Formaldehyde-removal odor-removal double effect catalyst

A deodorant and catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalyst, dispersed particle separation, physical/chemical process catalyst, etc., can solve the problems of short action time, high cost, poor adhesion, etc. To achieve the effect of improving freshness and improving fixed energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

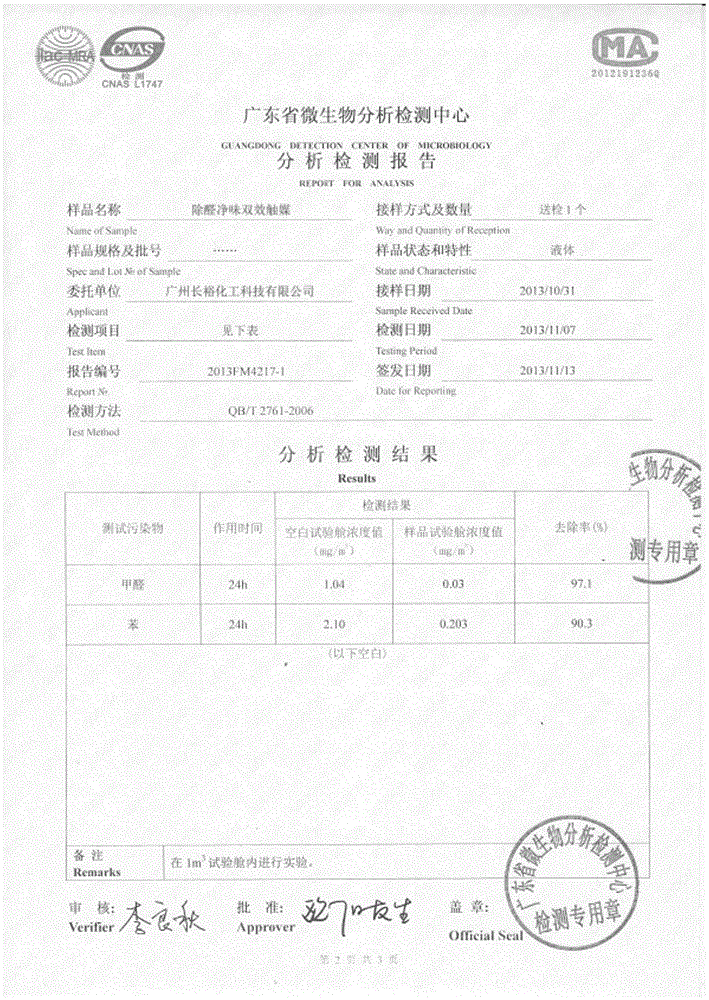

[0032] Dissolve 5g of water-soluble chitosan quaternary ammonium salt in 910g of pure water, then add 50g of ethylene urea to the above mixture and stir evenly, and finally add 10g of eucalyptus oil, 5g of azone, and 20g of nano-anion powder in turn, and fully stir That is, a double-effect catalyst for removing aldehyde and deodorizing is obtained, which is used for removing low-pollution formaldehyde, and the removal rate of formaldehyde reaches over 90% within 24 hours.

[0033] For specific test results, see the attached Figure 1-3 .

Embodiment 2

[0035] Dissolve 10g of water-soluble chitosan quaternary ammonium salt in 860g of pure water, then add 80g of ethylene urea to the above mixture and stir evenly, and finally add 20g of eucalyptus oil, 10g of azone, and 20g of nano-anion powder in turn, and fully stir That is, a double-effect catalyst for removing aldehyde and deodorizing is obtained, which is used for removing low-pollution formaldehyde, and the removal rate of formaldehyde reaches over 90% within 24 hours.

Embodiment 3

[0037] Dissolve 8g of water-soluble chitosan quaternary ammonium salt in 854g of pure water, then add 95g of ethylene urea to the above mixture and stir evenly, and finally add 15g of eucalyptus oil, 8g of azone, and 20g of nano-anion powder in turn, and fully stir That is, a double-effect catalyst for removing aldehyde and deodorizing is obtained, which is used for removing low-pollution formaldehyde, and the removal rate of formaldehyde reaches over 90% within 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com