Tomato sauce and preparation method thereof

A production method and technology for ketchup, which are applied in the directions of food ingredients as emulsifiers, food ingredients as viscosity modifiers, and food ingredients as taste improvers, etc., can solve the problems of tomato paste taste influence, low dietary fiber and protein content, etc. , to achieve the effect of overcoming roughness, improving taste and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

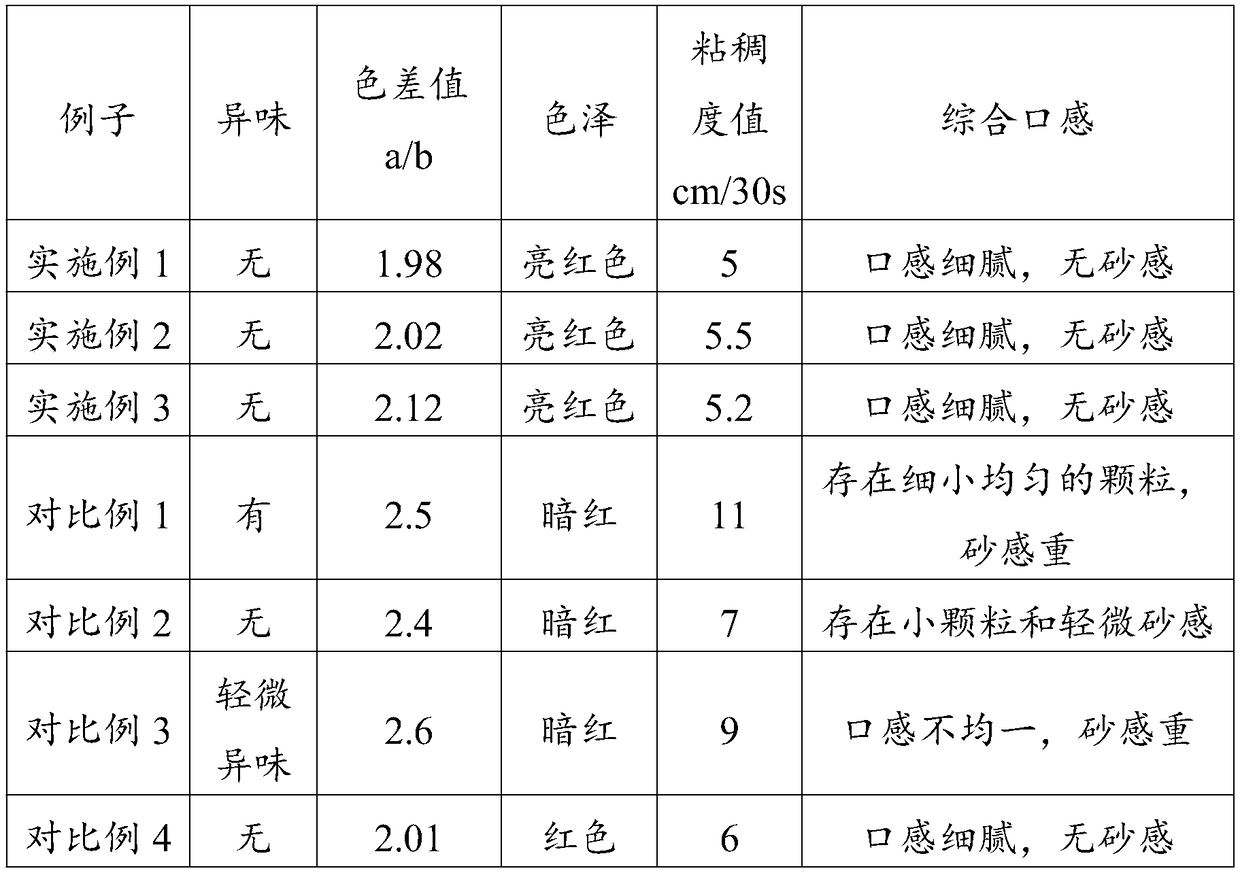

Examples

Embodiment 1

[0020] A tomato paste is composed of the following components in terms of mass percentage: 2% soybean protein isolate, 1% soybean dietary fiber, 2% corn germ oil, 10% sugar, 0.6% salt, 1% starch, raw tomato sauce 20%, the rest is water.

[0021] The preparation method of described tomato paste, comprises the steps:

[0022] 1) dry mixing the soybean dietary fiber and vegetable protein;

[0023] 2) Preparation of emulsified fiber slurry: Disperse the mixed soybean dietary fiber and vegetable protein into water at 40°C at a uniform speed, and stir while dispersing. The stirring speed is 700r / min. After the soybean dietary fiber and vegetable protein are added, the Add vegetable oil at a stirring speed of 700r / min, pre-emulsify at 3000r / min for 3min, emulsify at 8000r / min for 7min, and prepare emulsified fiber pulp for later use;

[0024] 3) Mixing: mix the emulsified fiber pulp with the original tomato sauce, water, sugar, and salt evenly, add starch, process it with a high-sp...

Embodiment 2

[0027] A tomato paste is composed of the following components in terms of mass percentage: 3% soybean protein isolate, 1% dietary fiber, 1% corn germ oil, 8% sugar, 1% salt, 1% starch, and 25% tomato puree %, the rest is water.

[0028] The preparation method of described tomato paste, comprises the steps:

[0029] 1) dry mixing the dietary fiber and vegetable protein;

[0030] 2) Preparation of emulsified fiber slurry: Disperse the above-mentioned mixed dietary fiber and vegetable protein into water at 40°C at a uniform speed, and stir while dispersing. The stirring speed is 1000r / min. Add vegetable oil under the stirring speed of / min, pre-emulsify for 3min at 5000r / min, emulsify for 1min at 10000r / min, and prepare emulsified fiber pulp for subsequent use;

[0031] 3) Mixing: Mix the above-mentioned emulsified fiber pulp with tomato original sauce, water, sugar, and salt evenly, add starch, process it with a high-speed shearing machine at 10,000r / min for 8 minutes, and put...

Embodiment 3

[0034] A tomato paste is composed of the following components in terms of mass percentage: 3% soybean protein isolate, 3% dietary fiber, 2.5% corn germ oil, 5% sugar, 1% salt, 0.5% starch, 30% tomato puree %, the rest is water.

[0035] The preparation method of described tomato paste, comprises the steps:

[0036] 1) dry-mixing the above-mentioned dietary fiber and vegetable protein;

[0037] 2) Preparation of emulsified fiber slurry: Disperse the above-mentioned mixed dietary fiber and vegetable protein into water at 40°C at a uniform speed, and stir while dispersing. The stirring speed is 800r / min. Add vegetable oil under the stirring speed of / min, pre-emulsify for 3min at 3000r / min, emulsify for 10min at 5000r / min, and prepare emulsified fiber pulp for subsequent use;

[0038] 3) Mixing: Mix the above-mentioned emulsified fiber pulp with tomato original sauce, water, sugar, and salt evenly, add starch, process it with a high-speed shearing machine at 5000r / min for 5 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com