One-step dyeing method of porous cellulose microspheres-modified dyed cotton blended fabric

A technology of porous cellulose and cellulose microspheres, which is applied in the field of one-step dyeing of cotton blended fabrics, can solve the problems of difficult treatment, large sewage discharge, and increased friction frequency of fabrics, and achieve good uniformity of dyeing and high dyeing efficiency. The effect of high efficiency and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

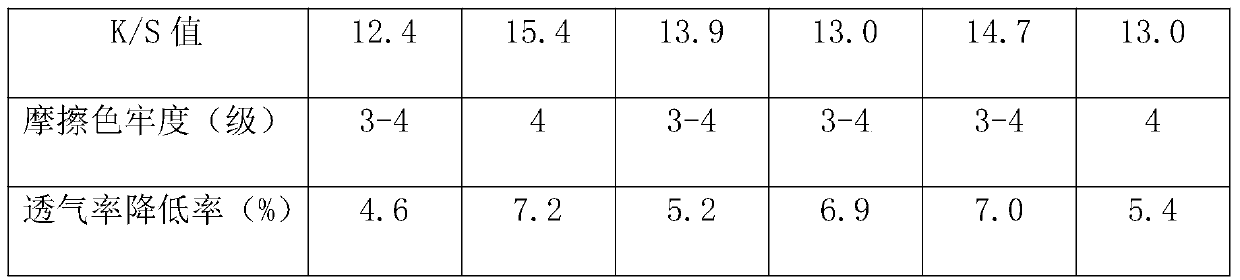

Embodiment 1

[0027] (1) Add cetyltrimethylammonium chloride to the sodium hydroxide solution and mix well to obtain an alkaline pretreatment solution. The content of sodium hydroxide in the alkaline pretreatment solution is 10%. The content of trimethylammonium chloride is 3%.

[0028] (2) The polyester-cotton blended fabric is immersed in an alkaline pretreatment solution, paddled at 35°C with a crease rate of 70%, washed and dried to obtain a pretreated polyester-cotton blended fabric.

[0029] (3) Add the cellulose fiber to the formic acid and hydrochloric acid mixture with a volume ratio of 2:1, heat and stir to dissolve at a frequency of 500r / min at 70°C for 4h, cool to room temperature, adjust the pH to neutral, and disperse In the aqueous solution, a 25 mg / mL methyl esterified cellulose crystallite solution was obtained.

[0030] (4) Drop the methyl esterified cellulose microcrystal solution into the acid regeneration solution, after solidification, take out the cellulose nano hydrogel sp...

Embodiment 2

[0034] (1) Add cetyltrimethylammonium chloride to the sodium hydroxide solution and mix well to obtain an alkaline pretreatment solution. The content of sodium hydroxide in the alkaline pretreatment solution is 15%. The content of trimethylammonium chloride is 5%.

[0035] (2) The polyester-cotton blended fabric is immersed in an alkaline pretreatment solution, paddled at 40°C with a crease rate of 75%, washed and dried to obtain a pretreated polyester-cotton blended fabric.

[0036] (3) Add the cellulose fiber to the formic acid and hydrochloric acid mixture with a volume ratio of 3:1, heat and stir to dissolve at 80°C at a frequency of 800r / min for 6h, cool to room temperature, adjust the pH value to neutral, and disperse In the aqueous solution, a 30 mg / mL methyl esterified cellulose crystallite solution was obtained.

[0037] (4) Drop the methyl esterified cellulose microcrystal solution into the acid regeneration solution, after solidification, take out the cellulose nano hydro...

Embodiment 3

[0041] (1) Add cetyltrimethylammonium chloride to the sodium hydroxide solution and mix well to obtain an alkaline pretreatment solution, wherein the content of sodium hydroxide in the alkaline pretreatment solution is 13%, hexadecane The content of trimethylammonium chloride is 4%.

[0042] (2) The polyester-cotton blended fabric is immersed in an alkaline pretreatment solution, paddled at 38°C with a crease rate of 72%, washed and dried to obtain a pretreated polyester-cotton blended fabric.

[0043] (3) Add the cellulose fiber to the formic acid and hydrochloric acid mixture with a volume ratio of 2.3:1, heat and stir to dissolve at a frequency of 600r / min at 75°C for 5h, cool to room temperature, adjust the pH to neutral, and disperse In the aqueous solution, 28 mg / mL of methyl esterified cellulose crystallite solution was obtained.

[0044] (4) Drop the methyl esterified cellulose microcrystal solution into the acid regeneration solution, after solidification, take out the cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com