Flotation gathering device and screening method for microplastics

A screening method and technology for microplastics, applied in the field of micro-pollutant environmental detection, can solve the problems of investigation and routine monitoring that cannot meet the needs of large-scale and large sample size, sampling, sorting methods, lack of norms and standards, flotation, separation and The measurement method is inefficient and other problems, to achieve the effect of improving the hydrodynamic environment, simple and easy operation and cleaning, and increasing the surface area of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below through specific examples.

[0015] The basic principle of the present invention is based on the fact that the surfactant can change the difference in the adhesion characteristics of bubbles on the hydrophilic and hydrophobic materials, and the high-density flotation solution can improve the separation effect on high-density microplastics.

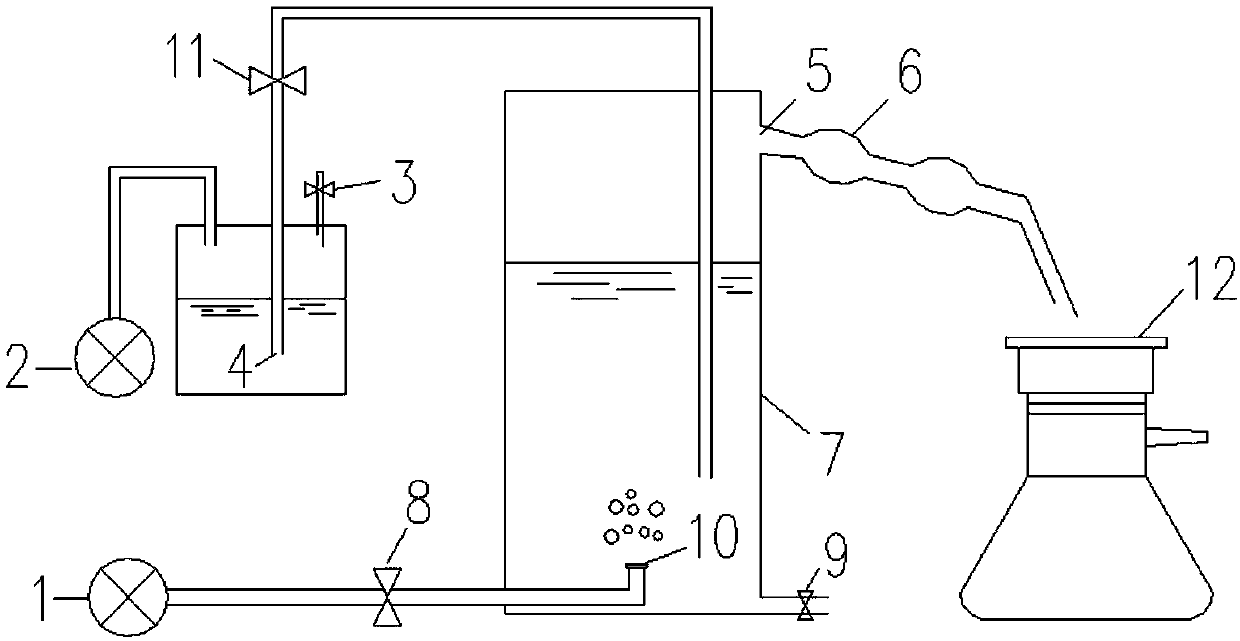

[0016] The flotation, enrichment and screening device for microplastics of the present invention includes a flotation liquid reservoir 4 and a separation pipe 7, and the flotation liquid reservoir 4 and the separation pipe 7 are submerged by an outflow valve 11. The outlet of a pneumatic pump 2 is connected with the inlet of the gas pipe, and the outlet of the gas pipe is aligned with the mixed solution in the flotation liquid reservoir 4, and the flotation liquid storage An air release valve 3 is installed on the top wall of the device 4. The outlet o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com