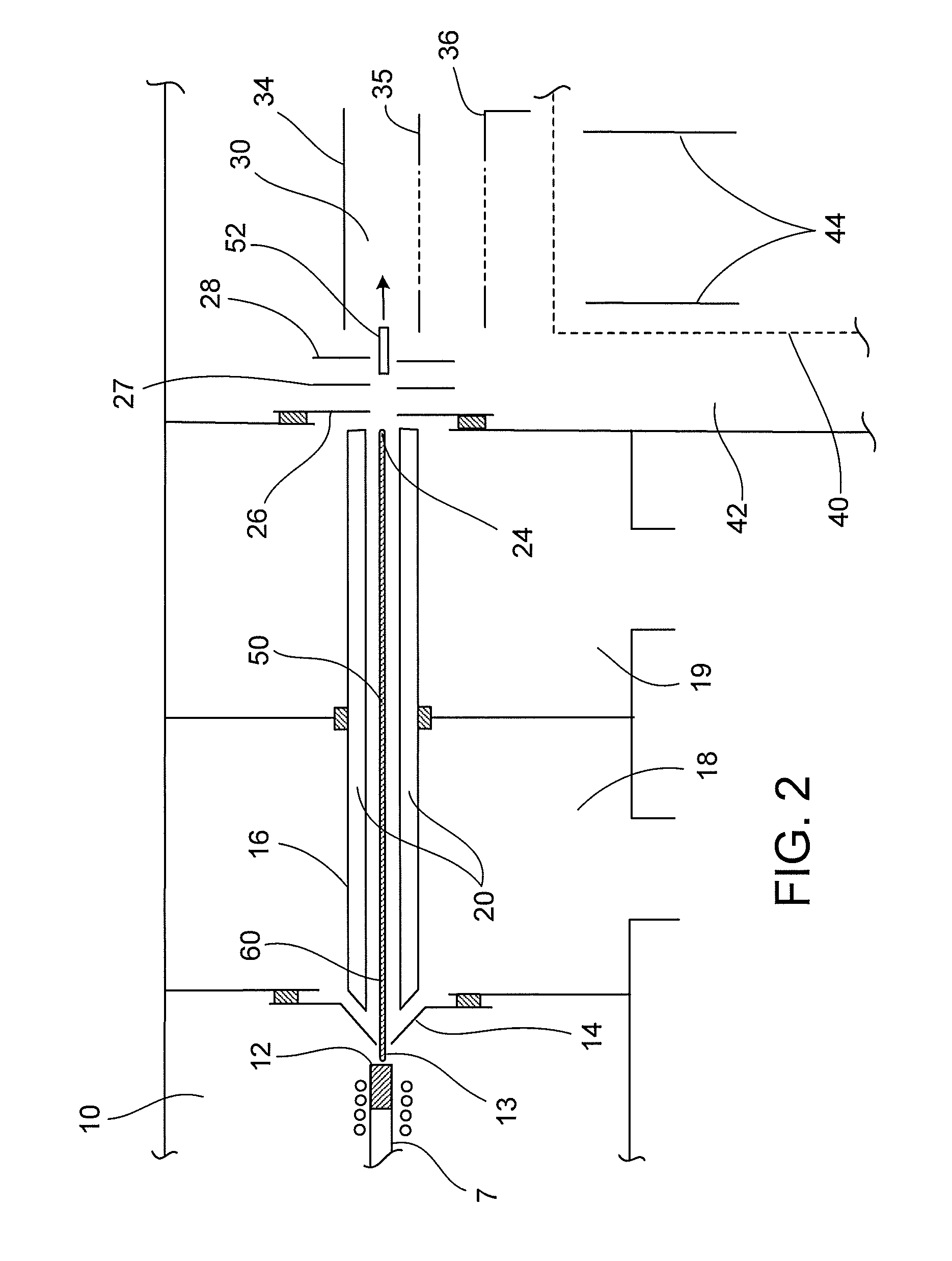

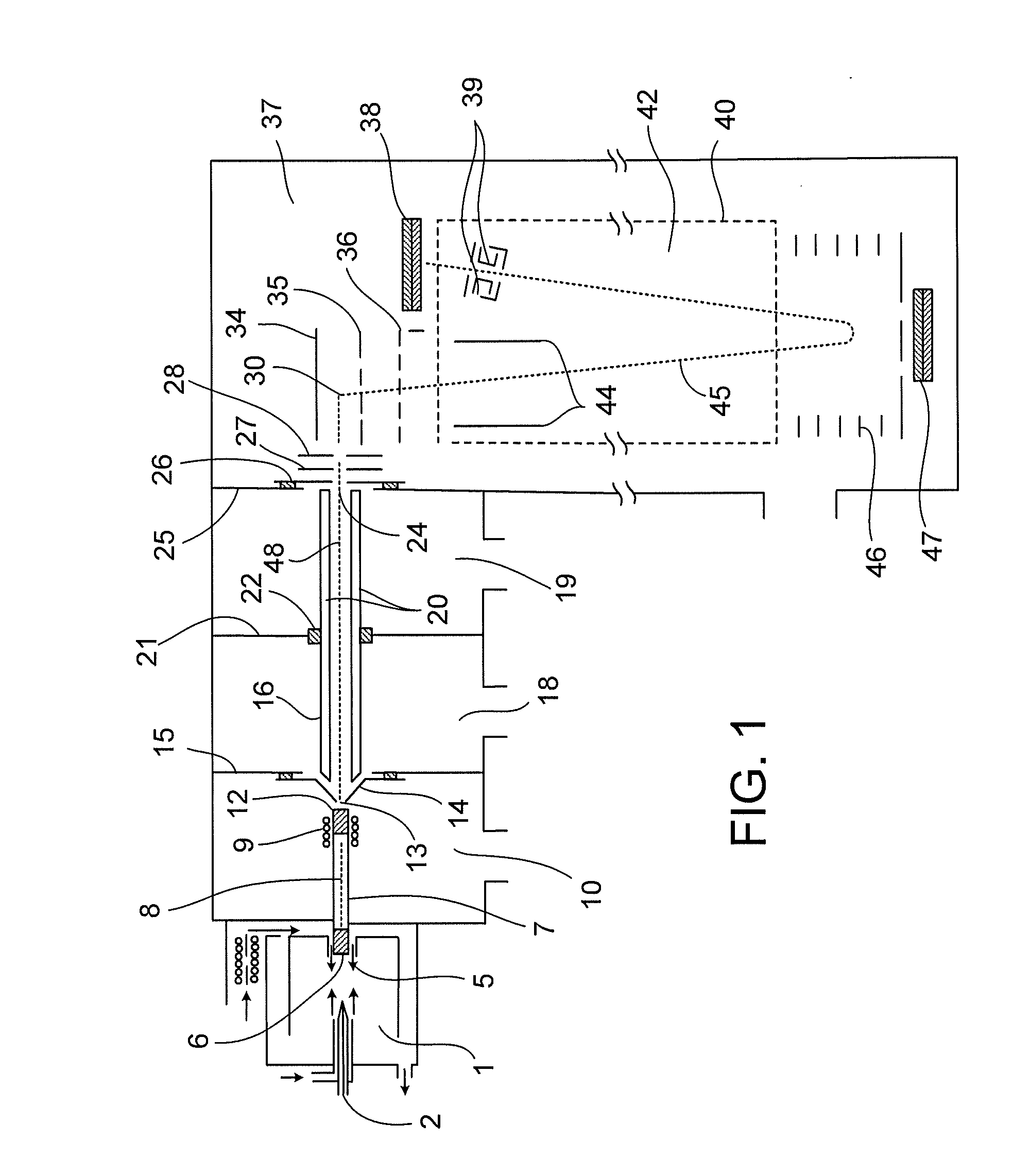

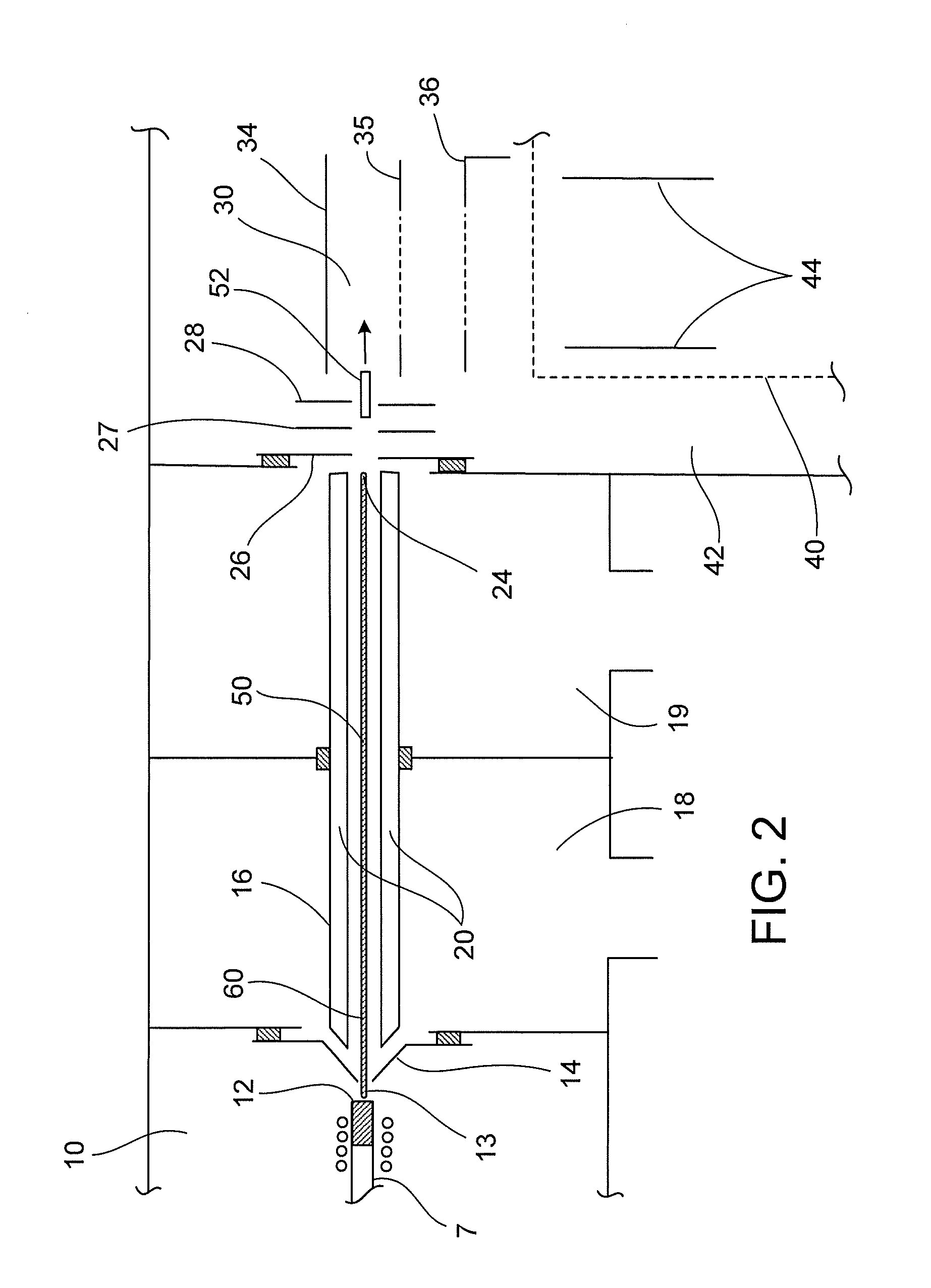

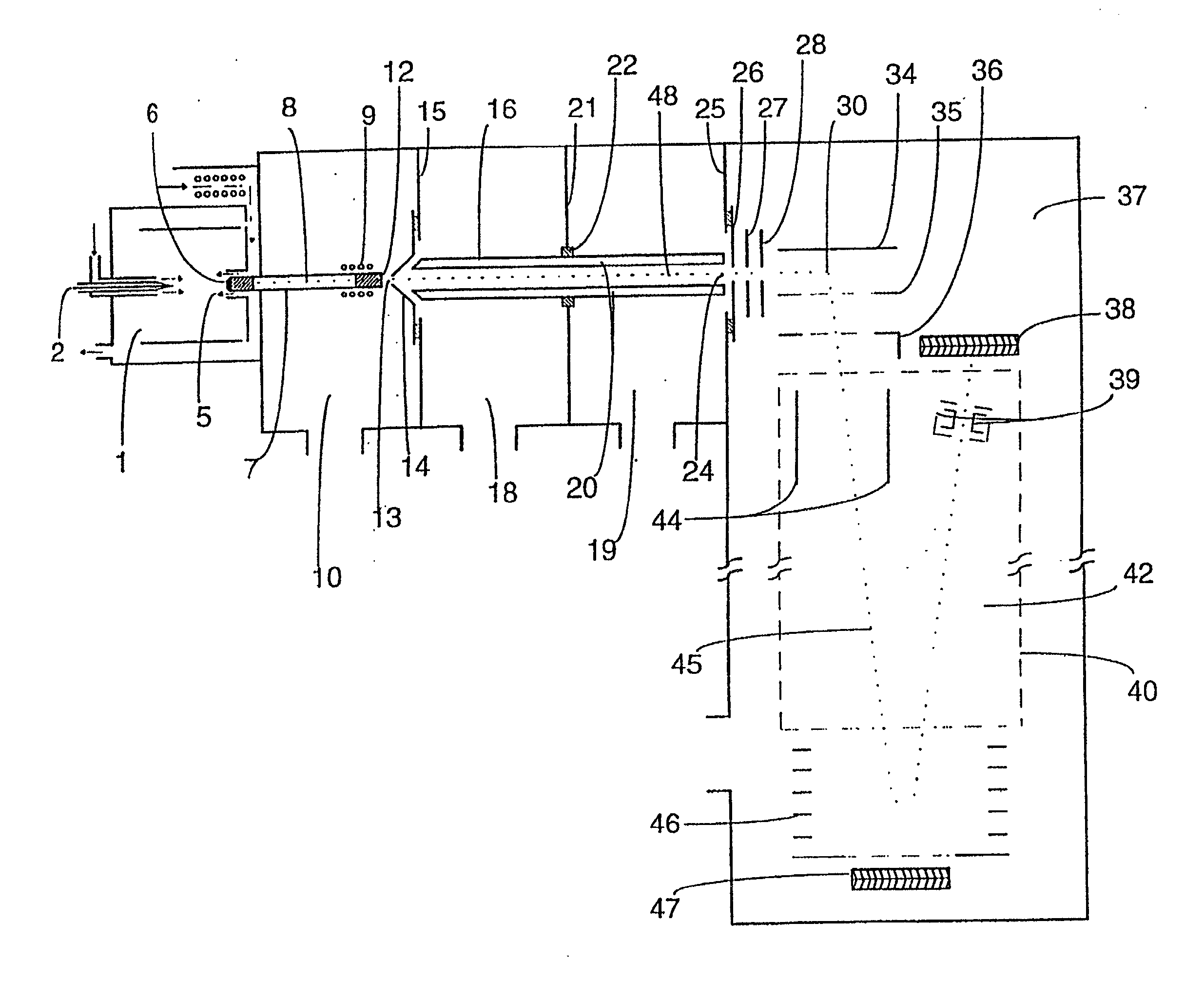

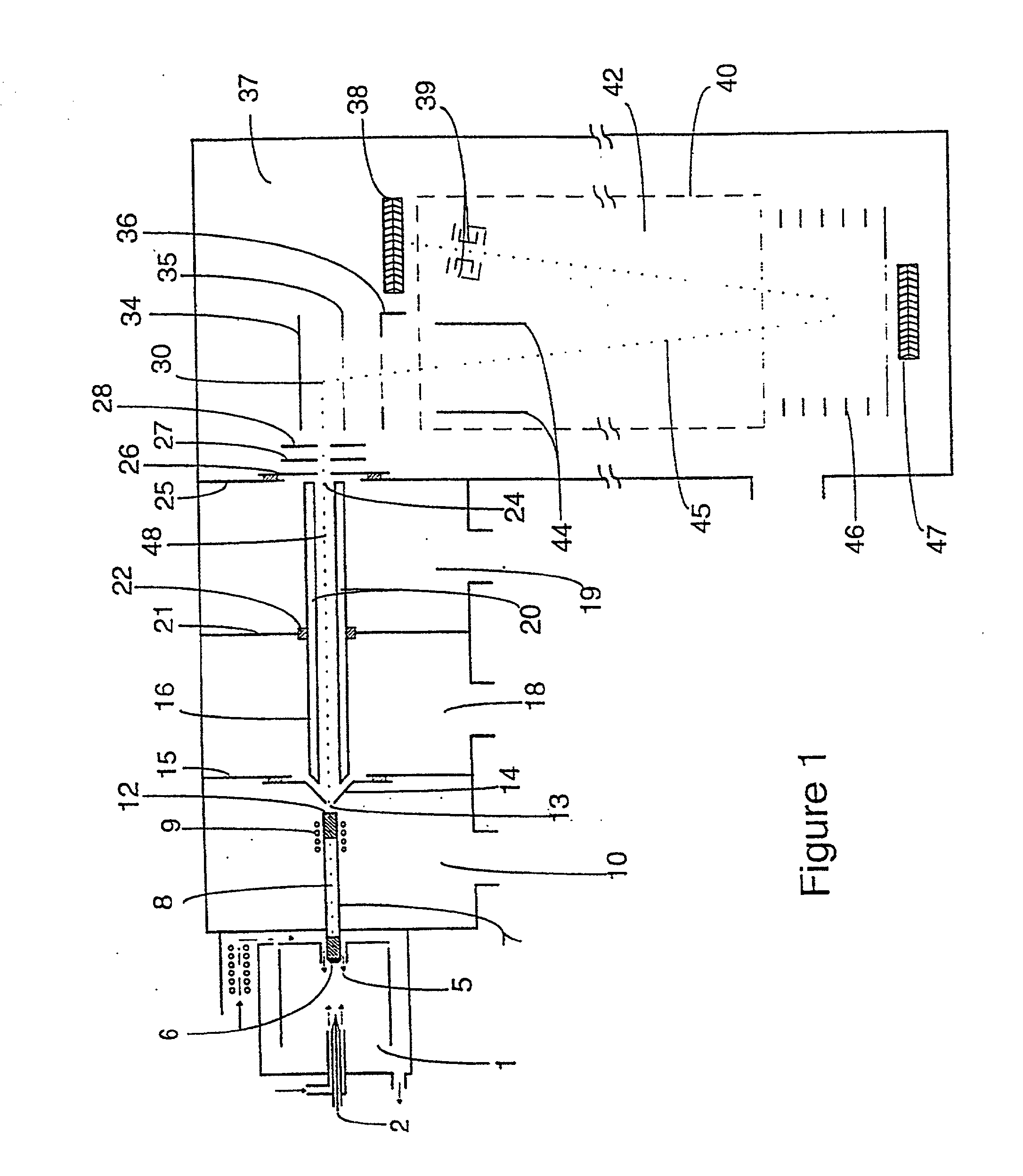

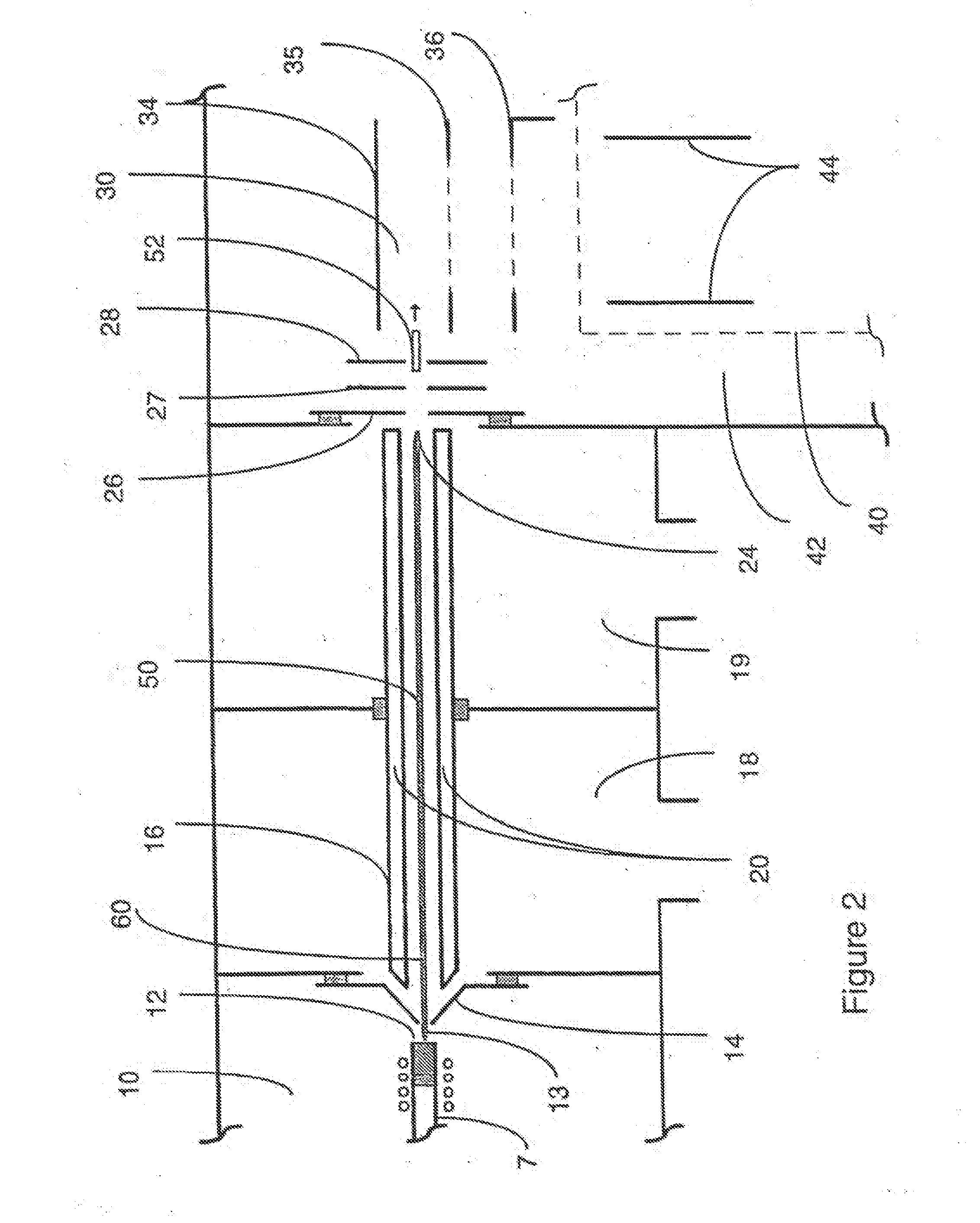

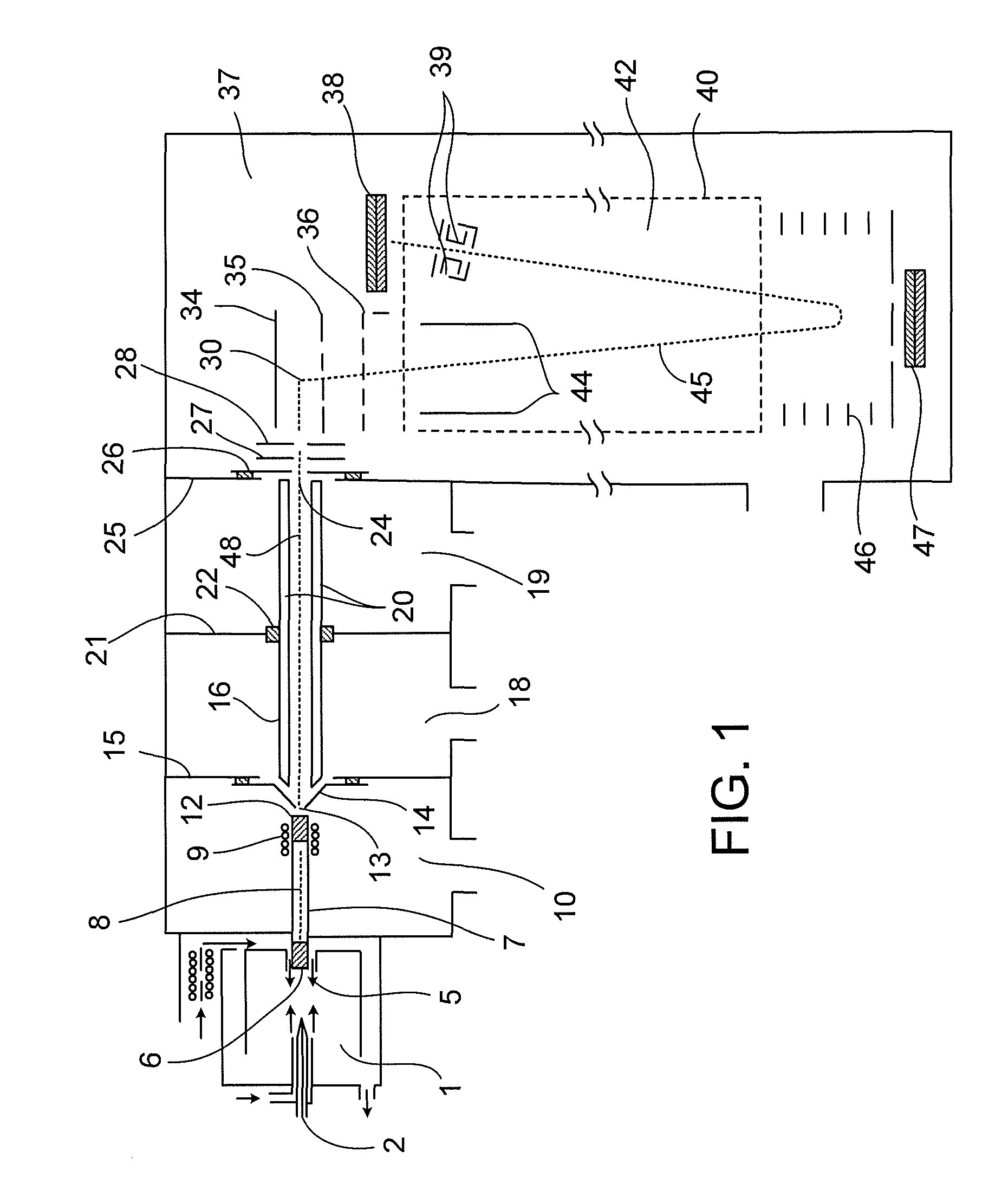

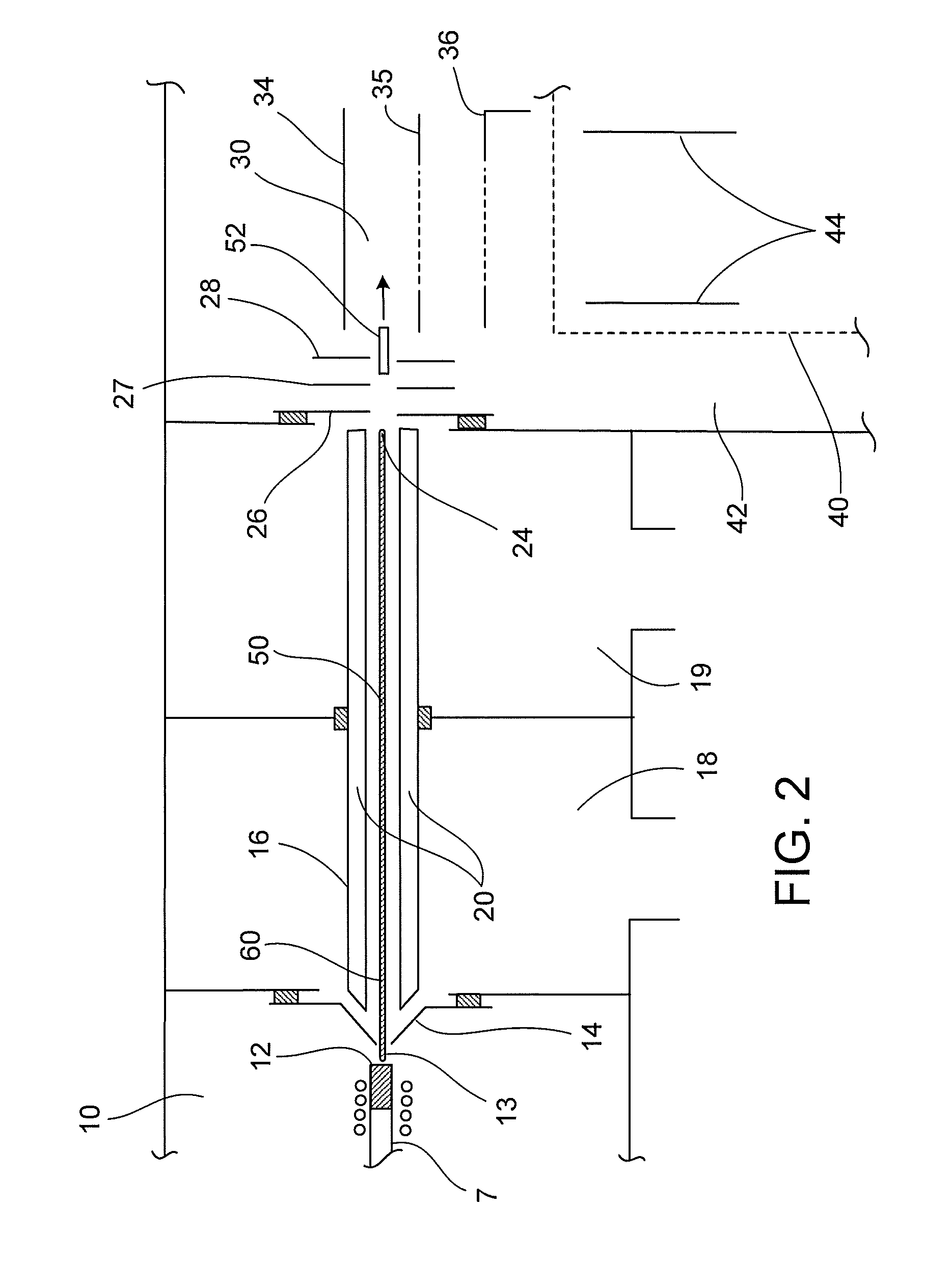

Multipole ion guide ion trap mass spectrometry with ms/msn analysis

InactiveUS20110309244A1Rapid mass analysis capabilityTrajectory stabilizationTime-of-flight spectrometersIsotope separationPopulationMass spectrum analysis

A Time-Of-Flight mass analyzer includes a multipole ion guide located in the ion flight path between the ion source and the flight tube of the Time-Of-Flight mass analyzer. In one preferred embodiment, a Time-Of-Flight (TOF) mass analyzer is configured such that a multipole ion guide is positioned in the ion path between the ion source and the ion pulsing region of the TOF mass analyzer. The multipole ion guide electronics and the ion guide entrance and exit electrostatic lenses are configured to enable the trapping or passing through of ions delivered from an atmospheric pressure ion source. The ion guide electronics can be set to select the mass to charge (m / z) range of ions which can be successfully transmitted or trapped in the ion guide. More than one set of m / z values can be selected using techniques such as notch filtering with resonant frequency ion ejection of unwanted m / z values. All or a portion of the ions with stable ion guide trajectories in transmission or trapping mode can then undergo Collisional Induced Dissociation (CID) using one of at least three techniques. During the ion fragmentation step the multipole ion guide AC and DC electric potentials are set to transmit or trap all or a portion of the fragment ions produced by the CID process. All or a portion of the parent and fragment ion population are delivered from the multipole ion guide to the pulsing region of Time-OF-Flight mass analyzer for mass analysis. After the first ion fragmentation step, the multipole ion guide AC and DC electric potentials can again be set to select a narrow m / z range to clear the ion guide in trapping mode of all but a selected set of fragment ions. The m / z selection and ion fragmentation step can be repeated a number of times with mass analysis occurring at the end of all the MS / MSn steps or at various times during the MS / MSn stepwise process. A technique is also described where the normally stepwise MS / MSn analysis function can be merged into a single step, increasing the effective duty cycle. The multipole ion guide used for ion transmission, trapping and fragmentation can reside in one vacuum pumping stage or can extend continuously into more than one vacuum pumping stage.

Owner:PERKINELMER HEALTH SCIENCES INC

Rubber cutting robot

ActiveCN110696008AImprove accuracyExtend your lifeForestryManipulatorControl systemControl engineering

The invention relates to a rubber cutting robot which comprises a clamping mechanism, a cutting mechanism, a moving mechanism, a measuring and limiting module and an existing control system. The rubber cutting robot is fixed to a rubber tree through the clamping mechanism. The moving mechanism and the measuring and limiting module are arranged on the clamping mechanism and both connected with theexisting control system. The measuring and limiting module transmits a received signal into the existing control system, and the existing control system controls the moving mechanism to act accordingto the received measurement signal. The cutting mechanism is arranged on the moving mechanism and driven by the moving mechanism to do spiral movements on the clamping mechanism. The cutting mechanismis connected with the existing control system and controlled by the existing control system to work. The rubber cutting accuracy can be improved, and the waste of rubber liquid and the damage to rubber latex vessel tissue caused by artificial operation errors are avoided, and the repeated cutting rate is effectively increased.

Owner:BEIJING INFORMATION SCI & TECH UNIV

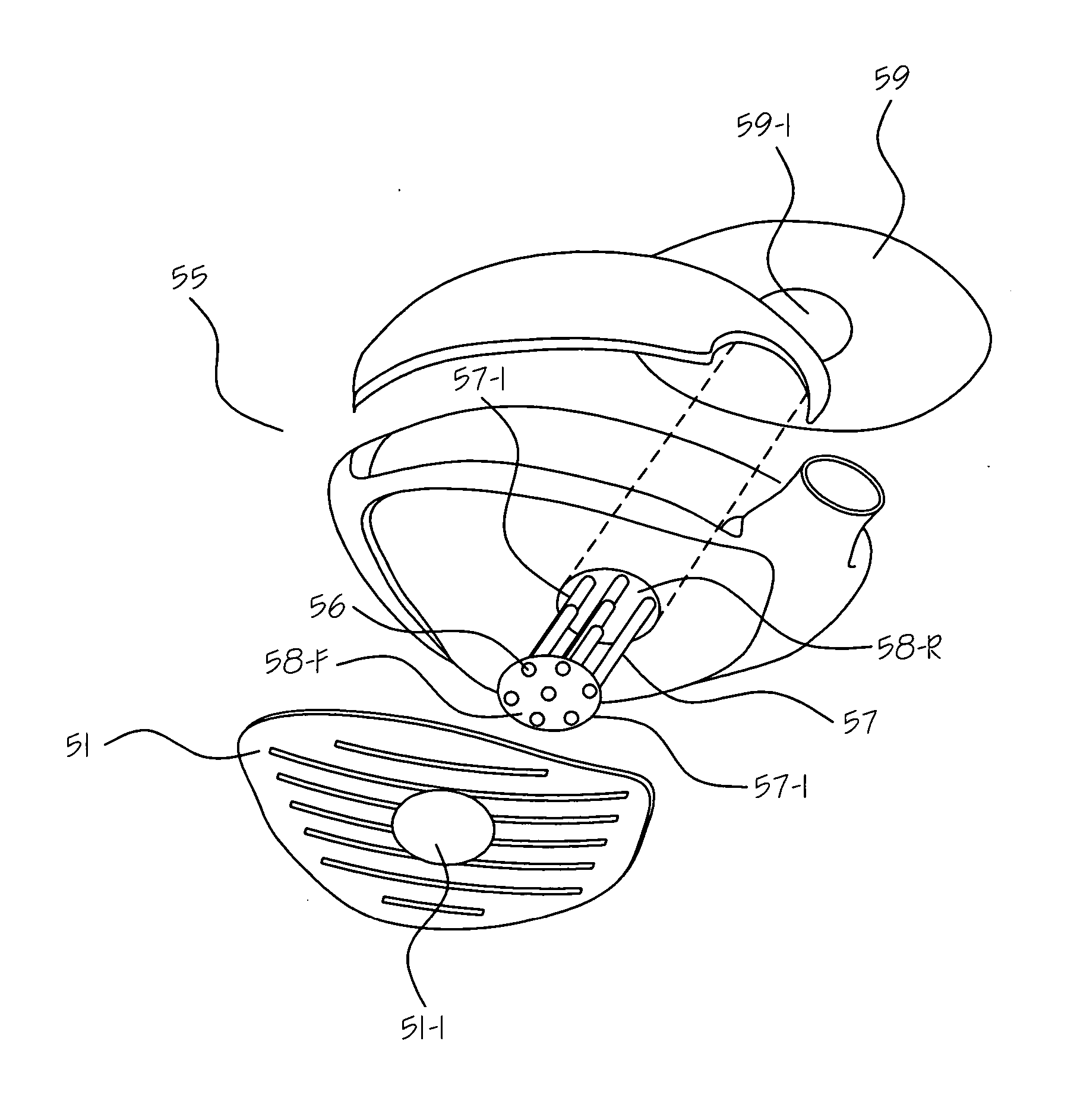

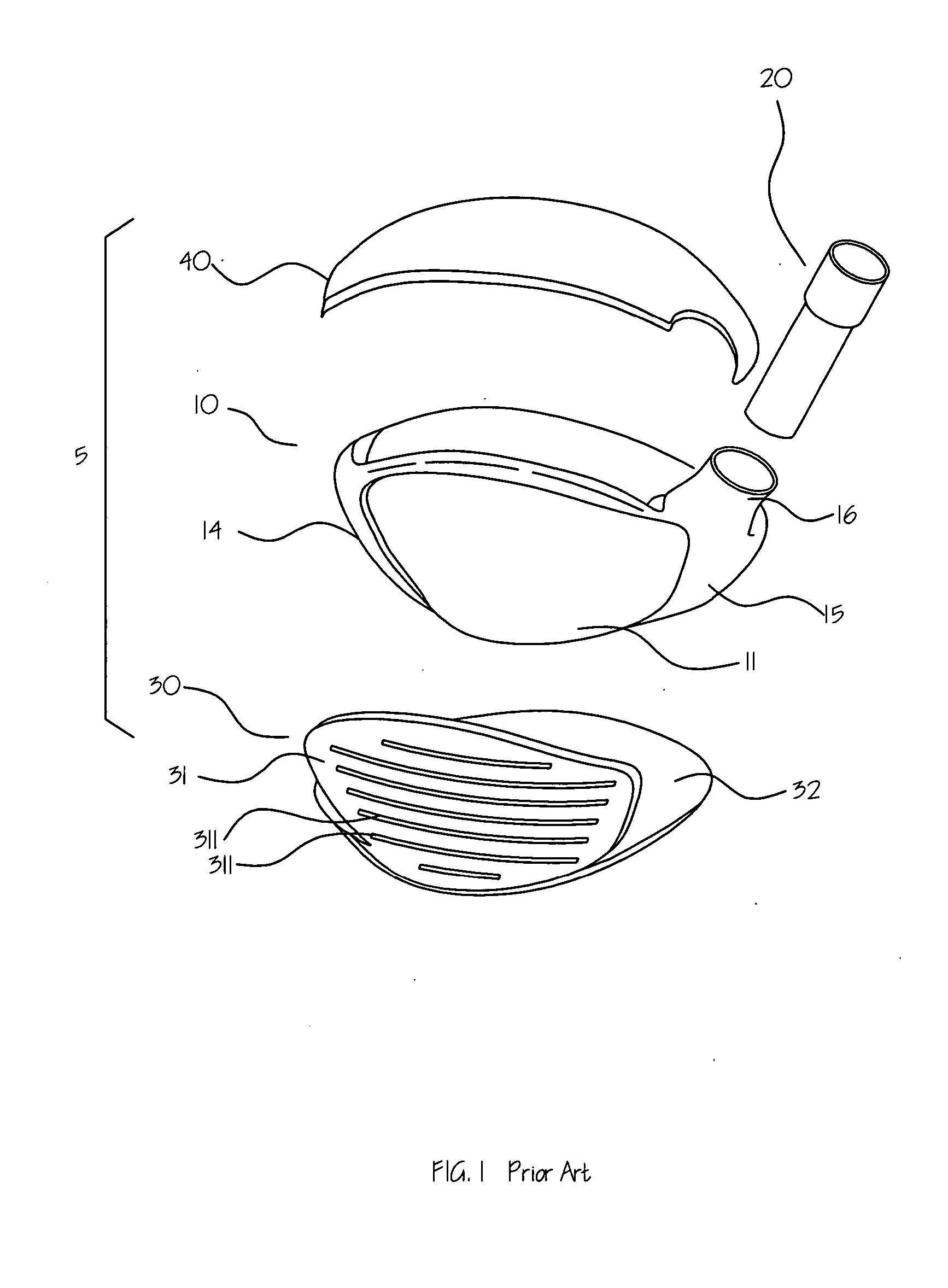

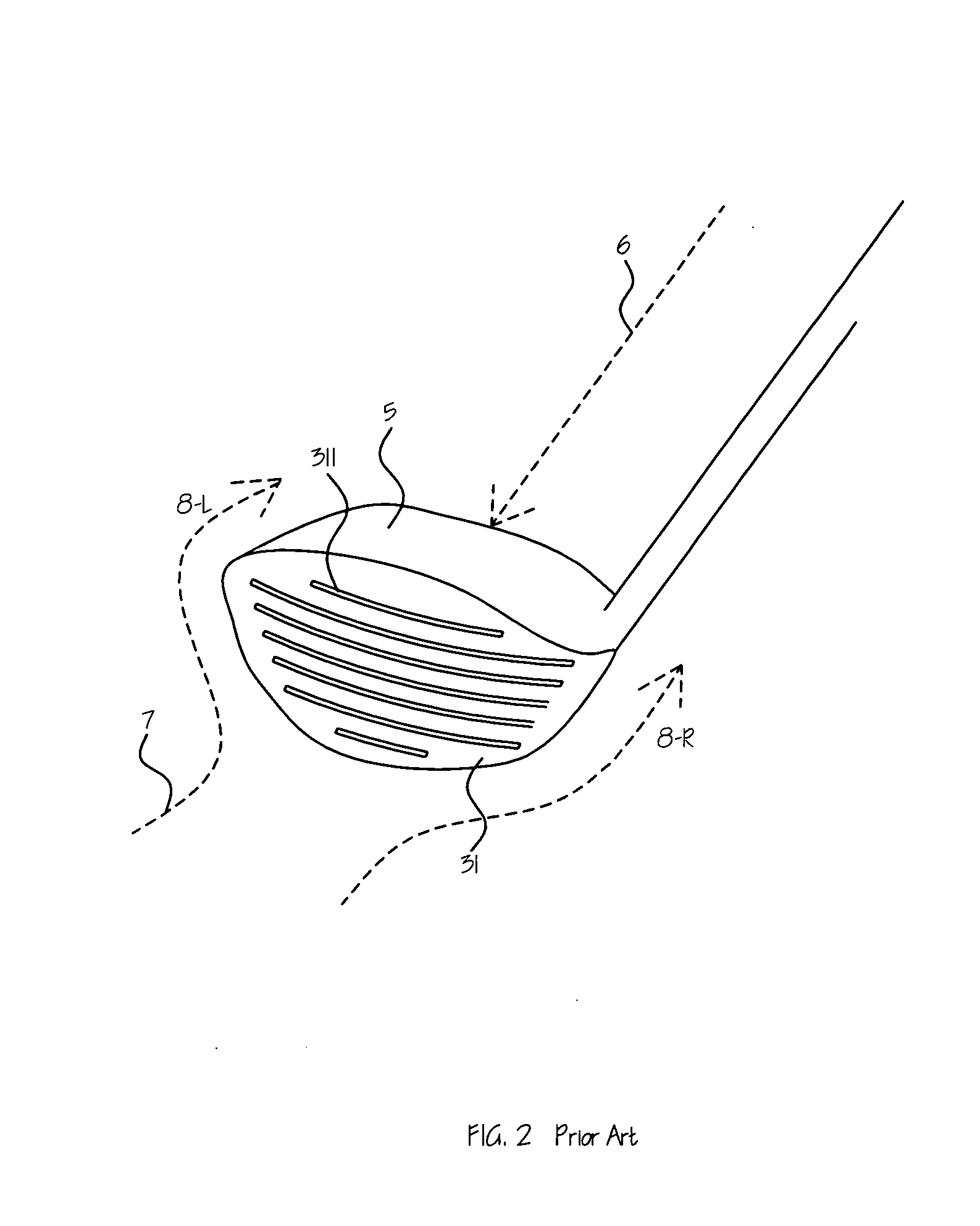

Trajectory stability increased golf clubs with pluralities of holes

InactiveUS20060281580A1Improve stabilityStable swing trajectoryBathroom accessoriesGolf clubsSpeed wobbleEngineering

A golf club head is provided, which has a number of holes developed on the head by installing a number of metal tubes of 3 mm diameter between the front face and rear face of the head. Another embodiment of the current application is a golf iron having a number of holes on the head. Air stream through the holes stabilizes the trajectory of the golf clubs at high speed of swing.

Owner:KIM YEOUNG HO +1

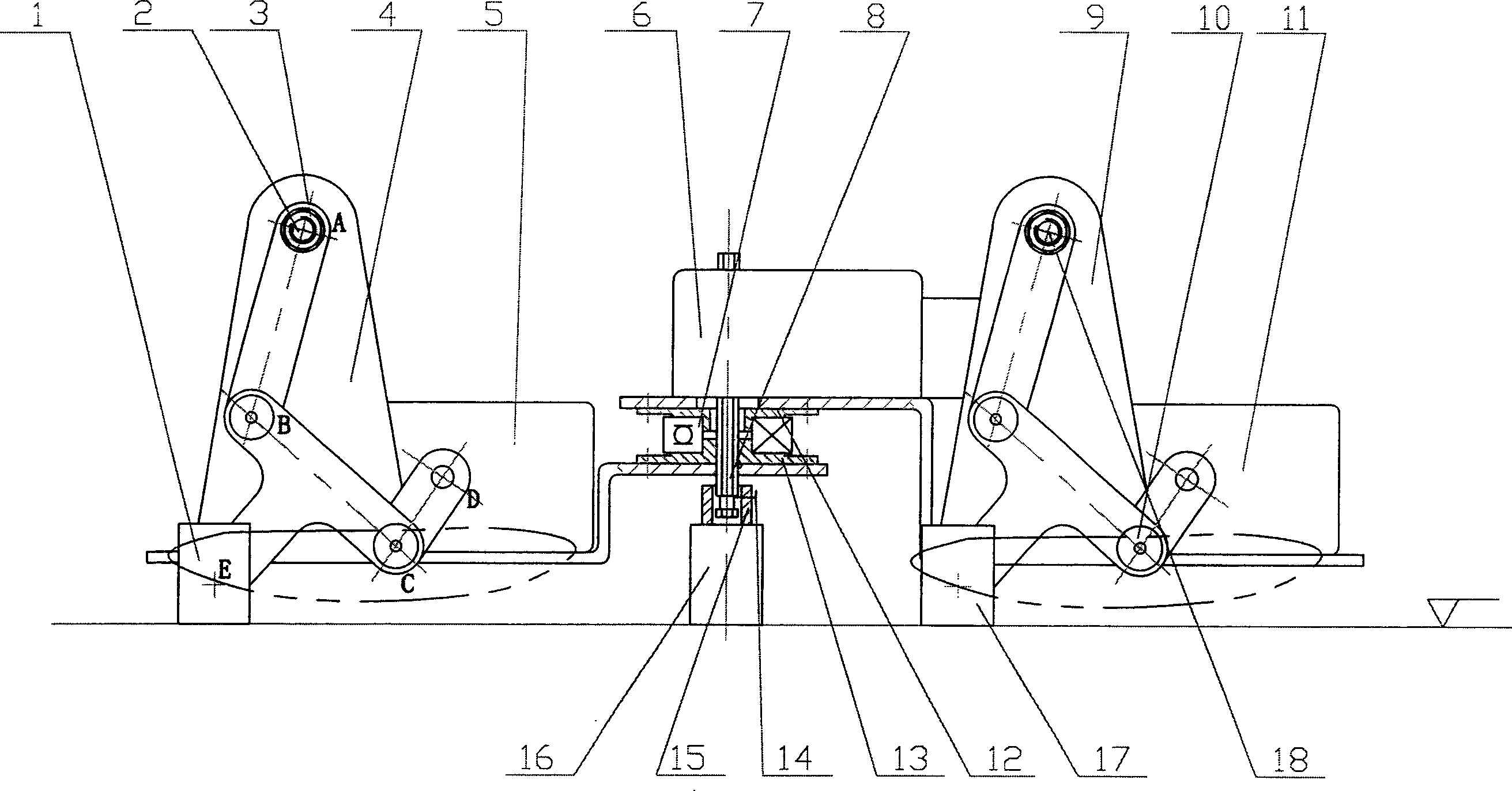

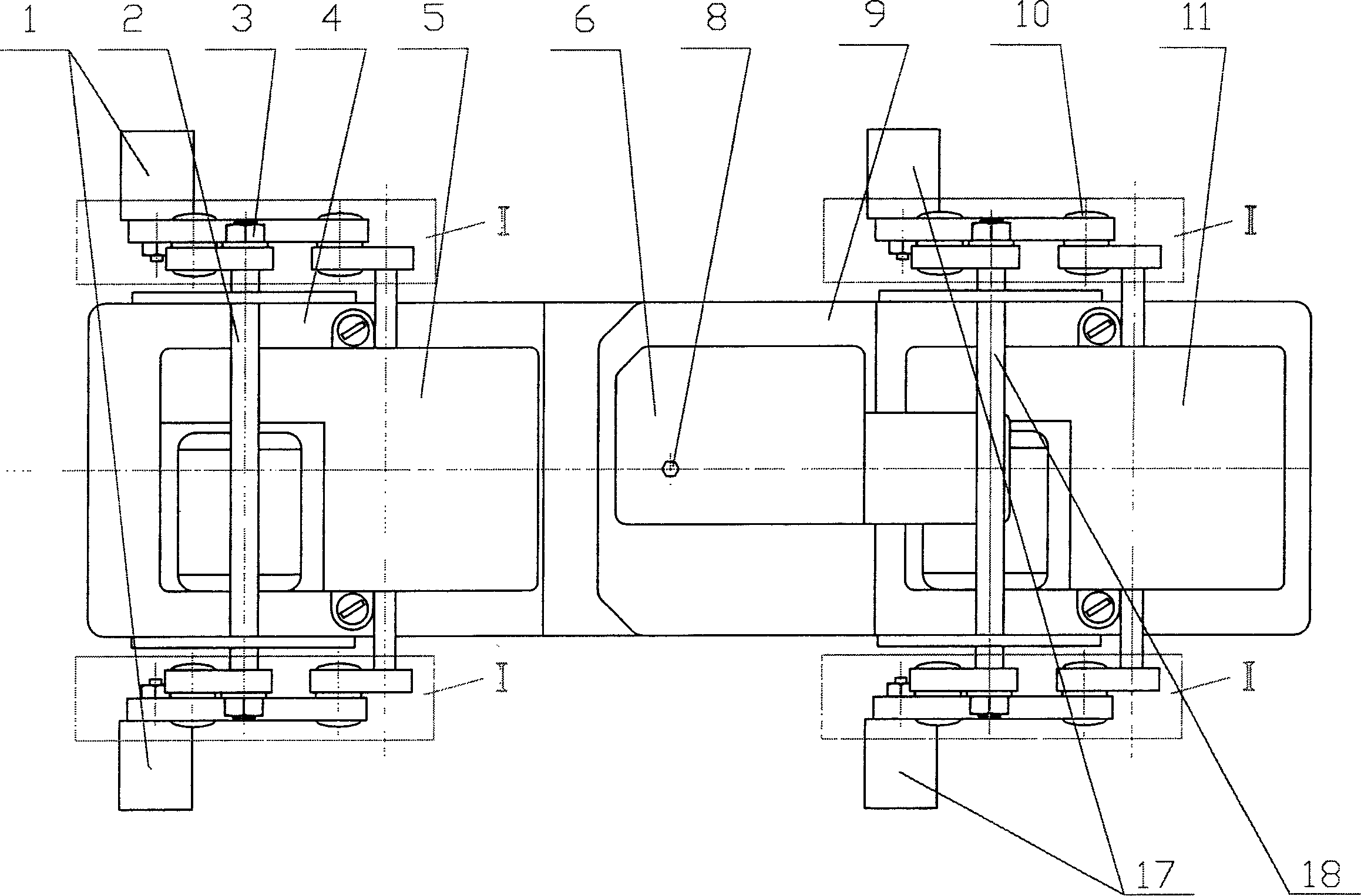

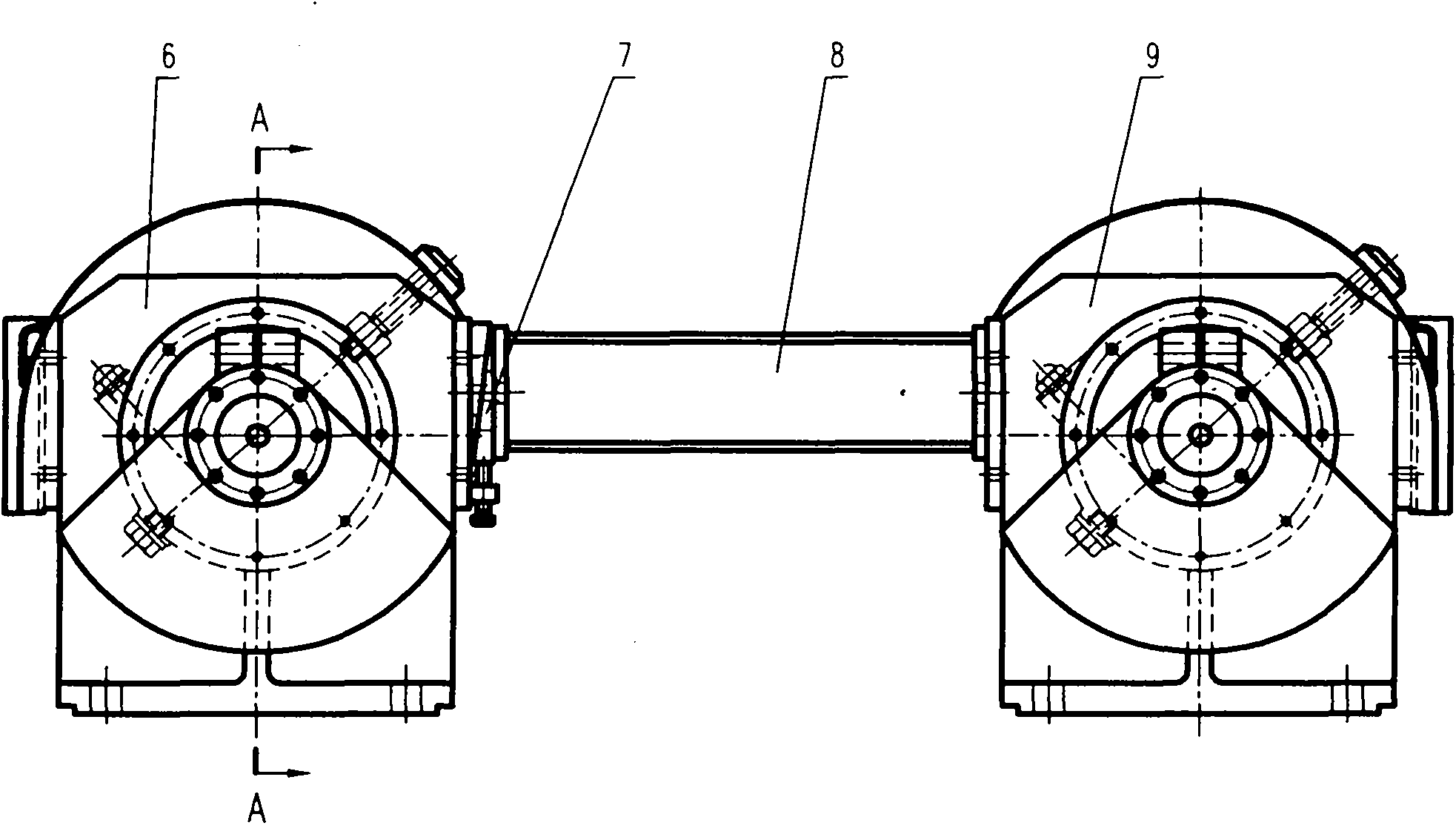

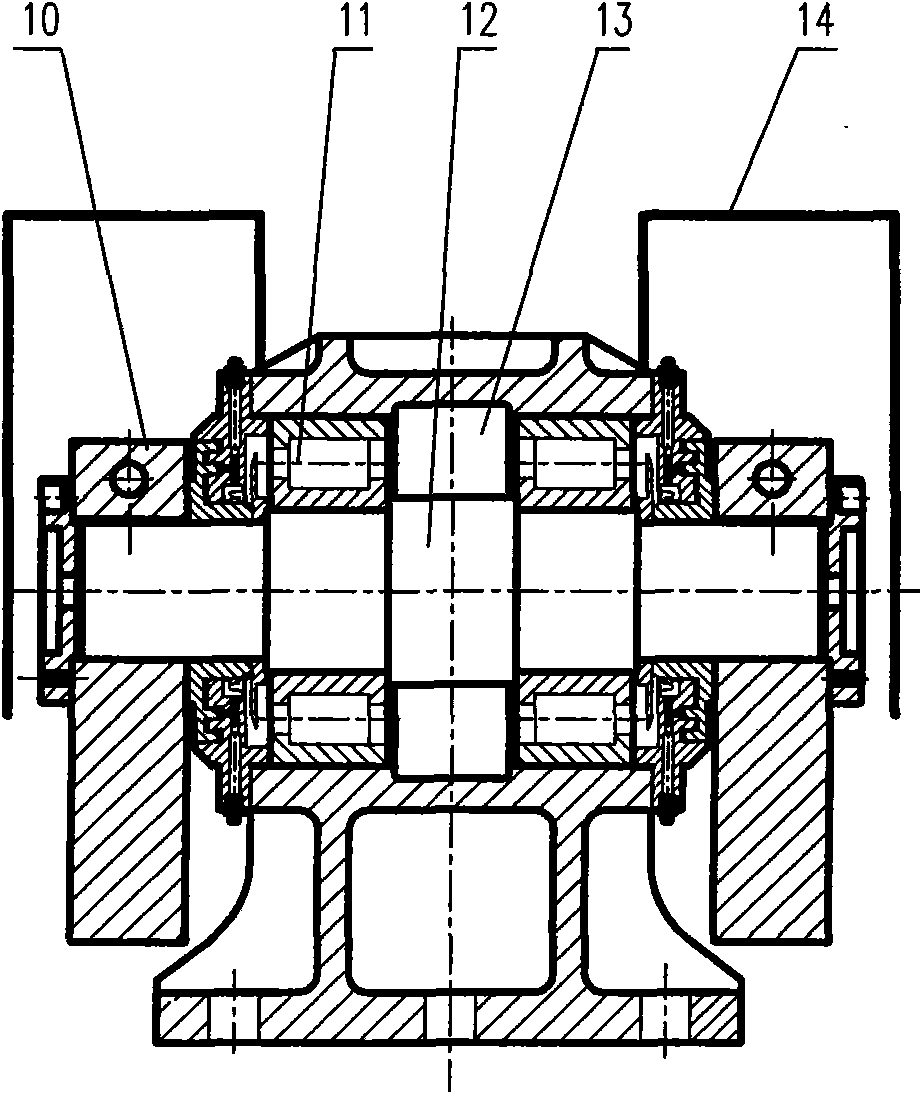

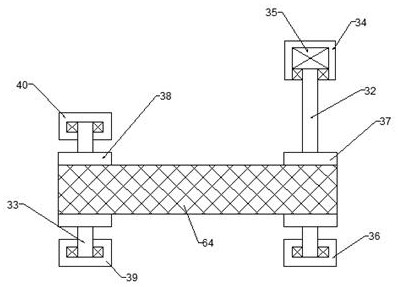

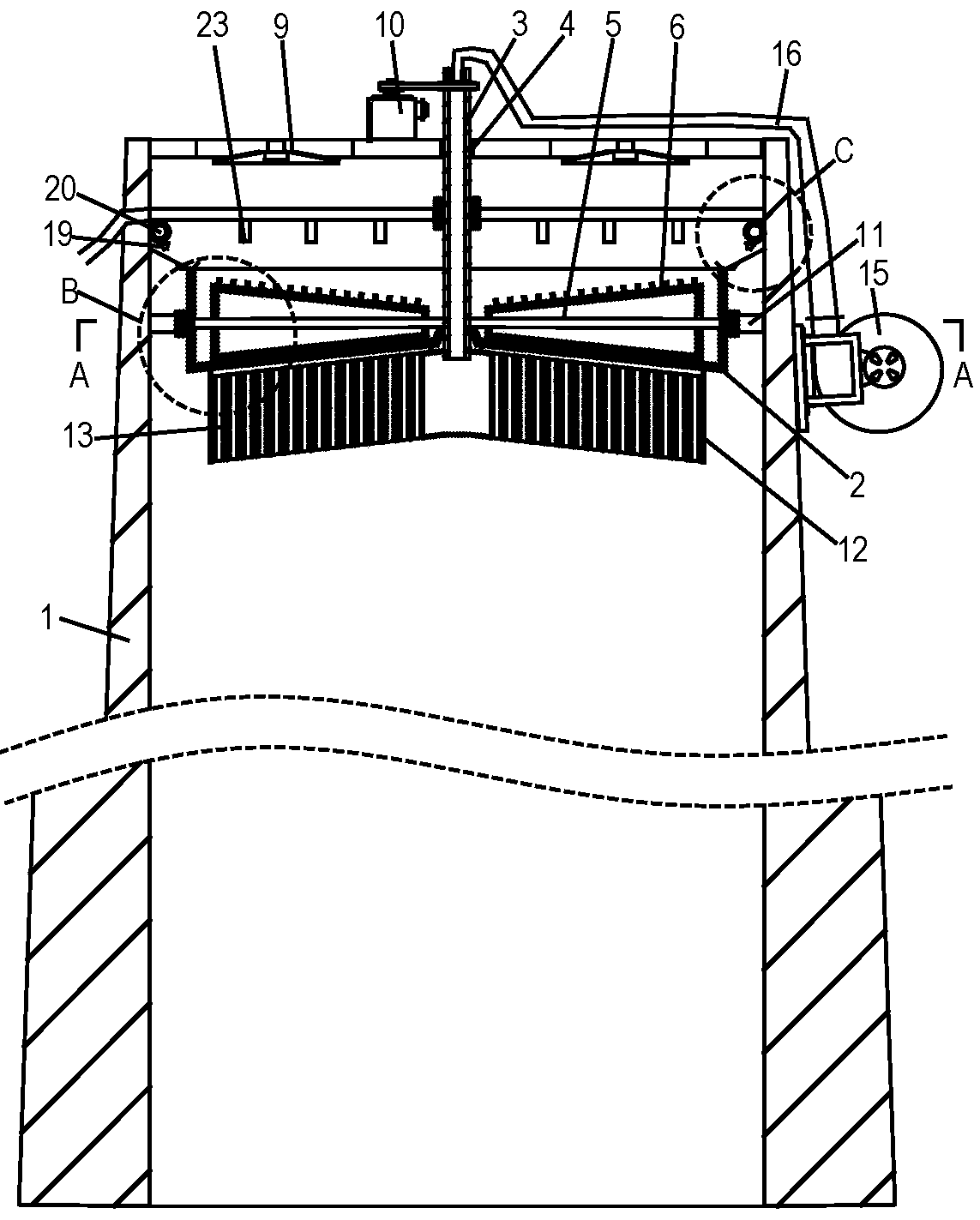

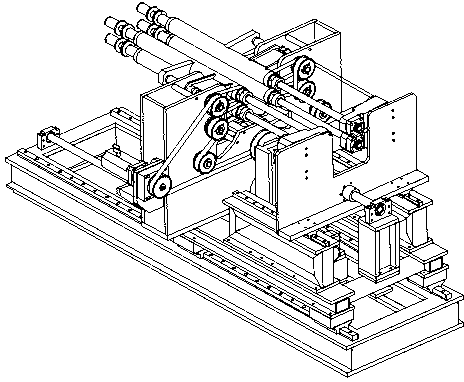

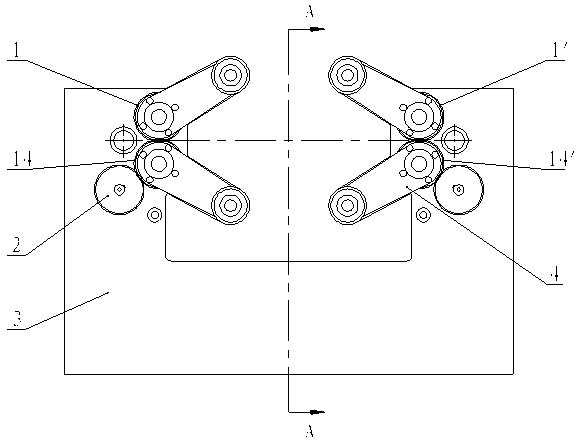

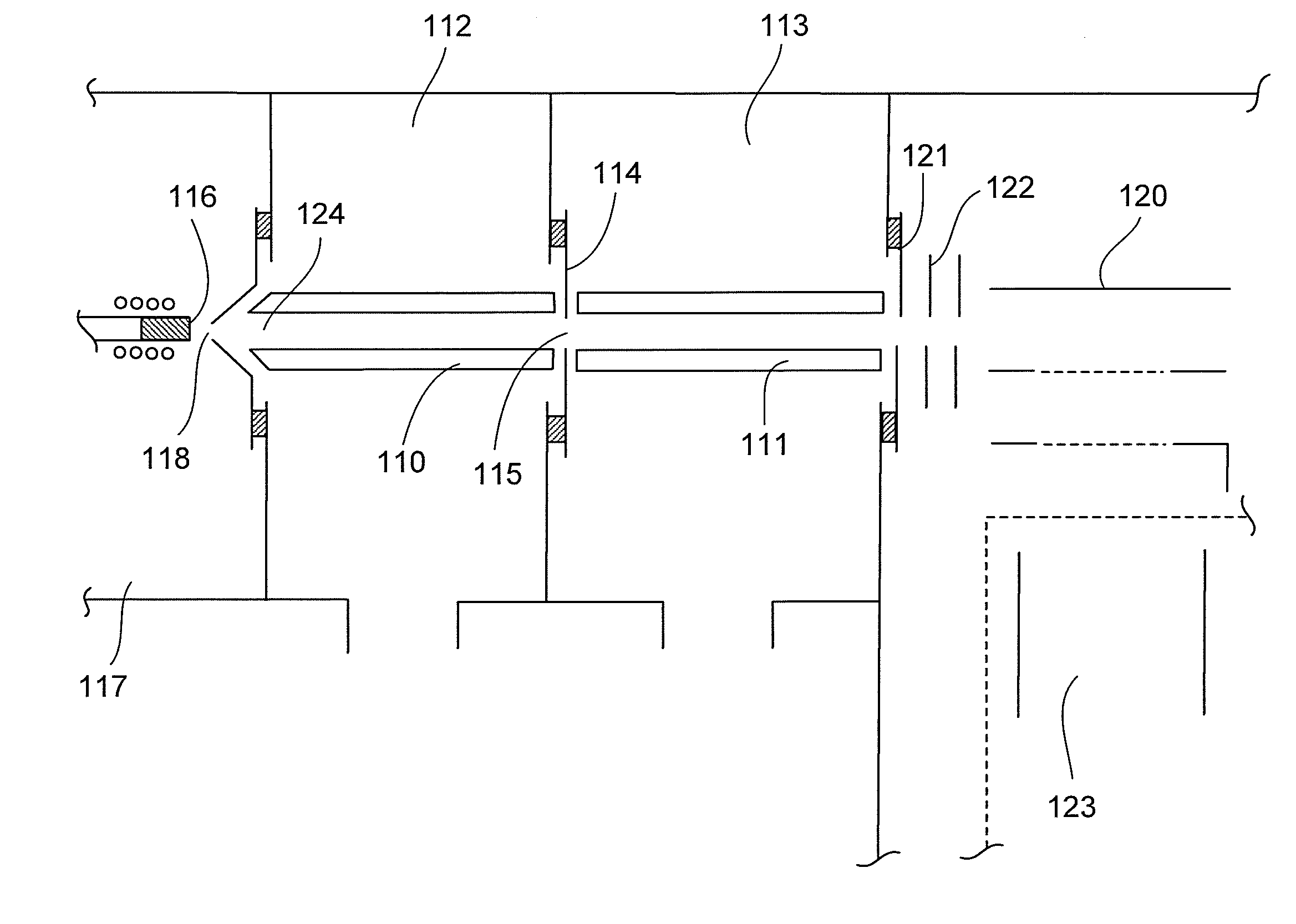

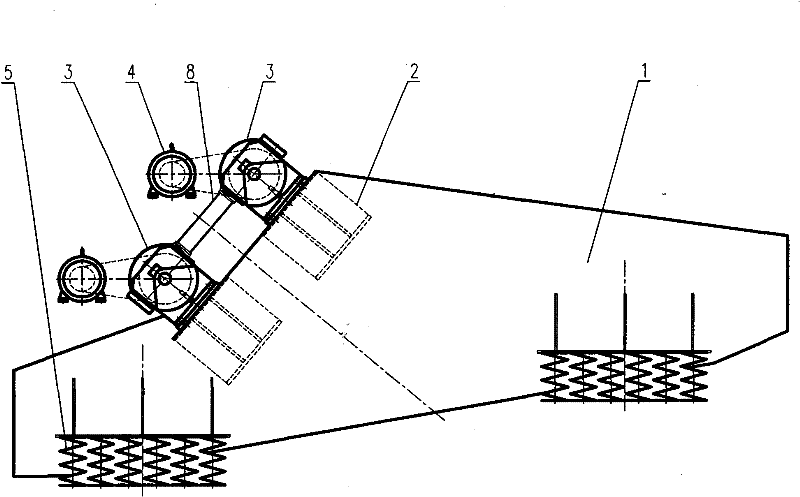

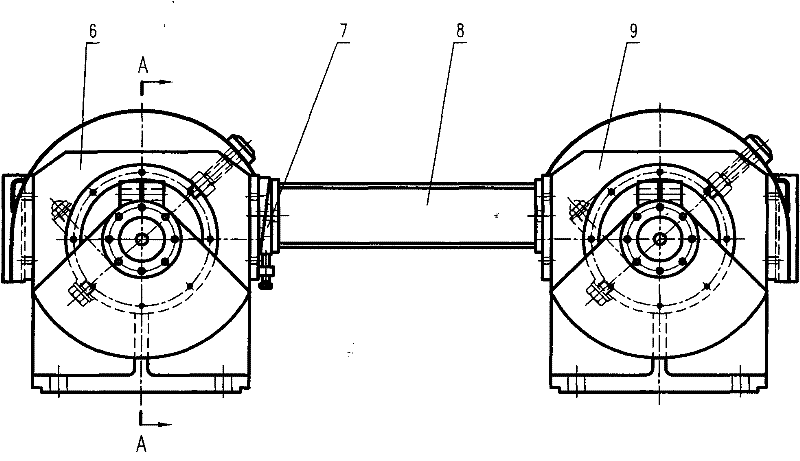

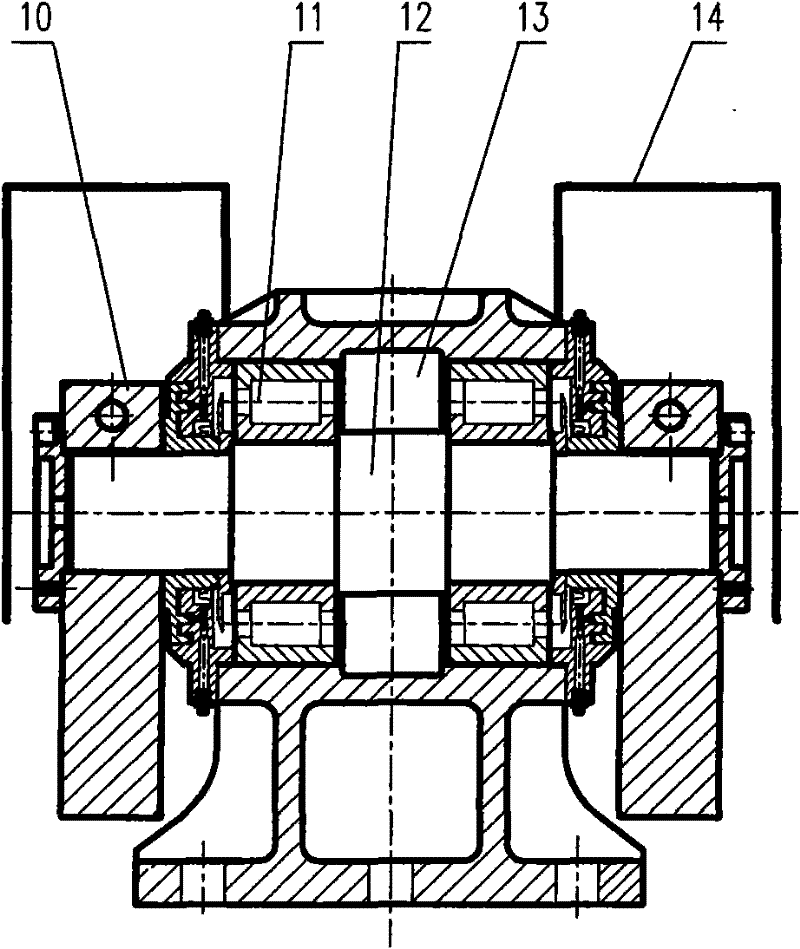

Rectilinear vibrating screen for two groups of split seat-type vibration exciters

The invention relates to a rectilinear vibrating screen for two groups of split seat-type vibration exciters, which belongs to the field of vibrating screening machines. The invention aims to solve the problem of unfavorable stress condition at the screen frame of the rectilinear vibrating screen, and the problem of poor self-synchronizing effect of the two-shaft vibration exciter. The screen frame of the vibrating screen is provided with two vibration exciter mounting beams with a large space, each mounting beam is provided with one group of single-shaft seat-type vibration exciters, the rotation directions of the main shafts of the two single-shaft seat-type vibration exciters are opposite, and the two single-shaft seat-type vibration exciters are respectively connected with motor transmission gears positioned on one or two sides of the screen box; the main shaft of the vibration exciter is installed on the cabinet of vibration exciter through two bearings, and two eccentric blocks are installed on both ends of the main shaft; the two corresponding single-shaft seat-type vibration exciters are assembled together through a bearing beam; and the end of the bearing beam is provided with a wedge-shaped adjusting mechanism capable of fine adjusting the joint gap of the two single-shaft seat-type vibration exciters. In the invention, the vibration exciters can be arranged at a wide space; and the invention has the characteristics of reasonable structure, good synchronizing effect, convenient installation, maintenance and adjustment of the vibration exciters, and the like. The invention is suitable for large rectilinear vibrating screens in various screening operations.

Owner:鞍山鞍重矿山机械有限公司

Multipole ion guide ion trap mass spectrometry with MS/MS.sup.n analysis

InactiveUS8847157B2Rapid mass analysis capabilityTrajectory stabilizationTime-of-flight spectrometersIsotope separationTrappingMass analyzer

A Time-Of-Flight mass analyzer includes a multipole ion guide located in the ion flight path between the ion source and the flight tube of the Time-Of-Flight mass analyzer. The multipole ion guide can be positioned in the ion path between the ion source and the ion pulsing region of the TOF mass analyzer. The multipole ion guide electronics and the ion guide entrance and exit electrostatic lenses are configured to enable trapping or passing through of ions delivered from an atmospheric pressure ion source. The multipole ion guide can be used for ion transmission, trapping and fragmentation, and can reside in one vacuum pumping stage or can extend continuously into more than one vacuum pumping stage.

Owner:PERKINELMER HEALTH SCIENCES INC

Multipole ion guide ion trap mass spectrometry with ms/msn analysis

InactiveUS20110303840A1Rapid mass analysis capabilityTrajectory stabilizationStability-of-path spectrometersTime-of-flight spectrometersIon trap mass spectrometryMass analyzer

A method includes directing ions from an atmospheric pressure ion source to a first ion guide; directing ions in the first ion guide to a second ion guide, the second ion guide being a multipole ion guide extending along an axis; periodically directing ions along the axis; receiving at least some of the ions in a time-of-flight analyzer; accelerating the ions in the time-of-flight mass analyzer orthogonal to the axis; and detecting the accelerated ions.

Owner:PERKINELMER HEALTH SCIENCES INC

Multipole ion guide ion trap mass spectrometry with MS/MSn analysis

InactiveUS8610056B2Rapid mass analysis capabilityTrajectory stabilizationIsotope separationSpectrometer combinationsIon trap mass spectrometryMass analyzer

An apparatus includes an atmospheric pressure ion source; a first vacuum stage and a second vacuum stage separated from the first vacuum stage by a vacuum partition; a first ion guide positioned within a first vacuum stage and arranged to receive ions from the atmospheric pressure ion source; a second ion guide positioned within a second vacuum stage downstream of the first vacuum stage from the atmospheric pressure ion source, the second ion guide being a multipole ion guide arranged to receive ions from the first ion guide; and a time-of-flight mass analyzer that includes an orthogonal pulsing region arranged to receive ions from the second ion guide.

Owner:PERKINELMER HEALTH SCIENCES INC

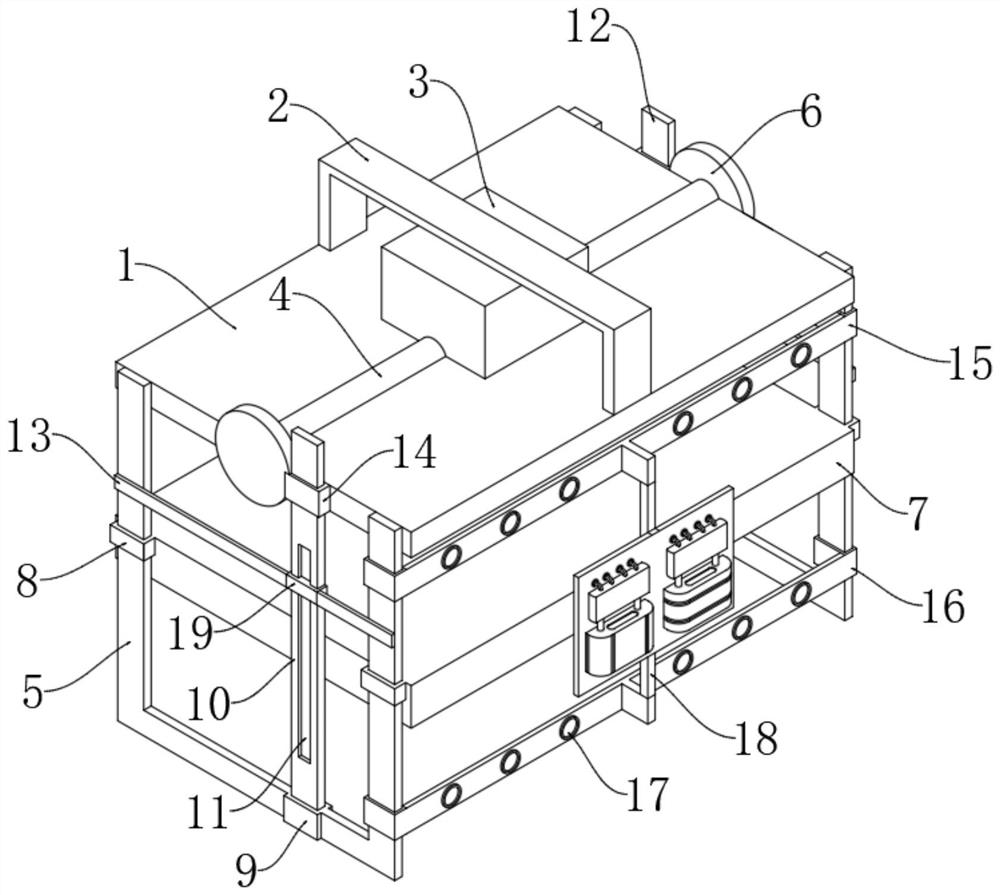

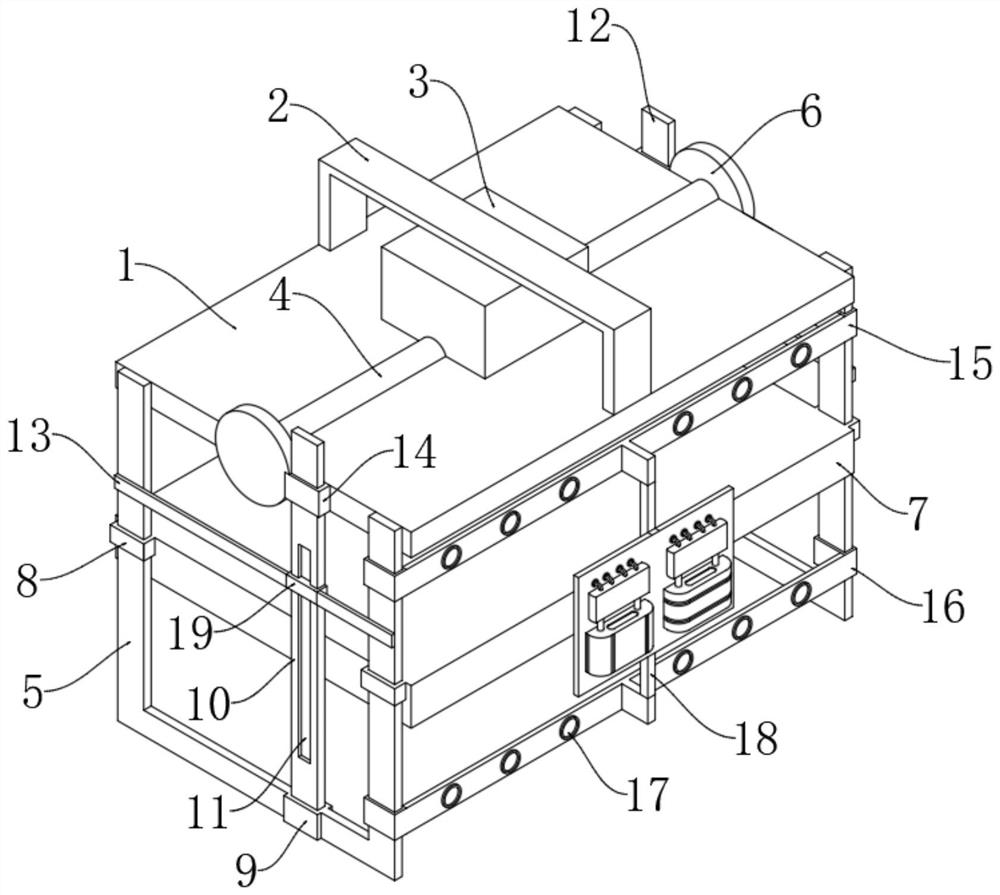

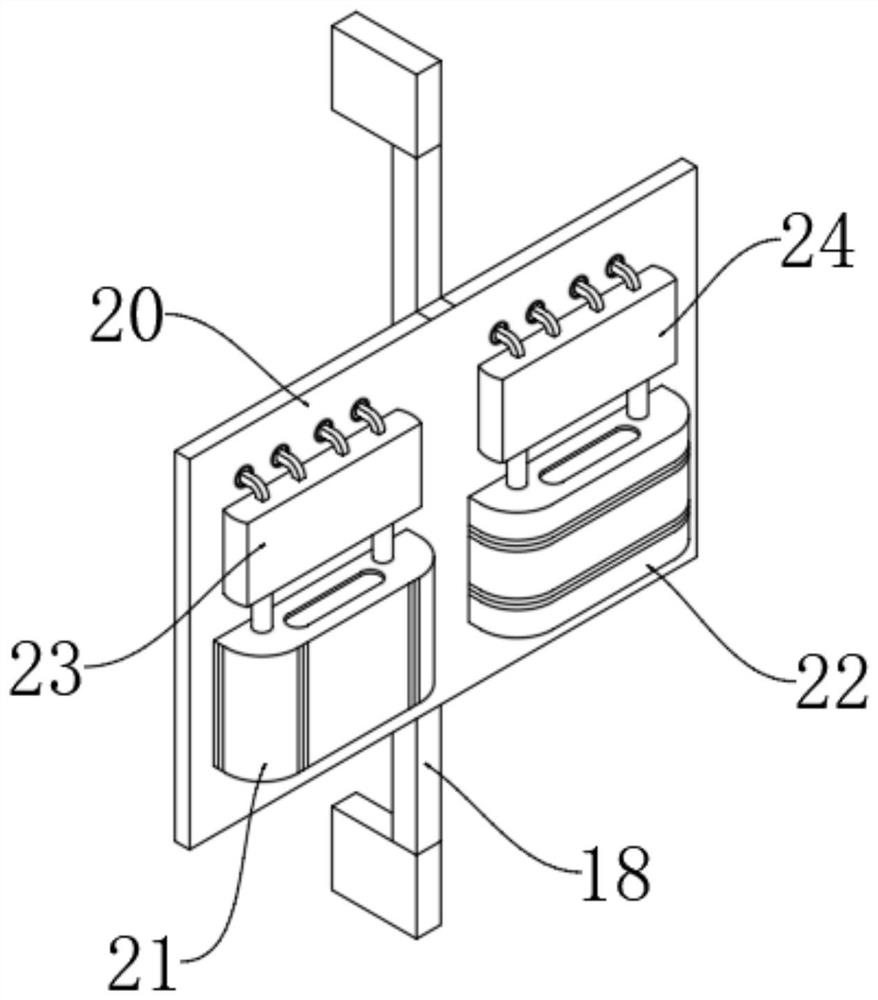

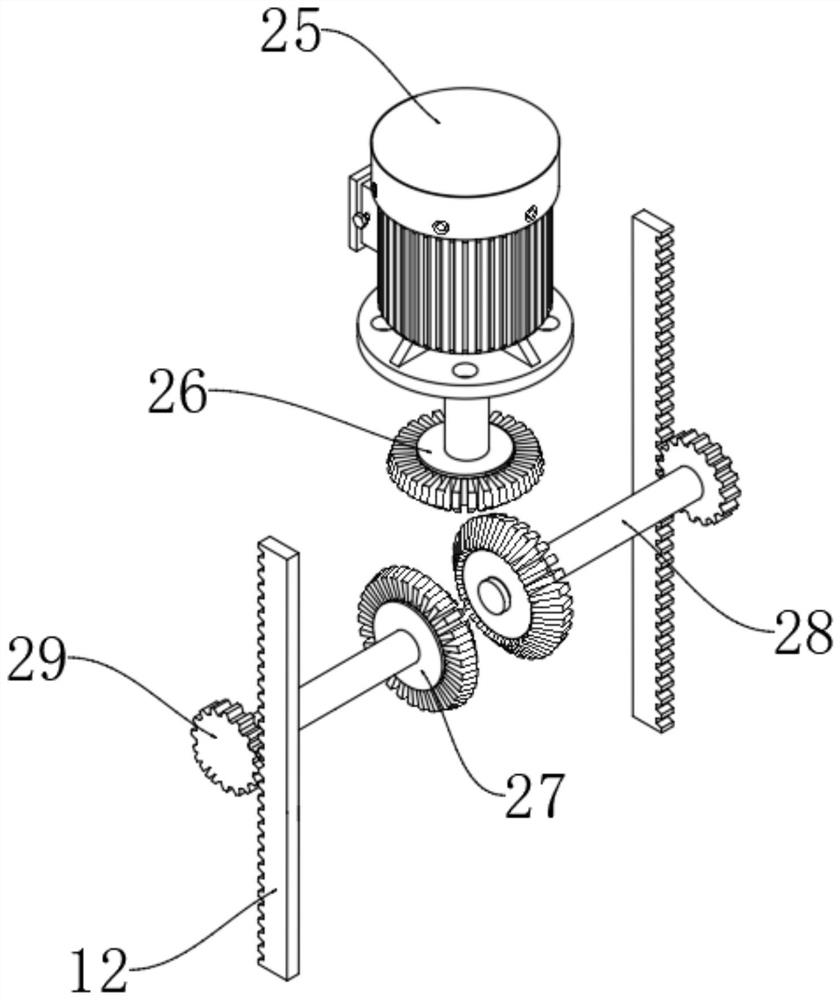

Smashing device for separating bottle cap and bottle body of recycled mineral water bottle

InactiveCN111660461ATorque stabilizationTrajectory stabilizationPlastic recyclingMechanical material recoveryMineralogyEngineering

The invention discloses a smashing device for separating a bottle cap and a bottle body of a recycled mineral water bottle. The device includes a box body, a chamber body is arranged in the box body,two mounting plates are arranged on the inner wall of the rear side of the chamber body, an inflatable device is arranged on the left sides of the two mounting plates, and a bottle body erecting device is arranged on the right sides of the two mounting plates. A transmission device is arranged on the inner wall of the lower side of the box body, the transmission device is used to drive the movement of the mineral water bottle between stations, a bottle cap fragmentation device is arranged on the front side of the transmission device, the bottle cover fragmentation device can smash the bottle cap, a cap screwing device is arranged above the bottle cover fragmentation device, the cap screwing device is used to screw a mineral water bottle cap, a bottle body fragmentation device is arranged on the right side of the transmission device, and the bottle body fragmentation device is used to smash a bottle body. As a result, the device can achieve the separation and smashing of the bottle capand bottle body of the recycled mineral water bottle.

Owner:绍兴上虞信道环保科技有限公司

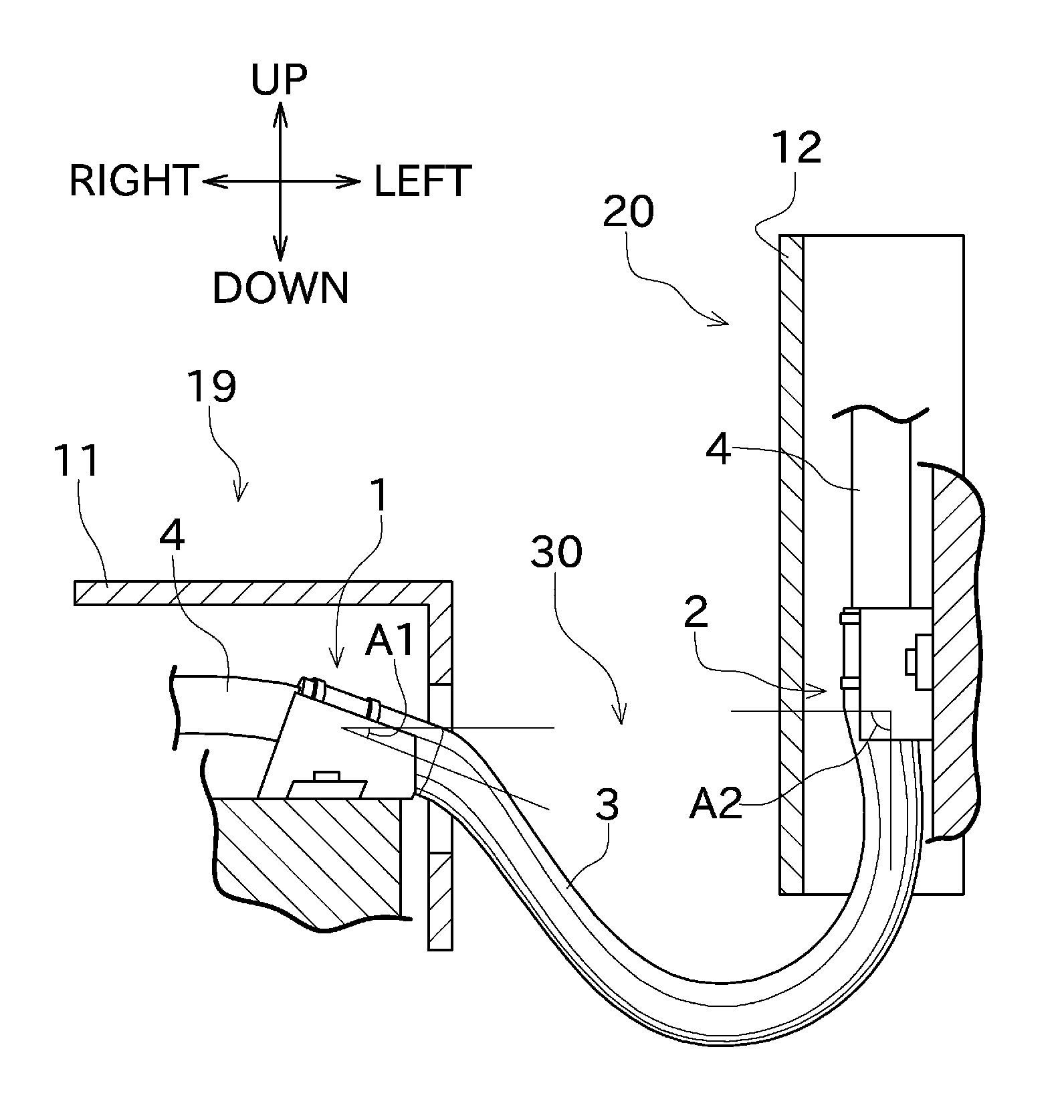

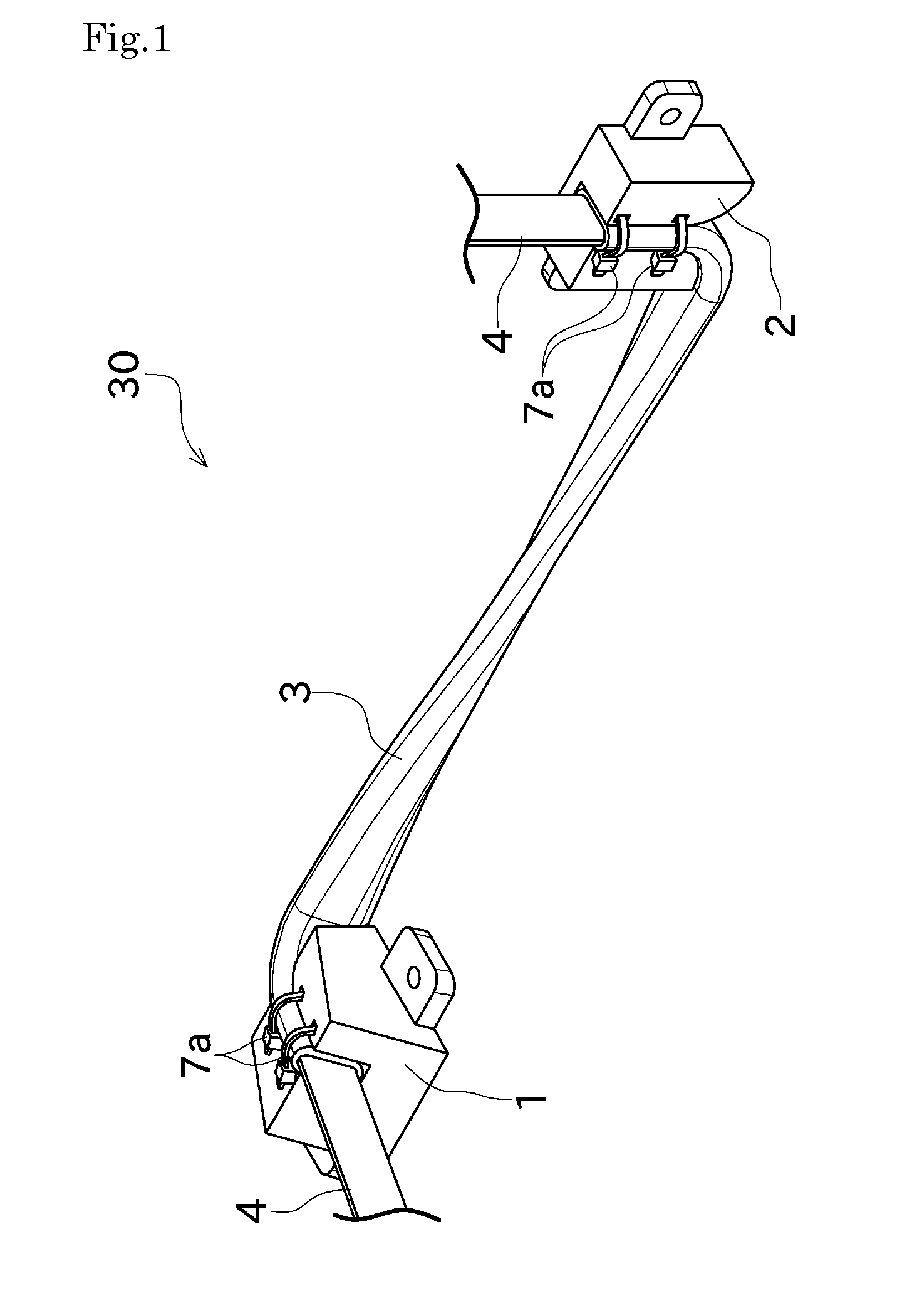

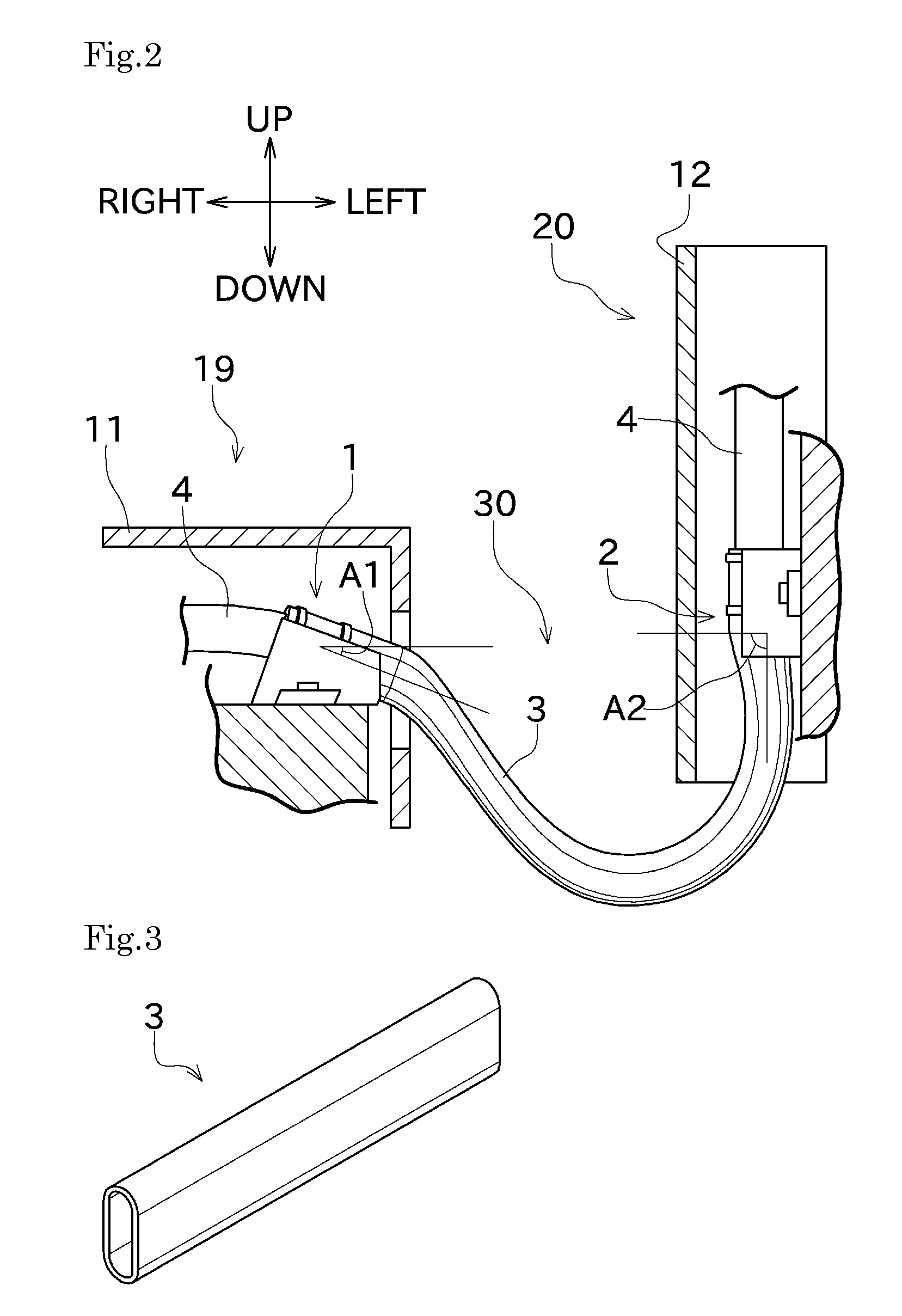

Electric power supply device for sliding door

ActiveUS8816525B2Suppress rapid changesTrajectory stabilizationPipe supportsElectric devicesEngineeringElectric Power Supplies

Owner:FURUKAWA ELECTRIC CO LTD +1

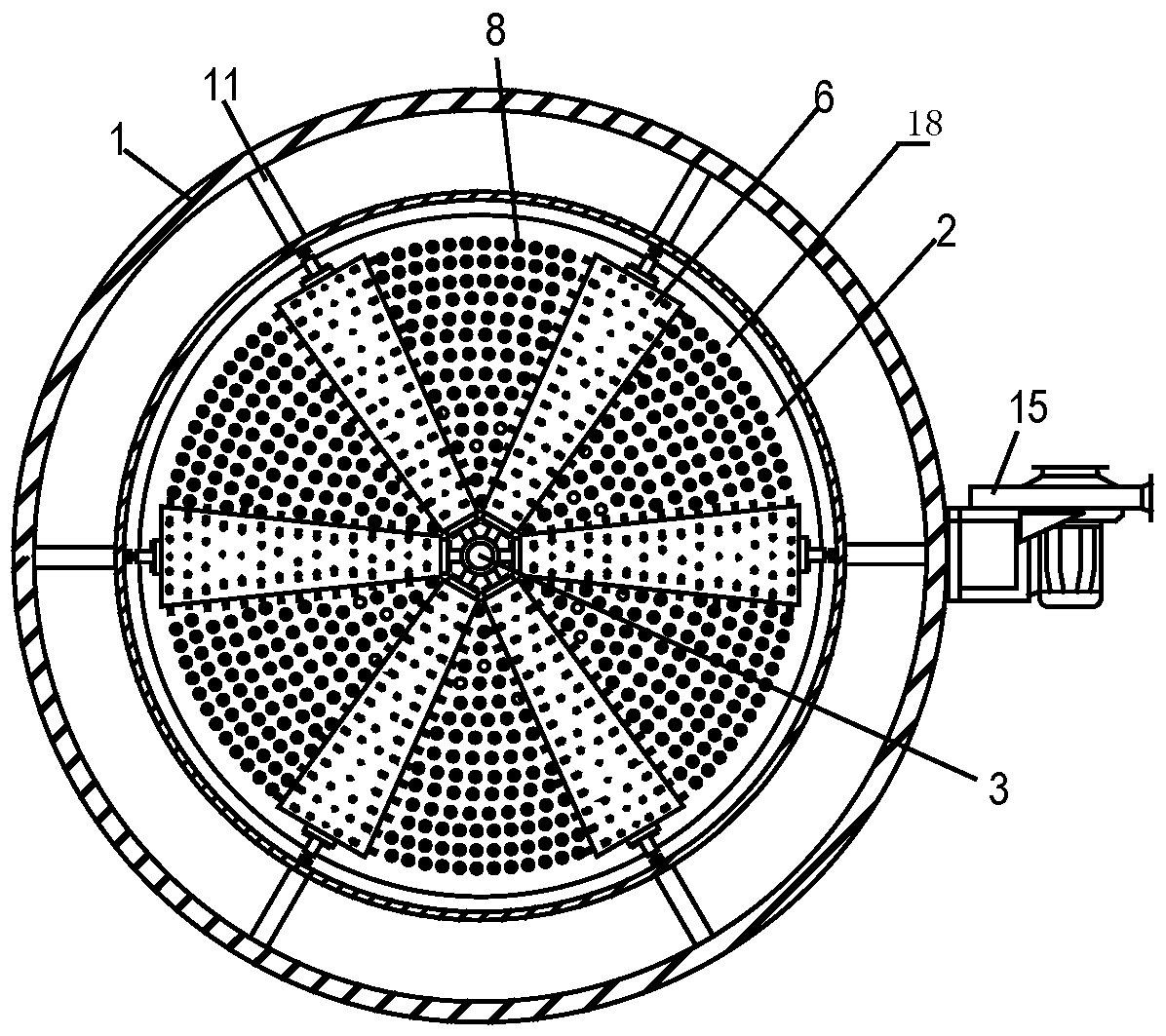

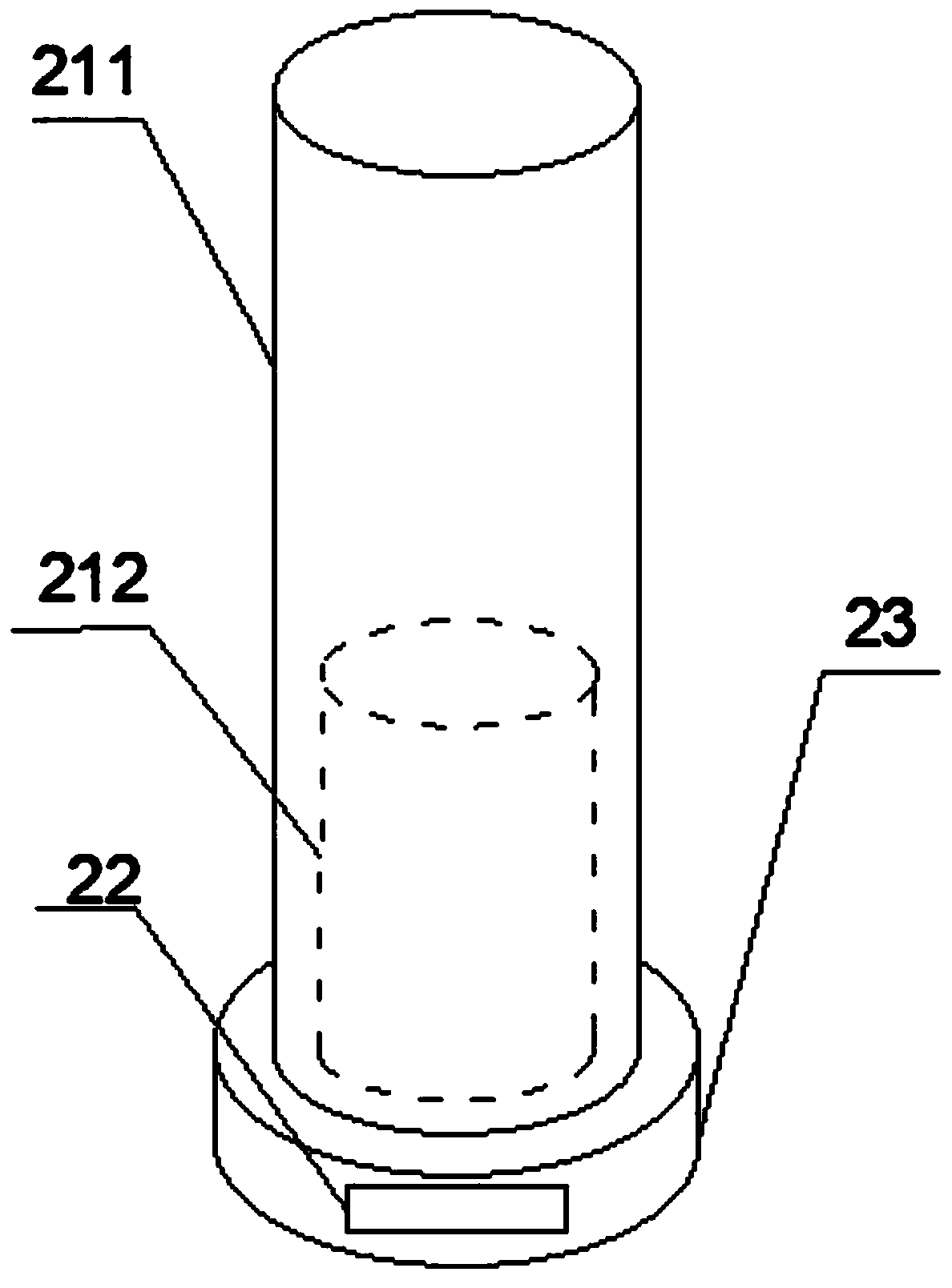

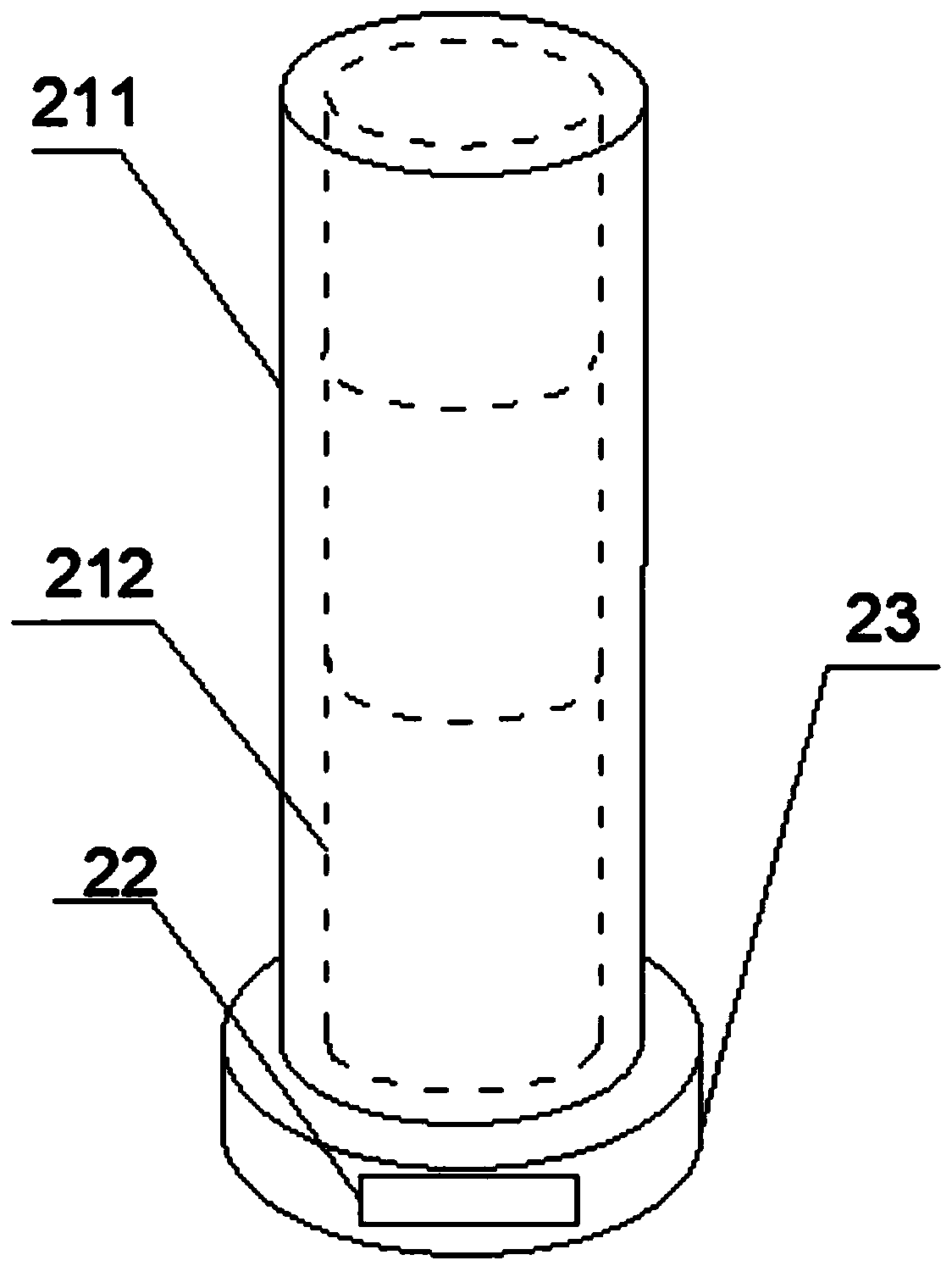

Urea granulating column with high yield

ActiveCN109126633AEasy to recycleIncrease contact areaGranulation by liquid drop formationGranulation by pressingEngineeringDistributor

The invention relates to a urea granulating column with high yield, comprising a column body and a distributor, as well as a squeezing disc that is arranged in the upper portion of the column body; ahollow shaft is arranged in the center of the squeezing disc; a plurality of horizontal center shafts are fixed evenly on the outer periphery of the hollow shaft, each horizontal hollow shaft is hinged to a squeezing roller in penetrating manner, and the bottom edges of each squeezing rollers are attached to the upper surface of the squeezing disc. The granulating blocking problem can be effectively solved by making use of squeezing granulation; each urea granule is squeezed to freely fall in an independent cooling tube; the urea granules are full and solid and have a stable falling trajectory; the urea granules never collide with and stick to other granules; column sticking to the granules is never caused, a water film on a film mesh spreads water so that contact area of the water with urea powder is enlarged, and dust collection effect is significant; the dissolved urea is easy to recycle; humidity in the column herein is unaffected and dust emission is reduced.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

Multipole ion guide ion trap mass spectrometry with ms/msn analysis

InactiveUS20140124661A1Rapid mass analysis capabilityTrajectory stabilizationTime-of-flight spectrometersIsotope separationTrappingMass analyzer

A Time-Of-Flight mass analyzer includes a multipole ion guide located in the ion flight path between the ion source and the flight tube of the Time-Of-Flight mass analyzer. The multipole ion guide can be positioned in the ion path between the ion source and the ion pulsing region of the TOF mass analyzer. The multipole ion guide electronics and the ion guide entrance and exit electrostatic lenses are configured to enable trapping or passing through of ions delivered from an atmospheric pressure ion source. The multipole ion guide can be used for ion transmission, trapping and fragmentation, and can reside in one vacuum pumping stage or can extend continuously into more than one vacuum pumping stage.

Owner:PERKINELMER HEALTH SCIENCES INC

Portable high precision polishing equipment for civil engineering

ActiveCN111730463AEasy to moveEasy to transportGrinding drivesPortable grinding machinesSanderGear wheel

The invention discloses portable high precision polishing equipment for civil engineering, and belongs to the technical field of civil engineering construction. The portable high precision polishing equipment for the civil engineering includes a mounting top plate, a transmission tank is fixed connected with a center of the mounting top plate, a hand rod is arranged on the outside of the transmission tank, two ends of the hand rod are fixedly connected with the upper wall face of the mounting top plate, support frames are fixedly connected with two sides of the mounting top plates, clamping tanks are arranged between the support frames, sleeve blocks A are fixedly connected with two sides of the clamping tanks respectively, and the sleeve blocks A are connected with the support frames in asliding mode. sleeve pipes are fixedly connected with a center of the upper surface of the mounting top plate, the sleeve pipes are arranged on two sides of the transmission tanks respectively, geardisks are fixedly connected with terminal ends of the sleeve pipes, and the gear disks are fixedly connected with the edge of the mounting top plate. The equipment solves the problem that a portable sander lacks a clamping adjustment function and cooling dust removal function in the prior art.

Owner:XIANYANG NORMAL UNIV

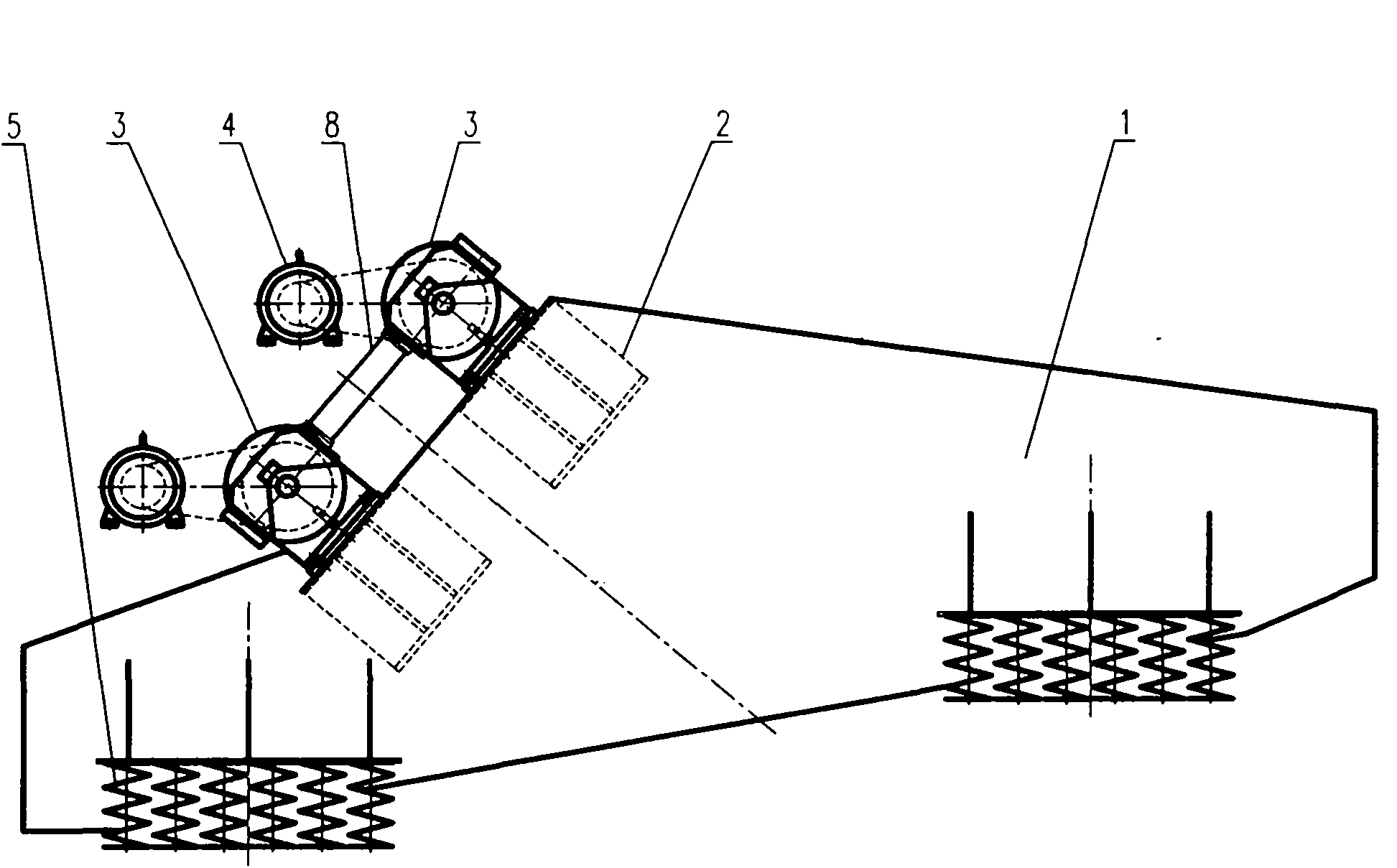

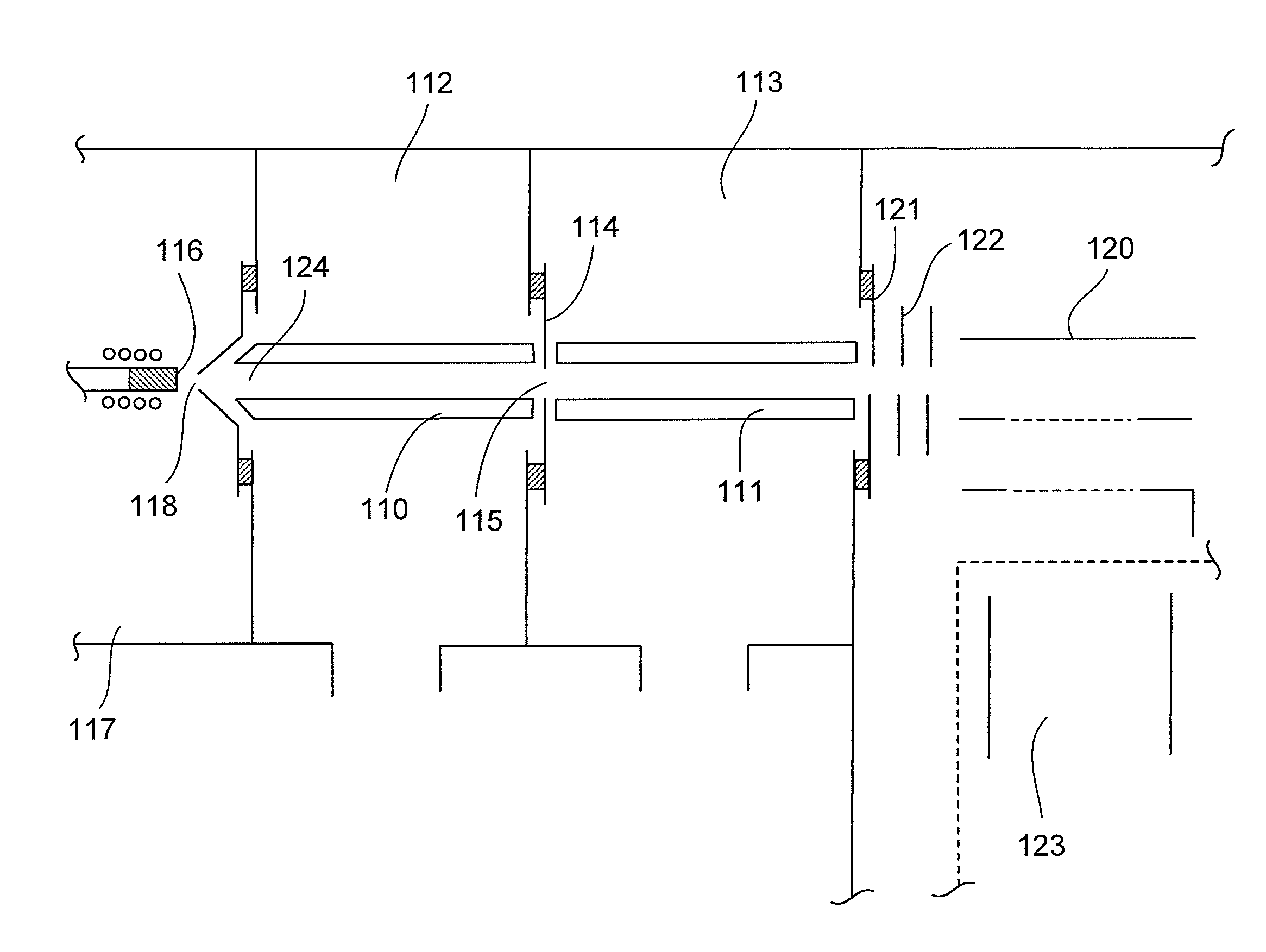

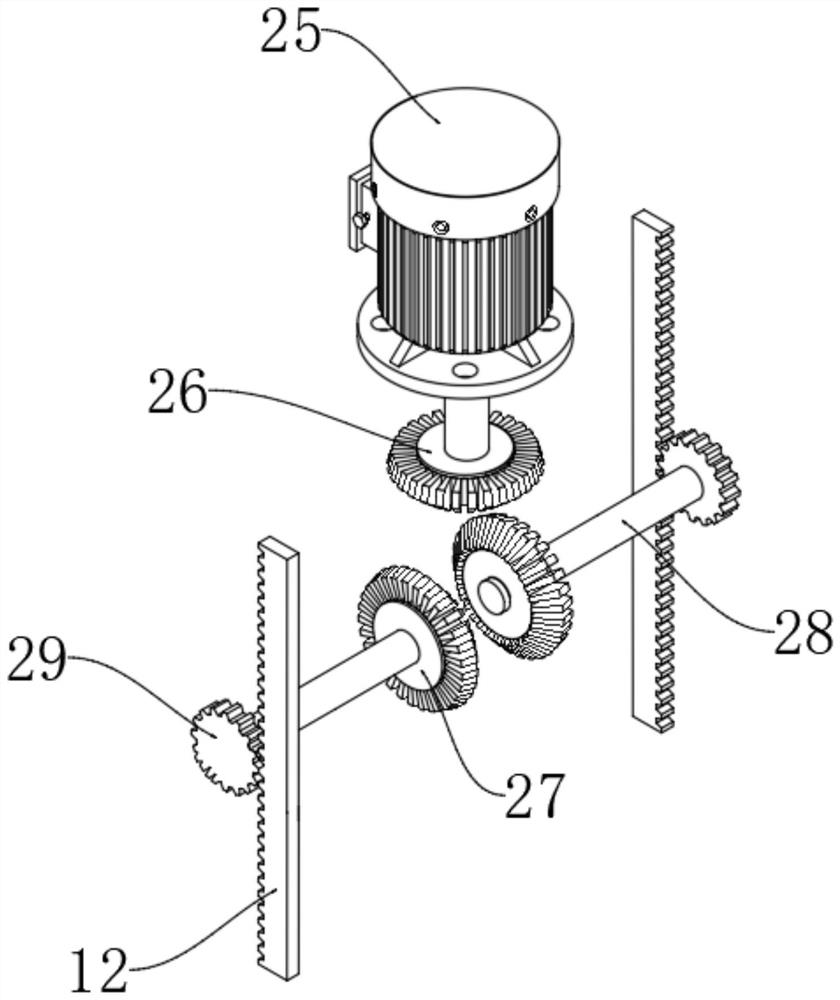

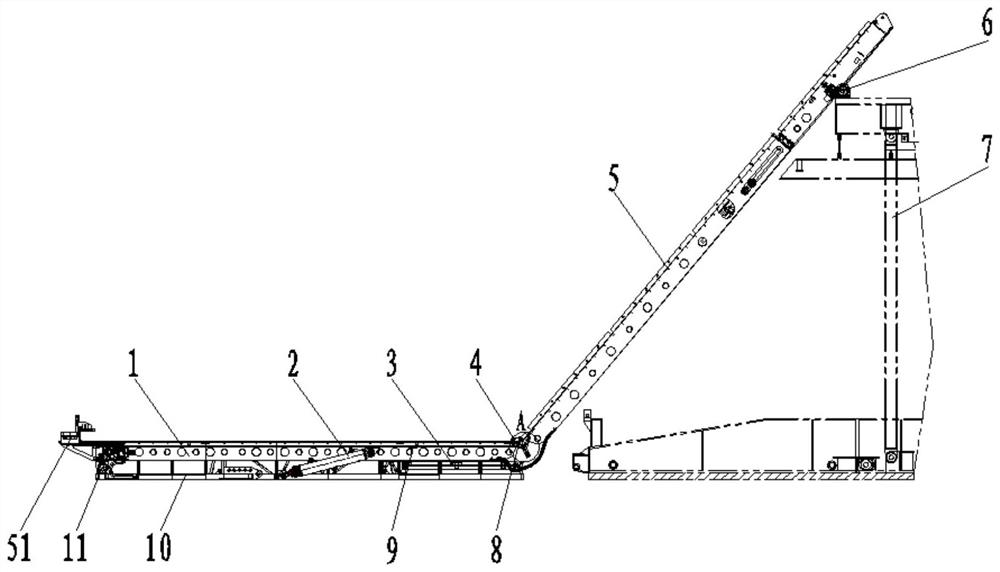

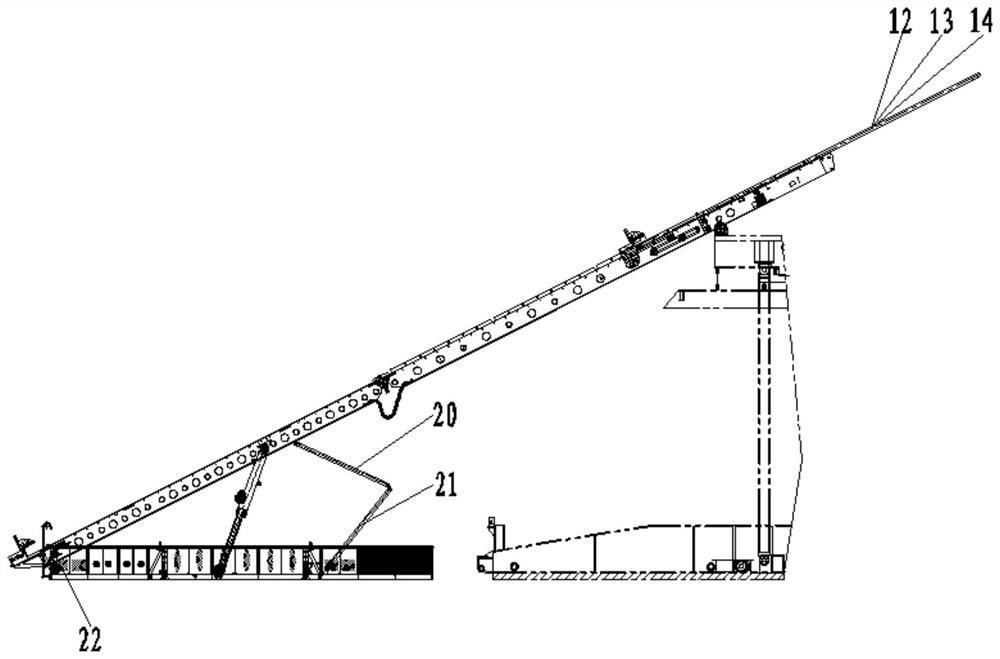

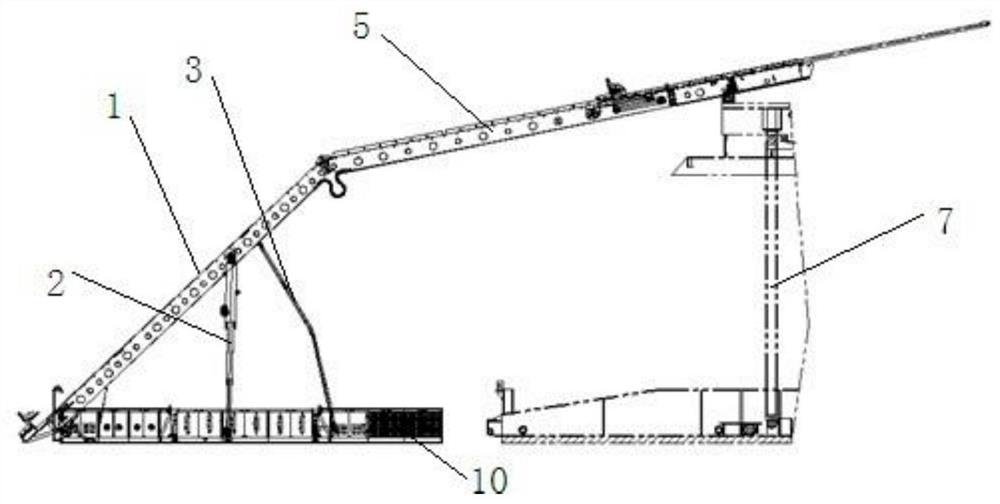

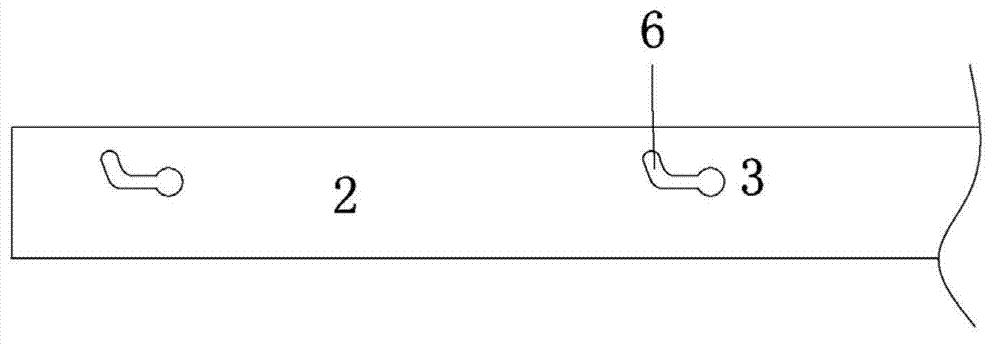

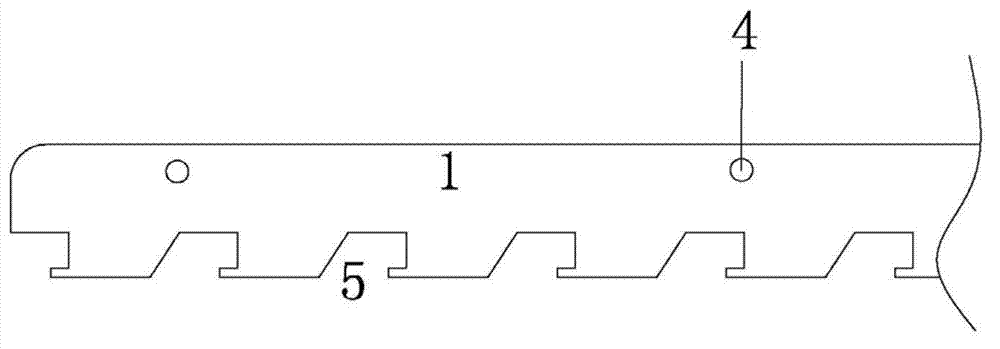

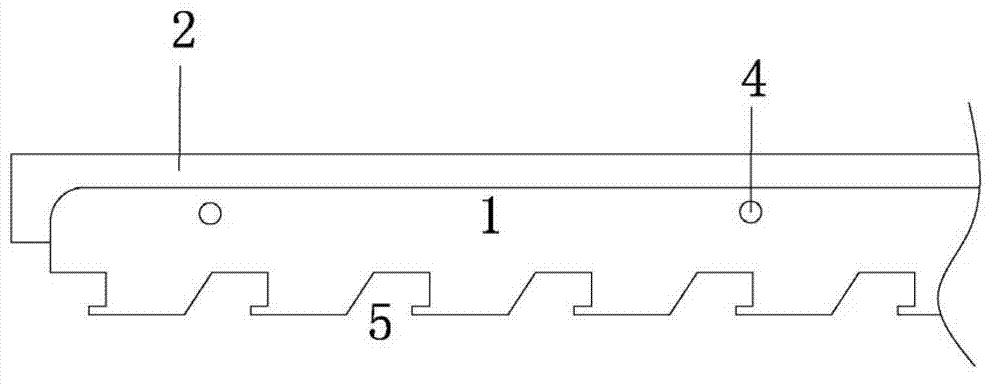

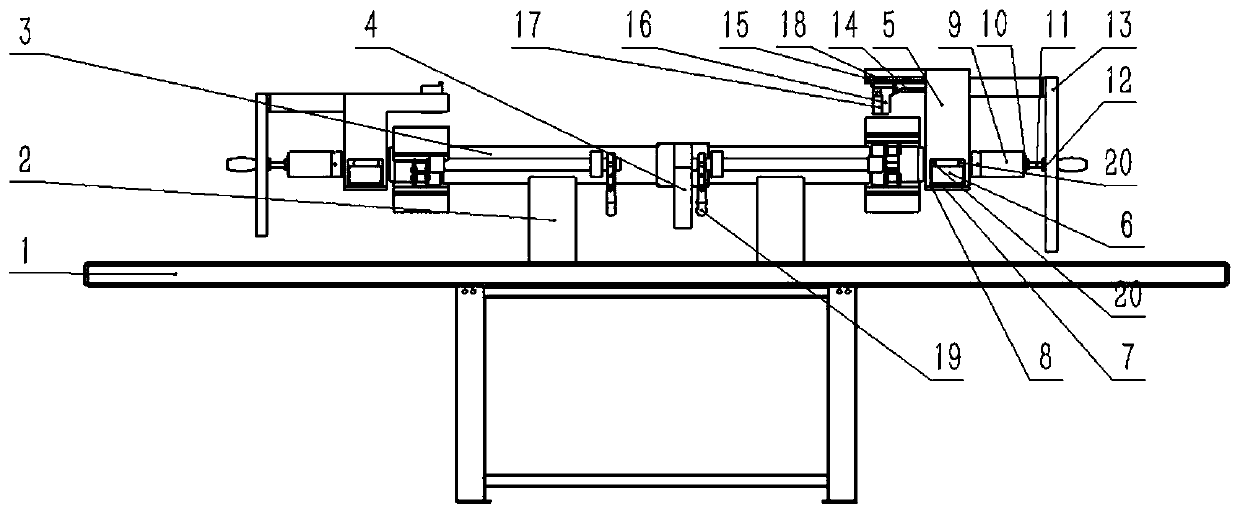

Batch pipe column conveying device and pipe column processing method

ActiveCN112761552ASmooth connectionImprove stressDrilling rodsDrilling casingsHydraulic cylinderLap joint

The invention discloses a batch pipe column conveying device and a pipe column processing method. The batch pipe column conveying device comprises a lower section drill column conveying device and an upper section drill column conveying device which are connected through a chain guide device, wherein a transmission round-link chain is further arranged between the lower section drill column conveying device and the upper section drill column conveying device, and a catwalk base is arranged at the bottom of the lower section drill column conveying device; a drill floor is arranged on one side of the catwalk base, a drill floor idle wheel assembly is welded on the drill floor, the lower portion of the upper section drill column conveying device can be in lap joint with a rolling shaft of the drill floor idle wheel assembly, a support assembly and a lifting hydraulic cylinder are arranged between the lower section drill column conveying device and the catwalk base, and a pipe arranging frame is arranged on the catwalk base. The upper section drill column conveying device and the lower section drill column conveying device can carry a plurality of pipe columns to be rapidly unfolded during lifting, after the pipe columns are unfolded to a proper angle, a small tackle can push the pipe columns to directly reach a proper position of the drill floor from the lower section of the drill column conveying device, meanwhile, the pipe columns can be separated one by one, and connection of an elevator and a single pipe column is facilitated.

Owner:中油国家油气钻井装备工程技术研究中心有限公司 +2

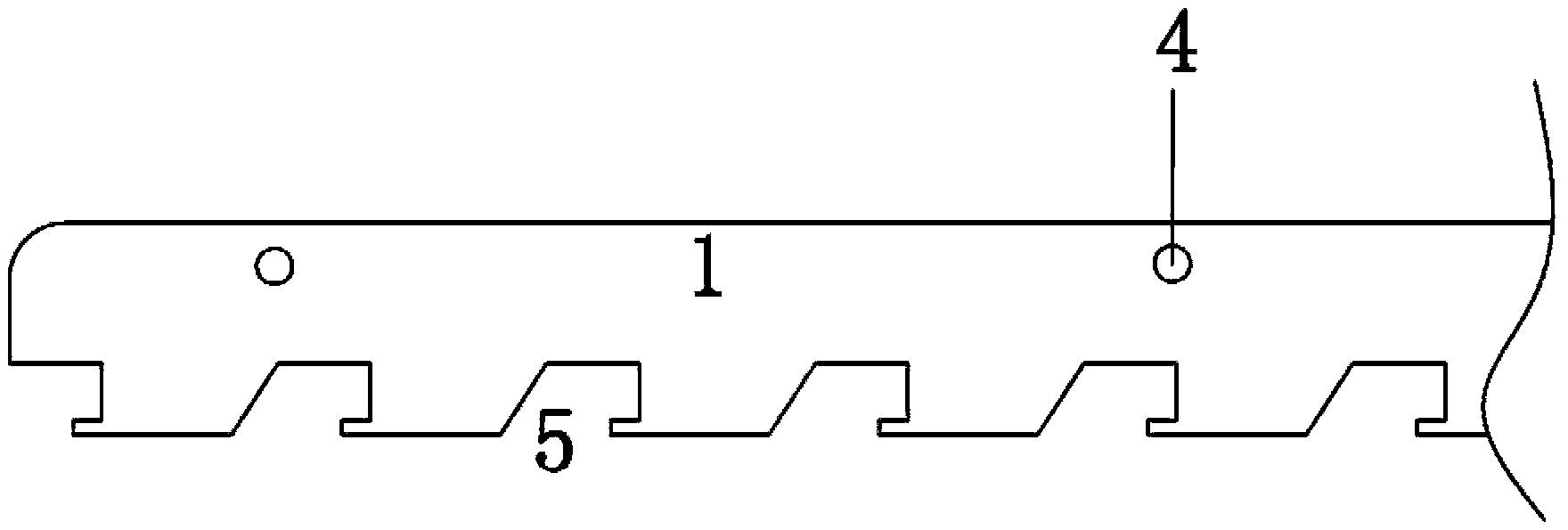

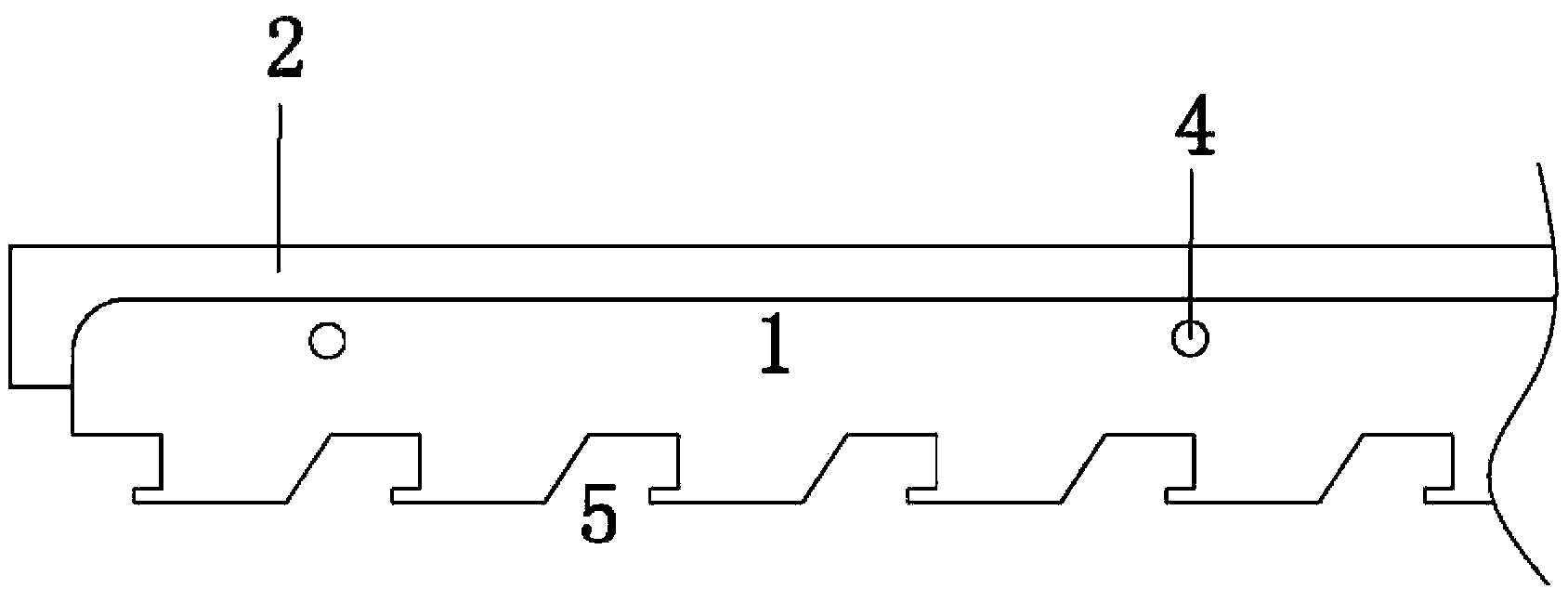

String-up switching mechanism of winding machine

The invention provides a string-up switching mechanism of a winding machine, and relates to the field of textile machinery. The string-up switching mechanism comprises a move-down silk plate and a shoveling plate, wherein a slideway is arranged on the shoveling plate, and a sliding head matched with the slideway is arranged on the move-down silk plate; a groove for hooking and pulling a silk beam is formed in one side of the move-down silk plate; and a bending way opposite to the one side of the groove is arranged at the slideway. The string-up switching mechanism of the winding machine has high string-up switching success rate, the waste silk quantity can be greatly reduced, and meanwhile the product quality is increased. As the improvement cost is low, the string-up switching mechanism is also suitable for large-range popularization and application.

Owner:JIANGSU CHALLEN FIBER S&T

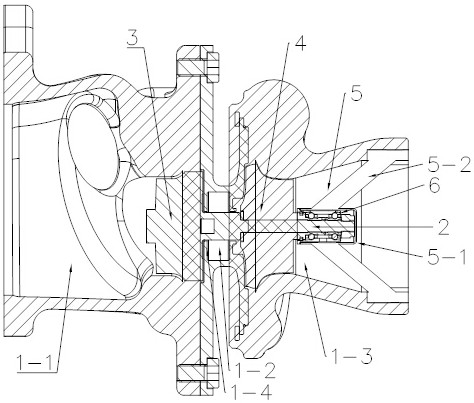

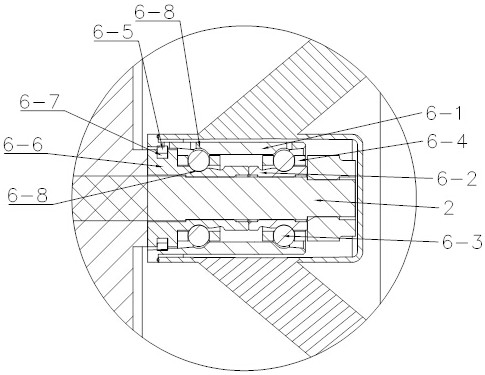

Turbocharger with external ball bearing

ActiveCN111648983AImprove rigidityReduce volumeInternal combustion piston enginesPump componentsRotational axisBall bearing

The invention discloses a turbocharger with an external ball bearing. According to the turbocharger, a ball bearing which supports the rotation of a rotating shaft is moved from an intermediate cavityto a compressed air cavity, and a support frame body fixed in the compressed air cavity and the ball bearing are matched to support the rotating shaft. The wheel distance between a turbine and a compressor in the turbocharger can be reduced, and the rigidity of the rotating shaft can be greatly improved, so that the trajectory of the rotating shaft and an axis is more stable when the rotating shaft rotates at high speed. The structure of the support frame body, the ball bearing and the rotating shaft can withstand a certain axial force and radial force without adding an additional thrust bearing design. The volume of the intermediate cavity can be greatly reduced, and the overall structure is simpler. Meanwhile, the ball bearing is placed outside the compressed air cavity to prevent the ball bearing from transmitting the high temperature in a turbine cavity, avoid the aging of the oil in the ball bearing, and prolong the service life.

Owner:宁波丰沃增压科技股份有限公司

An autonomous tracking device and control method for a moving target of a rotary-wing unmanned aerial vehicle

ActiveCN105652891BImprove real-time performanceImprove smoothnessTarget-seeking controlFlight vehicleWireless image transmission

The invention relates to the technical field of unmanned gyroplane autonomous tracking, in particular to an unmanned gyroplane moving target autonomous tracking device based on a pan-tilt camera and an airborne sensor. The unmanned gyroplane moving target autonomous tracking device comprises an aircraft and a ground station. The aircraft comprises an aircraft controller, an aircraft propeller motor connected with the aircraft controller, and a pan-tilt motor. The pan-tilt motor is connected with the pan-tilt camera. A wireless image transmission module and a wireless data transmission module are arranged between the aircraft and the ground station. The aircraft and the ground station are connected through the wireless image transmission module and the wireless data transmission module. Images obtained by the airborne pan-tilt camera serve as input of a system, coordinates of a target in the images are obtained on the ground station through a Struck algorithm, modeling is conducted on the coordinates of the target through a uniformly accelerated motion (CA) model, the control quantity of a pan-tilt is designed according to the coordinates, estimated through modeling, of the target, and accordingly tracking instantaneity and smoothness of the pan-tilt camera are guaranteed.

Owner:SUN YAT SEN UNIV

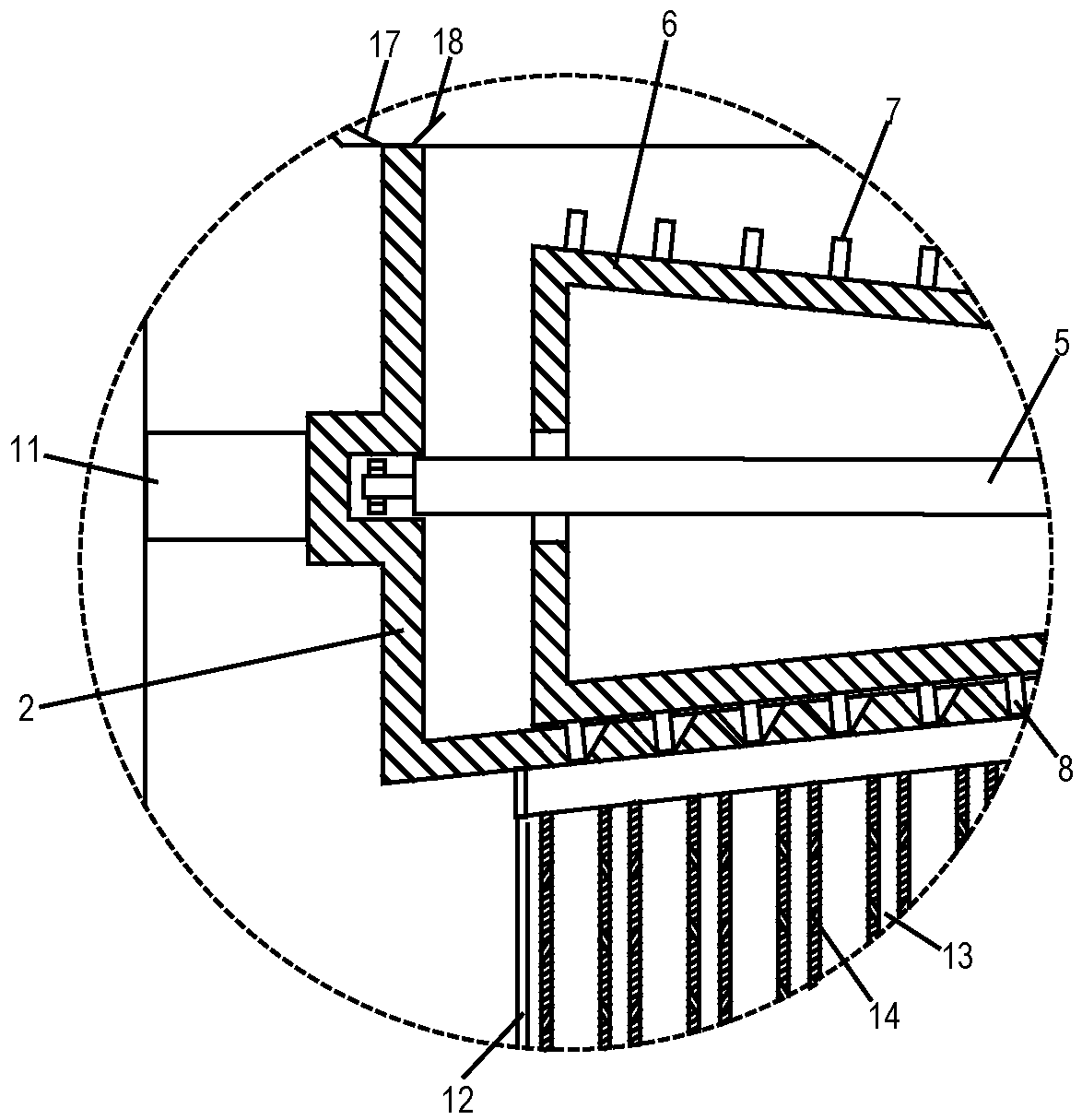

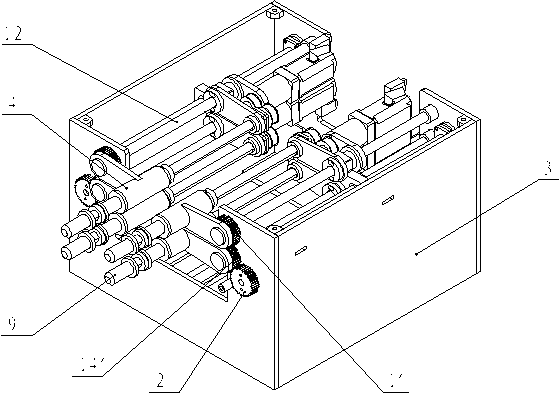

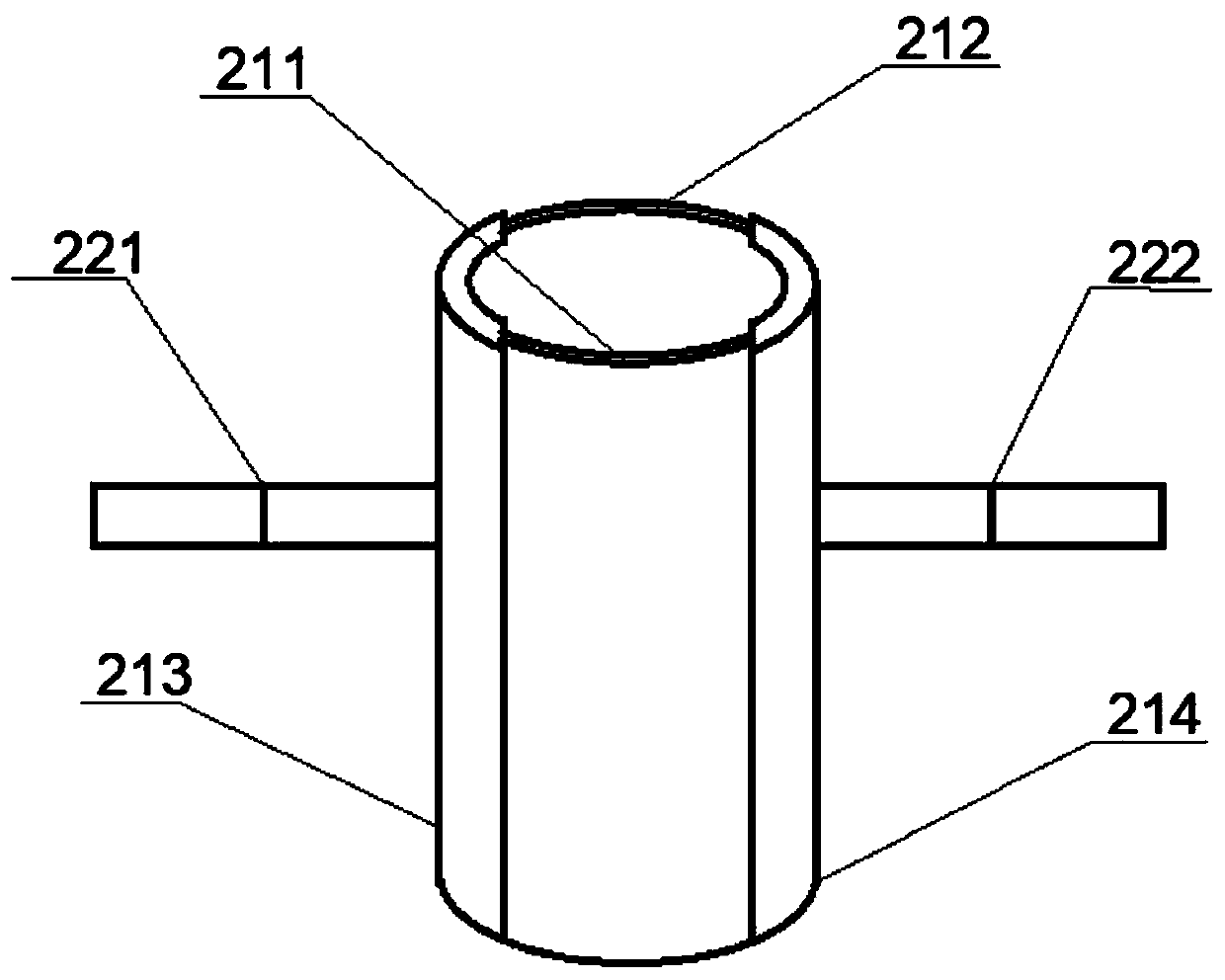

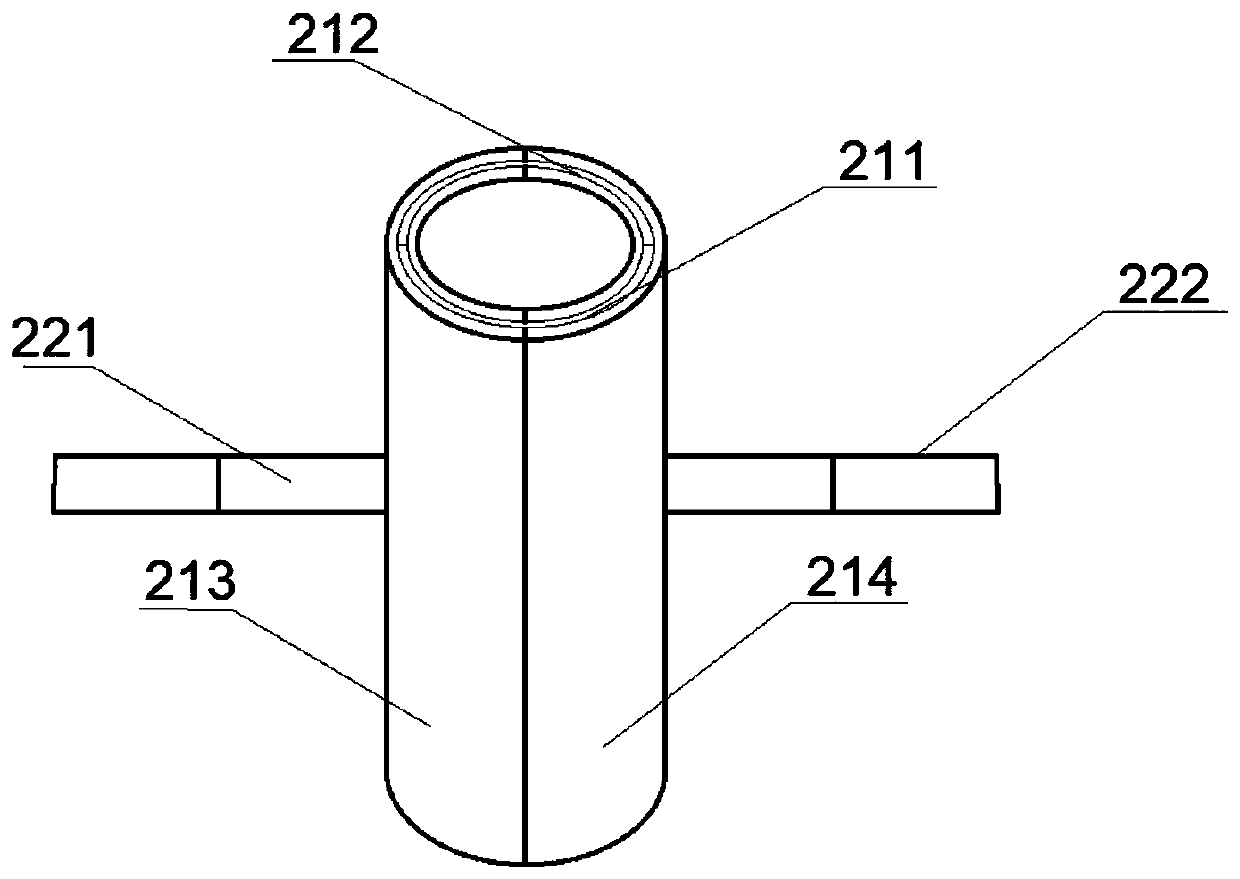

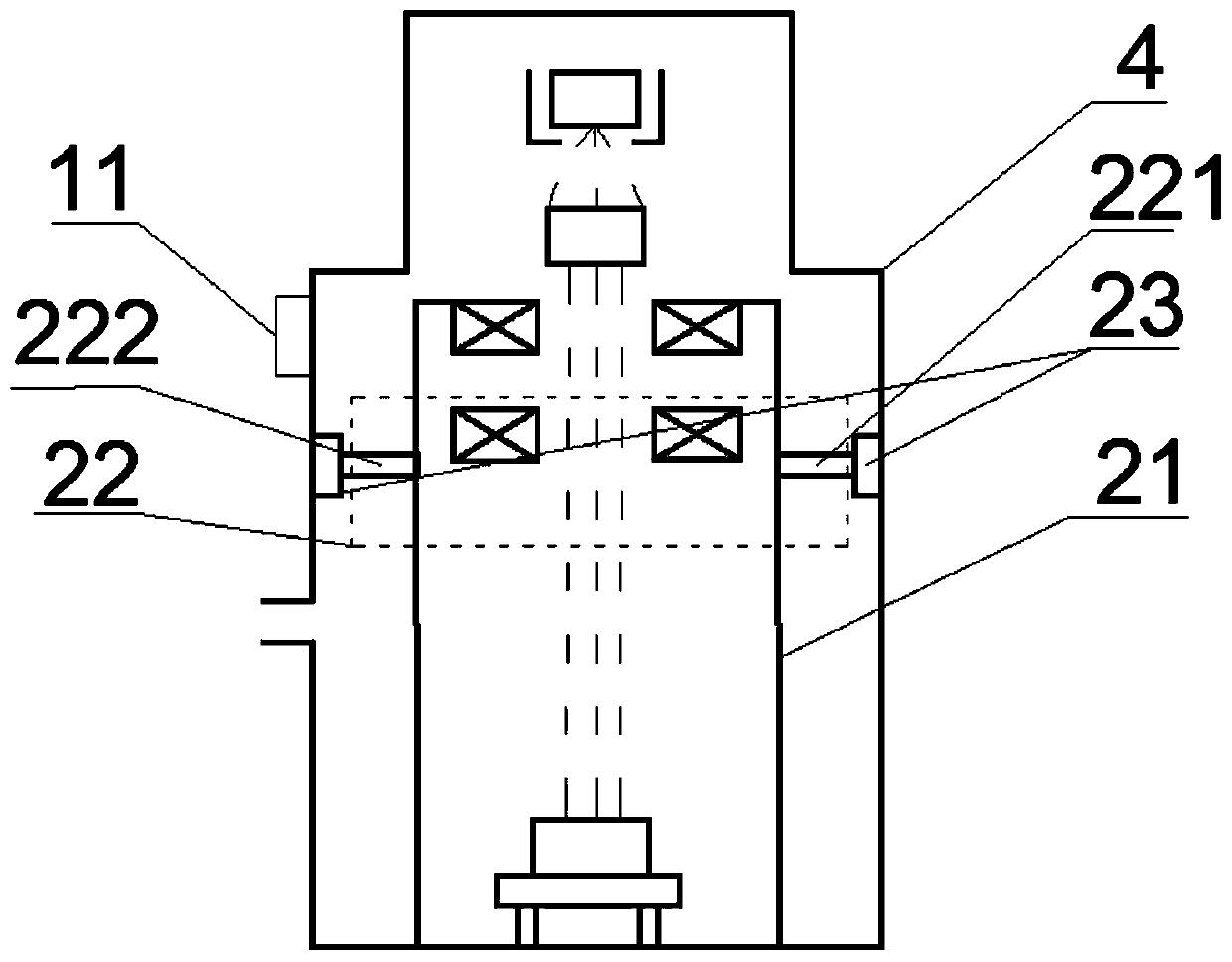

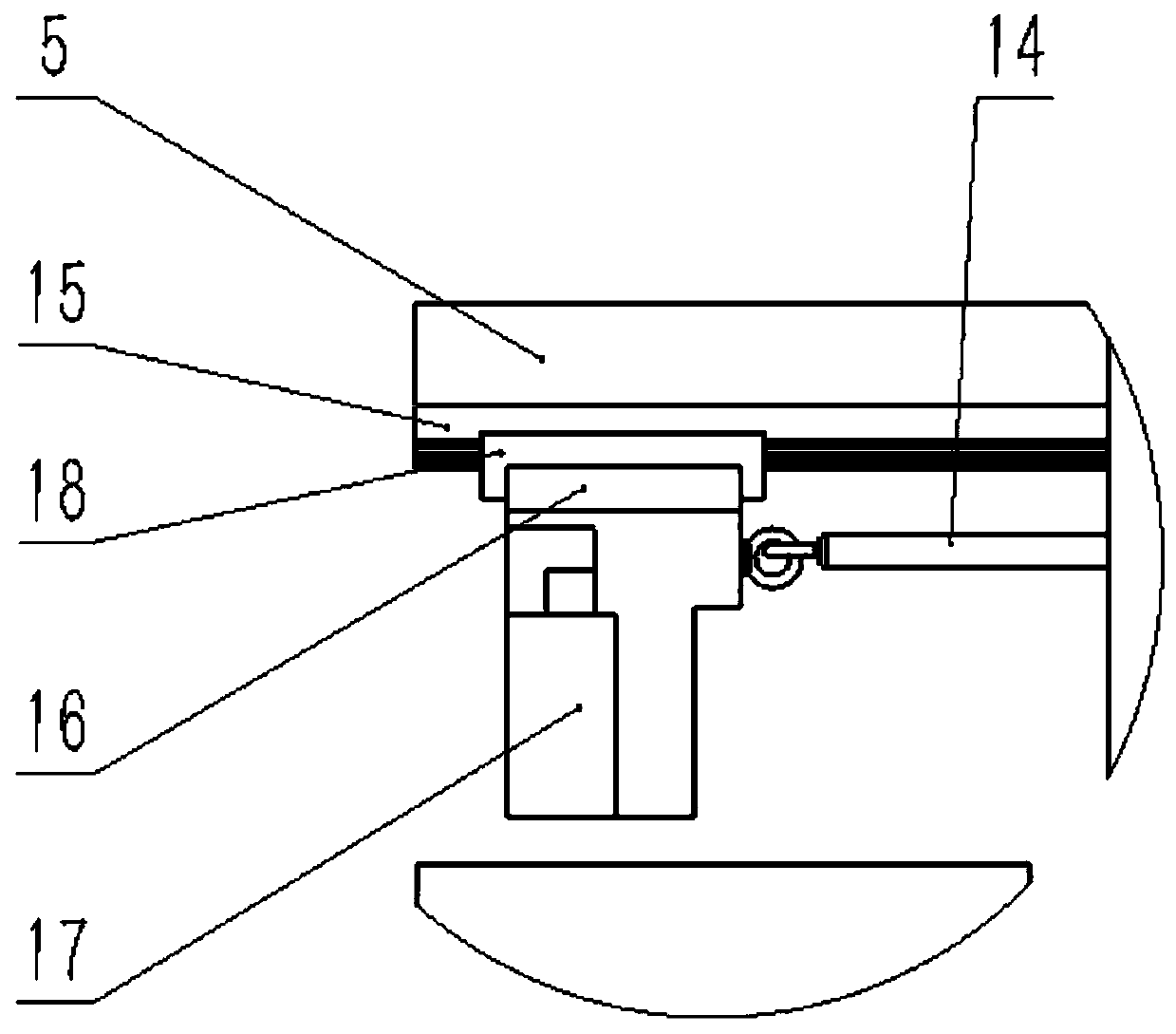

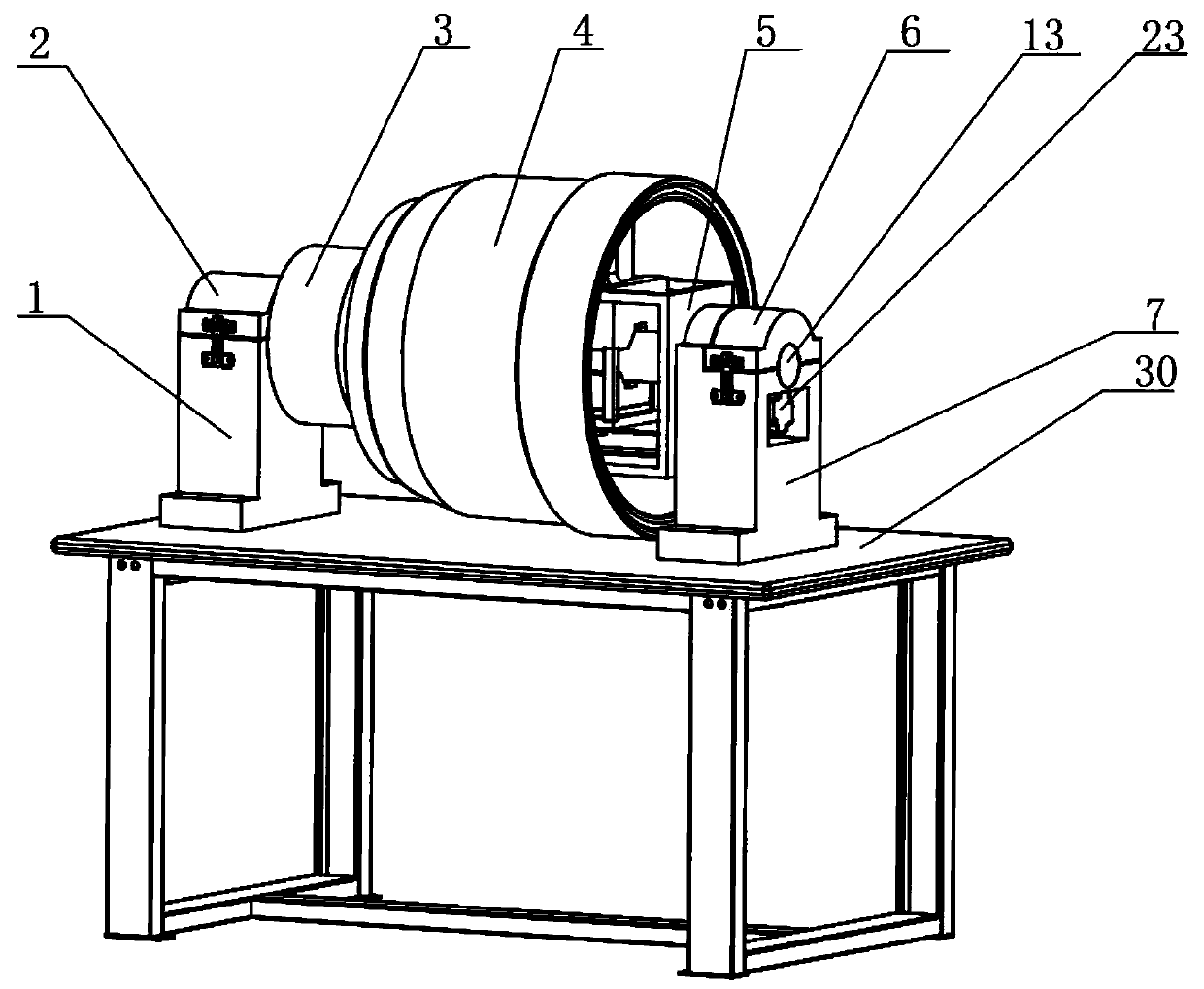

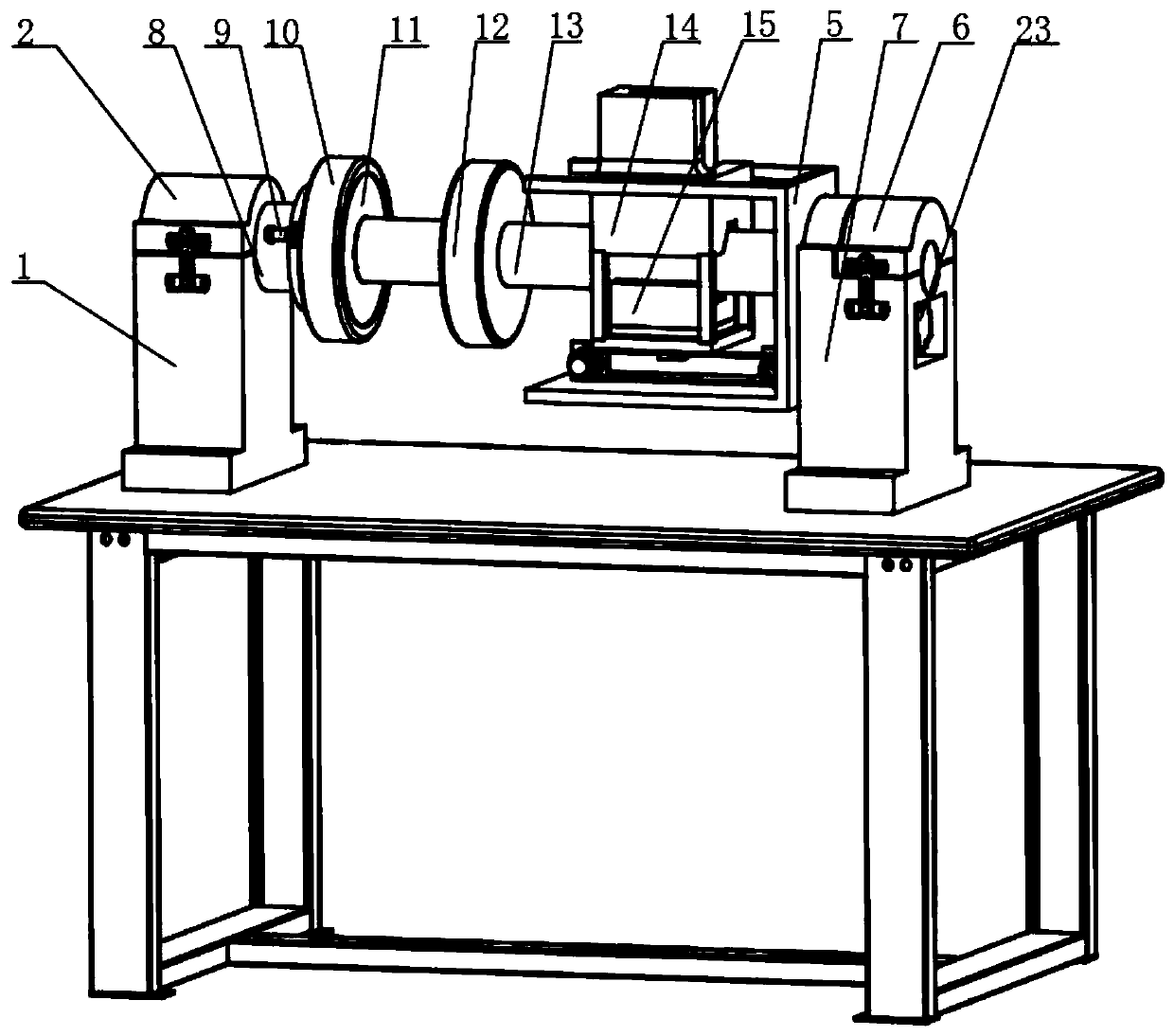

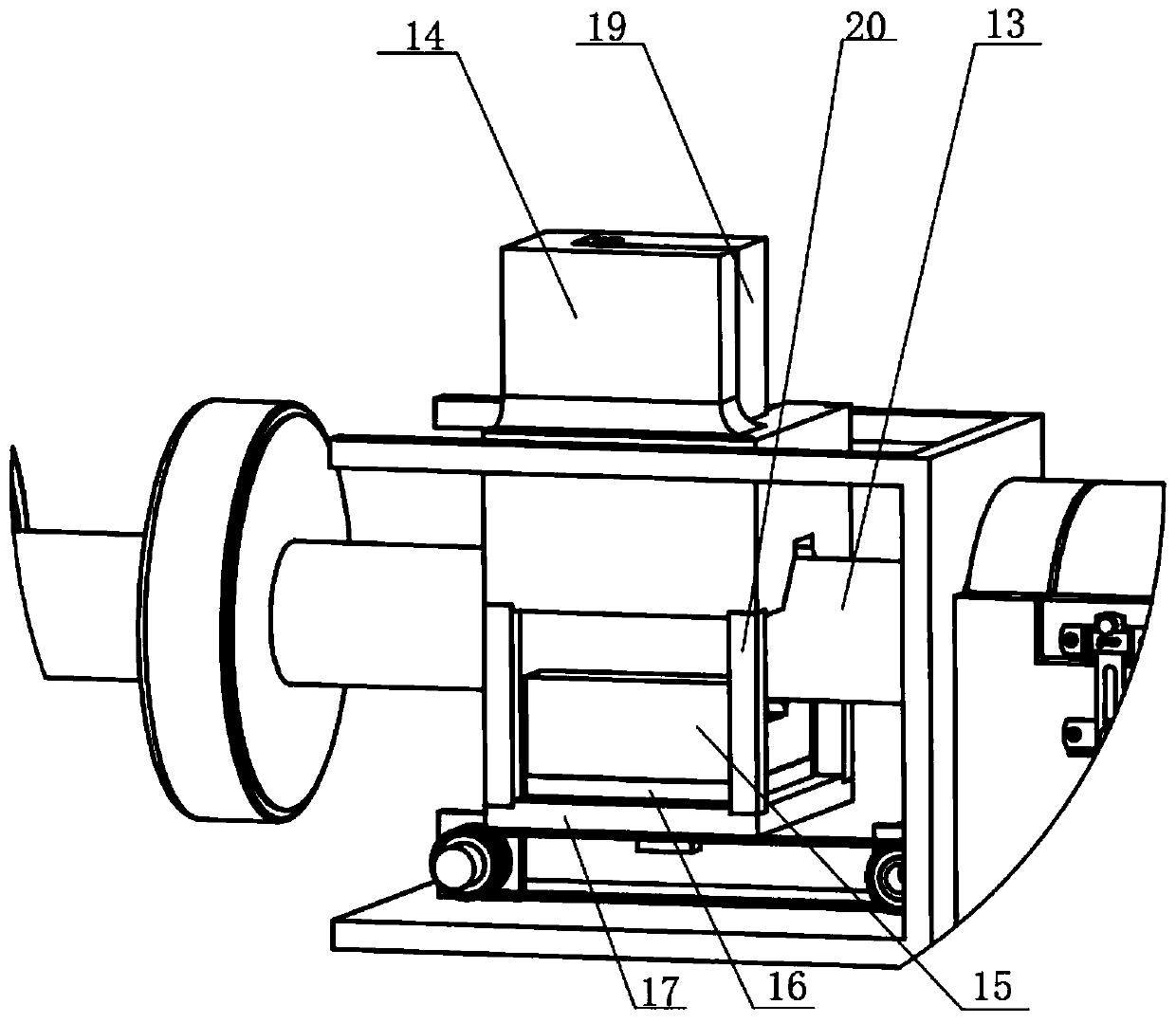

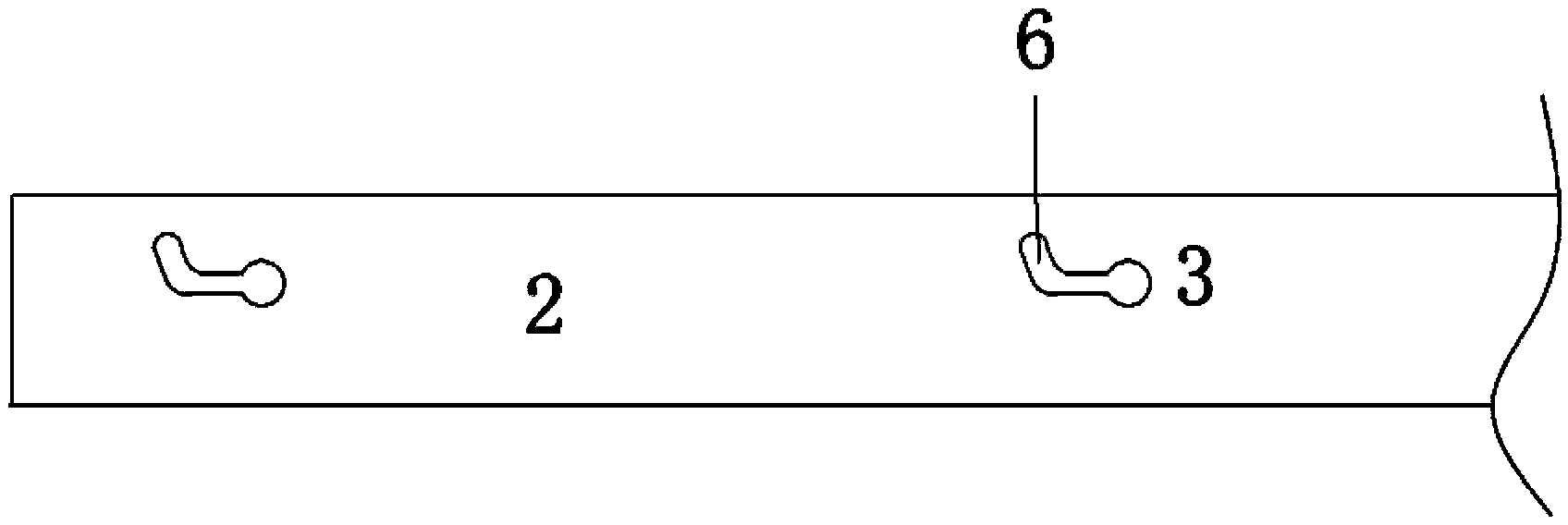

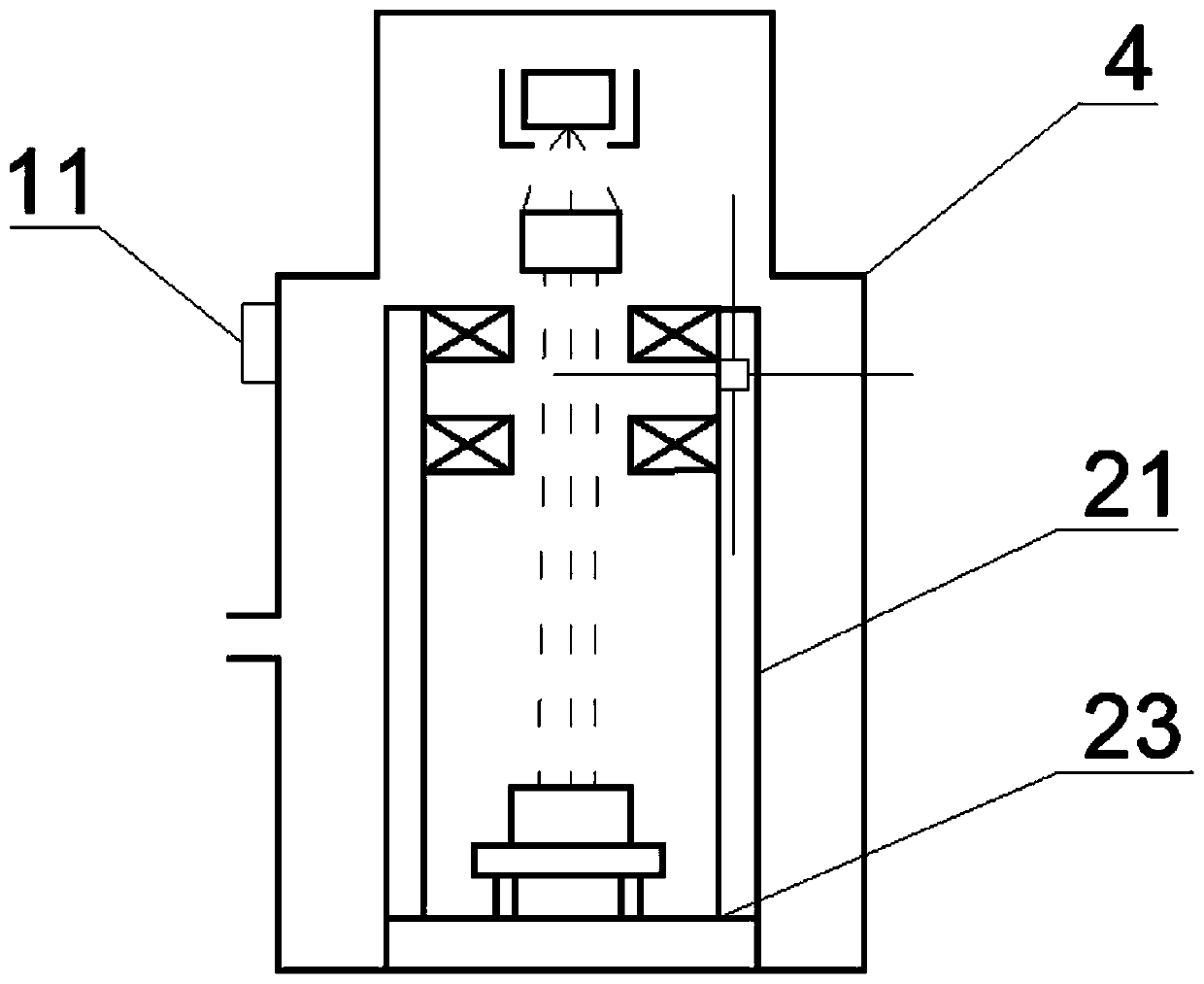

Tyre movement mechanism in X-ray tyre testing equipment

ActiveCN102445459BEasy to processLow costMaterial analysis using wave/particle radiationX-rayTire rotation

The invention relates to a tyre movement mechanism in X-ray tyre testing equipment. The invention belongs to the field of industrial nondestructive testing. The tyre movement mechanism comprises a tyre bracing execution mechanism, a tyre expending mechanism and a tyre rotating mechanism. The main body of the tyre bracing execution mechanism comprises two sets of gears arranged symmetrically, wherein the two sets of gears operate independently relative to each other. Each set of gears comprises a driving gear, a first driven gear, and a second driven gear. The first driven gears and the second driven gears operate under the driving of the driving gears. Tyre bracing tumblers are fixed on the first driven gears and the second driven gears. Cantilever supporting assemblies are arranged on the tyre bracing tumblers. Transmission sleeves are fixed on end faces of rotation sleeves. Tangential circle profile connection transmission is carried out between tyre bracing shafts and the transmission sleeves. With the mechanism provided by the invention, the smooth and stable operation of the tyre bracing tumblers is ensured, the testing precision is high, the processing cost is low, and the installation and adjustment are simple. The mechanism is suitable to be used for testing tyres with different sizes.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

Portable high-precision grinding equipment for civil engineering

ActiveCN111730463BEasy to moveEasy to transportGrinding drivesPortable grinding machinesSanderGear wheel

The invention discloses portable high-precision grinding equipment for civil engineering, which belongs to the technical field of civil engineering construction. A portable high-precision grinding equipment for civil engineering, including an installation top plate, a transmission box is fixedly connected to the center of the installation top plate, and a handle bar is arranged on the outside of the transmission box, and the two ends of the handle bar are fixedly connected to the installation top plate Wall surface; brackets are fixedly connected to both sides of the installation top plate, a clamping box is arranged between the brackets, and sets of blocks A are fixedly connected to both sides of the clamping box, and the sets of blocks A are slidably connected to the brackets; The center of the upper surface of the installation top plate is fixedly connected with a sleeve, the sleeves are respectively arranged on both sides of the transmission box, the end of the sleeve is fixedly connected with a gear plate, and the gear plate is fixedly connected to the edge of the installation top plate; the invention solves the problem of The problem that the portable grinding machine in the prior art lacks the clamping adjustment function and the cooling and dust removal function is solved.

Owner:XIANYANG NORMAL UNIV

Electron beam welding anti-magnetic interference device

ActiveCN108746976BTrajectory stabilizationImprove welding precisionElectron beam welding apparatusMagnetic disturbanceElectron beam machining

Owner:SHENYANG JINCHANG LANYU NEW MATERIAL CO LTD

Vehicle brake pad surface total run-out detection device

ActiveCN111156941ARotate synchronouslySynchronized MobilityMeasurement devicesData errorMechanical engineering

The invention discloses a vehicle brake pad surface total run-out detection device which comprises a supporting seat, a brake simulation device, a distance measuring sensor moving device, a V-shaped block fastening device and a lead screw transmission device. A to-be-tested axle is fixed on the supporting seat, the brake simulation device, the V-shaped block fastening device and the lead screw transmission device are all fixed on the to-be-tested axle, and the distance measuring sensor moving device is fixed on the V-shaped block fastening device. The turntable drives the lead screw to rotatethrough driving of the turntable through arrangement of the lead screw transmission device and the sensor sliding device so that synchronization of rotation and movement of the sensor is realized, thetrack stability of the sensor is ensured, the operation is simple and the data error is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Multipole ion guide ion trap mass spectrometry with MS/MSN analysis

InactiveUS8598519B2Rapid mass analysis capabilityTrajectory stabilizationStability-of-path spectrometersTime-of-flight spectrometersIon trap mass spectrometryMass analyzer

A method includes directing ions from an atmospheric pressure ion source to a first ion guide; directing ions in the first ion guide to a second ion guide, the second ion guide being a multipole ion guide extending along an axis; periodically directing ions along the axis; receiving at least some of the ions in a time-of-flight analyzer; accelerating the ions in the time-of-flight mass analyzer orthogonal to the axis; and detecting the accelerated ions.

Owner:PERKINELMER HEALTH SCIENCES INC

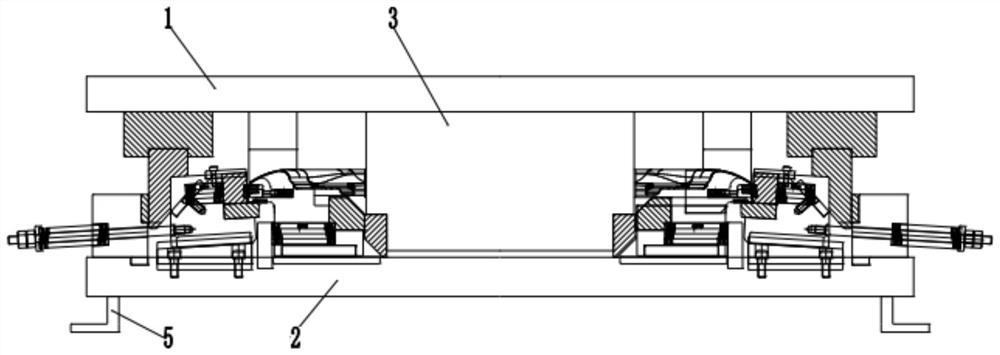

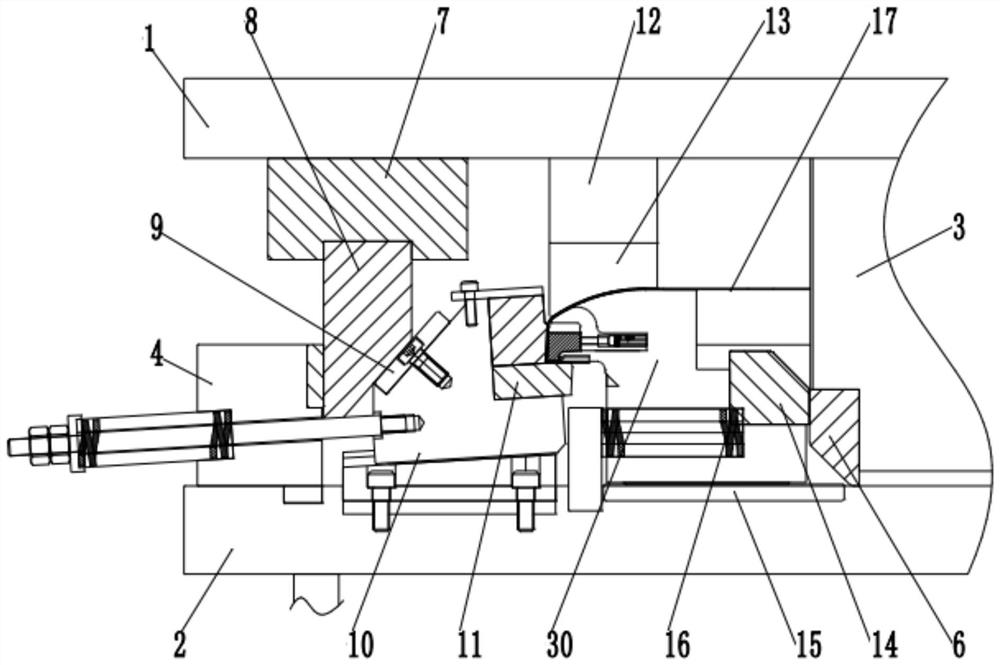

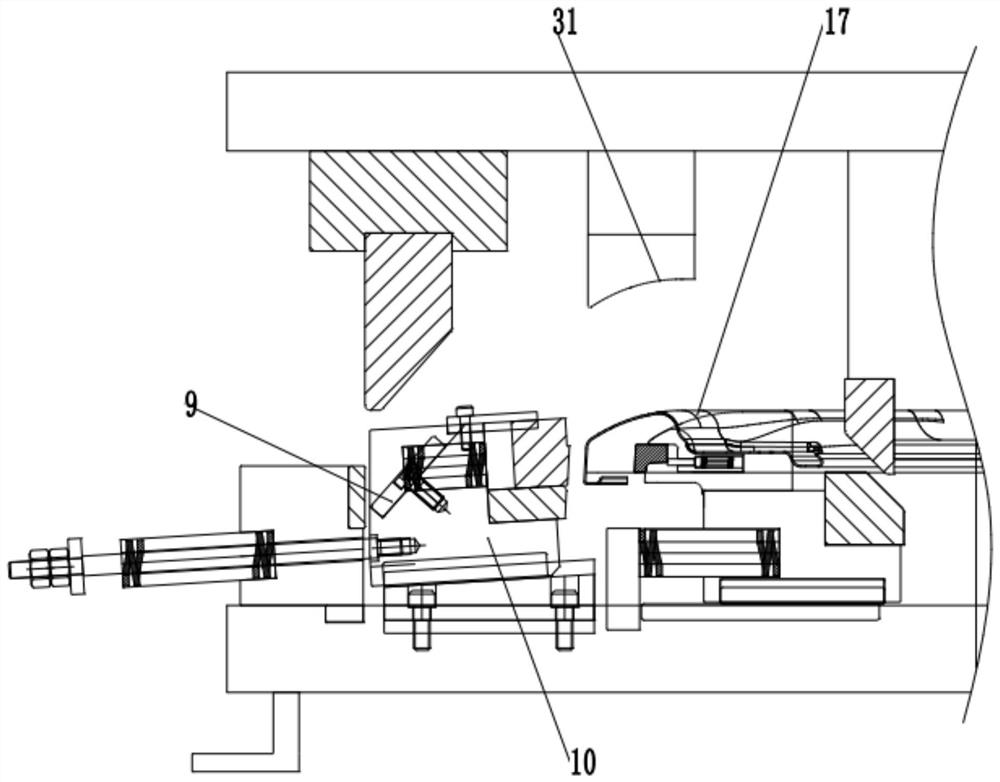

Side bending sliding block demolding mechanism

PendingCN114273545AEasy to demouldIncrease productivityEjection devicesMold removalIndustrial engineering

The invention relates to the technical field of molds, in particular to a side bending slider demolding mechanism which comprises an upper mold, a bottom plate is arranged at the bottom of the upper mold, a bending male mold is slidably connected to the top of the bottom plate, a second opening inclined block is connected to the outer wall of one side of the bending male mold through a bolt, and a push block is slidably connected to the top of the bottom plate. The outer wall of one side of the push block is connected with a side face female die through a bolt, the outer wall of the bottom of the upper die is connected with a connecting column through a bolt, the outer walls of the two sides of the connecting column are connected with first opening inclined blocks through bolts, the first opening inclined blocks are matched with the second opening inclined blocks, and the outer walls of the two sides of the push block are connected with extrusion inclined plates through bolts. According to the side bending mold, the side bending boss is bent under the combined action of the side pressing plate, the demolding sliding block and the side female mold, so that in the mold opening process, a workpiece body can be ejected out through the elastic force of a fourth spring, and then the effect that demolding is convenient when a product is laterally bent is achieved; and the production efficiency of products is greatly improved.

Owner:滁州市艾德模具设备有限公司

Vehicle brake drum surface total run-out detection device

ActiveCN111141242ATrajectory stabilizationEasy to operateMeasurement devicesData errorMechanical engineering

The invention discloses a vehicle brake drum surface total run-out detection device, which comprises a base, a fixed seat, a mandrel, a brake drum fixing device, a V-shaped block fastening device, a distance measuring sensor rotating device and a distance measuring sensor moving device, wherein the fixed seat is arranged on the base, the mandrel is arranged on the fixed seat, the brake drum fixingdevice, the V-shaped block fastening device and the distance measuring sensor rotating device are all arranged on the mandrel, and the distance measuring sensor moving device is arranged on the distance measuring sensor rotating device. By arranging the distance measuring sensor moving device and the distance measuring sensor rotating device, synchronization of rotation and movement of the sensoris achieved, the track of the sensor is ensured to be stable, operation is easy, and data errors are reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

String-up switching mechanism of winding machine

The invention provides a string-up switching mechanism of a winding machine, and relates to the field of textile machinery. The string-up switching mechanism comprises a move-down silk plate and a shoveling plate, wherein a slideway is arranged on the shoveling plate, and a sliding head matched with the slideway is arranged on the move-down silk plate; a groove for hooking and pulling a silk beam is formed in one side of the move-down silk plate; and a bending way opposite to the one side of the groove is arranged at the slideway. The string-up switching mechanism of the winding machine has high string-up switching success rate, the waste silk quantity can be greatly reduced, and meanwhile the product quality is increased. As the improvement cost is low, the string-up switching mechanism is also suitable for large-range popularization and application.

Owner:JIANGSU CHALLEN FIBER S&T

Rectilinear vibrating screen for two groups of split seat-type vibration exciters

The invention relates to a rectilinear vibrating screen for two groups of split seat-type vibration exciters, which belongs to the field of vibrating screening machines. The invention aims to solve the problem of unfavorable stress condition at the screen frame of the rectilinear vibrating screen, and the problem of poor self-synchronizing effect of the two-shaft vibration exciter. The screen frame of the vibrating screen is provided with two vibration exciter mounting beams with a large space, each mounting beam is provided with one group of single-shaft seat-type vibration exciters, the rotation directions of the main shafts of the two single-shaft seat-type vibration exciters are opposite, and the two single-shaft seat-type vibration exciters are respectively connected with motor transmission gears positioned on one or two sides of the screen box; the main shaft of the vibration exciter is installed on the cabinet of vibration exciter through two bearings, and two eccentric blocks are installed on both ends of the main shaft; the two corresponding single-shaft seat-type vibration exciters are assembled together through a bearing beam; and the end of the bearing beam is providedwith a wedge-shaped adjusting mechanism capable of fine adjusting the joint gap of the two single-shaft seat-type vibration exciters. In the invention, the vibration exciters can be arranged at a wide space; and the invention has the characteristics of reasonable structure, good synchronizing effect, convenient installation, maintenance and adjustment of the vibration exciters, and the like. The invention is suitable for large rectilinear vibrating screens in various screening operations.

Owner:鞍山鞍重矿山机械有限公司

Magnetic shielding system for electron beam welding

ActiveCN108746975BTrajectory stabilizationImprove welding precisionElectron beam welding apparatusElectron beam machiningParticle physics

The invention belongs to the field of welding, and particularly relates to a magnetic shielding system for electron beam welding. The magnetic shielding system comprises a detecting portion, a shielding cover body and a control portion. The structure of a shielding cover can be adjusted according to the complexity degree of electron beam processing and the intensity of an environmental magnetic field, and an electric ejector rod is controlled to enable inner and outer layer silicon steel sheets to be nested and combined into a single layer structure or a multi-layer structure, so that different shielding requirements are met, a stable trajectory is ensured during electron beam processing, and welding precision is high.

Owner:JIANGSU JINGYI ELECTRICAL APPLICANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com