Finishing agent composition for flax fabrics and processing method of flax easy-care shirt

A processing method and finishing agent technology, applied in shirts, textiles, papermaking, wrinkle-removing and flattening equipment, etc., can solve the problems of reduced strength and wear resistance, and reduced cracks, etc., to achieve easy care and strong air permeability , Overcoming the hard feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

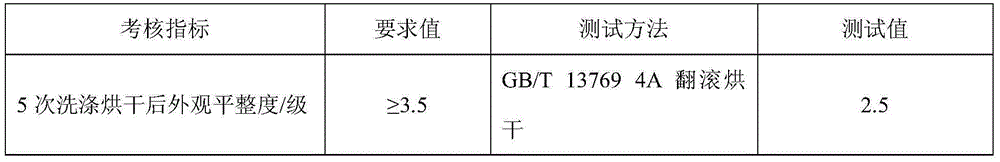

[0018] Embodiment 1: the shirt ready-made garment fabric that present embodiment selects is hemp yarn and cotton yarn interweaving shirt fabric, warp direction all cotton, weft direction whole linen yarn-dyed fabric, hemp content is 56%. In parts by weight, the finishing agent composition used contains: 140g of FixapretF-ECO, 15g of NT-H420, 20g of Nano-PU, 30g of AP-NP40, 30g of HI-SOFT, 60g of SIS, 2g of JFC , 17g MgCl 2 , 5g anti-cracking agent SSG300. First, pre-wash and dry the finished shirt; then apply the above-mentioned finishing agent composition evenly to the pre-washed and dried whole shirt through an automatic spraying machine, so that the liquid-carrying rate of the shirt is 80%; Bake the shirt, the liquid retention rate after pre-drying is about 30%; then press each part of the shirt on the pressing machine at 160°C for 40s through the mold, and the pressure applied during pressing is 0.5Kg / cm 2 ; The pressed shirt was baked in an oven at 120°C for 8 minutes; ...

Embodiment 2

[0020] Embodiment 2: The shirt ready-to-wear fabric selected in this embodiment is full hemp class woven shirt fabric, pure hemp class jacquard cloth. In parts by weight, the finishing agent composition used contains: 160g of NT-R521, 10g of NT-H420, 50g of Nano-PU, 40g of AP-NP40, 30g of PEP, 60g of TEXILONEL70, 2g of JFC, 19g MgCl 2 , 6g of anti-slipping agent SSG300. First, pre-wash and dry the finished shirt; then apply the above finishing agent composition evenly to the pre-washed and dried whole shirt through an automatic sprayer, so that the liquid-carrying rate of the shirt is 65%; Bake the shirt, the liquid retention rate after pre-drying is about 50%; then press each part of the shirt on the pressing machine at 160°C for 40s through the mold, and the pressure applied during pressing is 0.5Kg / cm 2; The pressed shirt was baked in an oven at 120°C for 8 minutes; the baked shirt was cooled, placed in a washing solution with a JFC content of 2g / L, and washed with indust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com