Formaldehydeless permanent press finishing agent for fabric and preparation method and application thereof

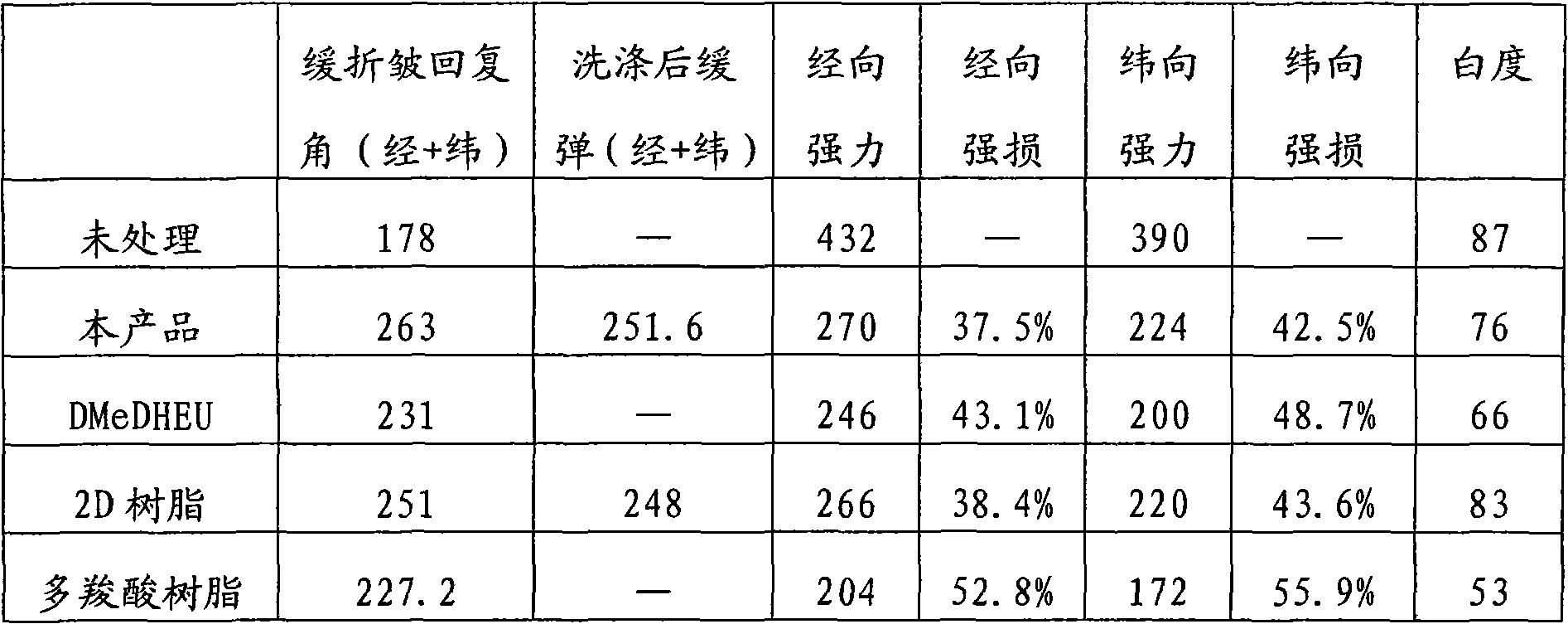

A non-iron finishing and fabric technology, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems that cannot be popularized and applied, the anti-wrinkle effect is not as good as 2D resin, and the cost is low. , the effect of small strength loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] A, preparation of initiator aqueous solution: 0.2g ammonium persulfate is added water 15g to make initiator aqueous solution;

[0092] B. Synthesis: Add acrylamide 27.5g, glyoxal 12.5g, deionized water 44.0g, phthalic dipotassium anhydride 0.3g and 98(V / V)% concentrated sulfuric acid 0.25g, feed nitrogen, heat up to 50-70°C for 3-5 hours, cool down to about 40°C after reaction, take out 40-60g, heat up to 60-80°C, add sodium bisulfite 0.3g, then add 5-8g of initiator aqueous solution to initiate, after initiation, drop the remaining reactant and initiator aqueous solution at 75-90°C, control the time of dropping within 1-2 hours, add 0.02g after dropping Chain terminator - p-hydroxyanisole, and react at 75-90°C for 1-5 hours to obtain the desired product, which can be used for non-ironing finishing of cellulose fibers to improve the elasticity of fabrics.

Embodiment 2

[0094] A, the preparation of initiator aqueous solution: 0.15g ammonium persulfate is added water 15g to make initiator aqueous solution;

[0095] B. Synthesis: Add acrylamide 21.3g, glyoxal 8.7g, deionized water 54.2g, phthalic anhydride 0.25g and 98(V / V) % concentrated sulfuric acid 0.20g, feed nitrogen, heat up to 50-70°C and react for 3-5 hours, cool down to about 40°C after reaction, take out 40-60g, heat up to 60-80°C, add sodium bisulfite 0.2g, then add 5-8g of initiator aqueous solution to initiate, after initiation, drop the remaining reactants and initiator aqueous solution at 75-90°C, control the drop time within 1-2 hours, add 0.01g after the dropwise addition Chain terminator-p-hydroxyanisole, react at 75-90°C for 1-5 hours, cool down to 40°C to obtain the desired product, which can be used for non-ironing finishing of cellulose fibers to improve the elasticity of fabrics.

Embodiment 3

[0097] A, the preparation of initiator aqueous solution: 0.5g potassium persulfate is added water 15g to make initiator aqueous solution;

[0098] B. Synthesis: Add acrylamide 33.8g, glyoxal 16.2g, deionized water 33.2g, acetic anhydride 0.4g and 98 (V / V)% respectively in a four-necked flask equipped with a stirrer, a thermometer and a condenser Concentrated sulfuric acid 0.35g, feed nitrogen, heat up to 50-70°C and react for 3-5 hours, cool down to about 40°C after reaction, take out 40-60g, heat up to 60-80°C, add 0.5g of sodium bisulfite, Then add 5-8g of initiator aqueous solution to initiate, after initiation, drop the remaining reactants and initiator aqueous solution at 75-90°C, control the drop time within 1-2 hours, add 0.02g chain terminator after the dropwise addition - Hydroquinone, react at 75-90°C for 1-5 hours, cool down to 40°C and add 25g of deionized water to obtain the desired product, which can be used as an auxiliary agent for acrylate resins to improve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com