Process for synthesizing polyethylene glycol (PEG) phase change thermal insulation material

A phase change thermal insulation material and process technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of phase change material loss, increase in production costs, loss of material phase change thermal insulation performance, etc., to achieve strong hygroscopicity, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

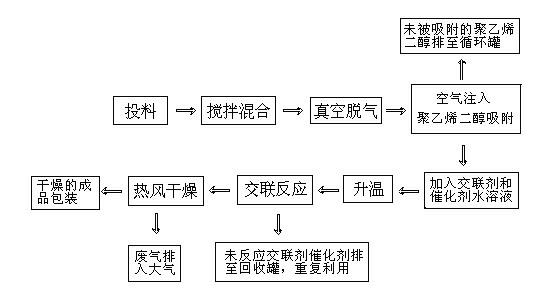

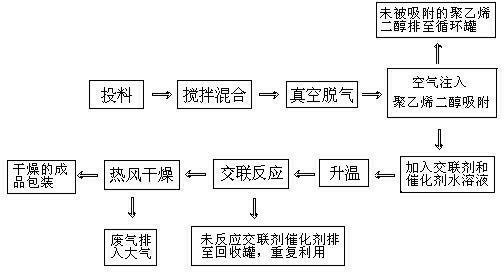

Method used

Image

Examples

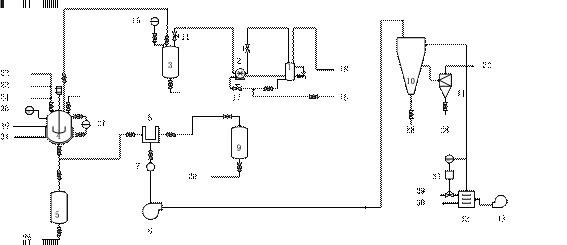

Embodiment Construction

[0010] 160 kilograms of expanded perlite powder (particle size 0.15.mm-1.18mm) and about 500 kilograms of PEG 600 were added to a 3 cubic meter vacuum reactor 1, added at room temperature and stirred at a rotational speed of about 80 r / min. Adsorption of PEG 600 by expanded perlite powder is done under vacuum. The vacuum degree of the reactor system is composed of a vacuum system composed of a water ring vacuum pump 2, a vacuum buffer tank 3 and a water ring vacuum pump vapor-liquid separation tank 1. The degree of vacuum in the reactor can be adjusted by the opening degree of the shut-off valve 14 on the vacuum buffer tank 3 . The pressure of the system can be read from the vacuum pressure gauge 15 on the vacuum buffer tank 3 . The water for vacuum sealing of the water ring vacuum pump 2 is provided by the process water pipeline 16 , and the water supply amount can be adjusted by the shut-off valve 17 . The liquid level of the water ring vacuum pump vapor-liquid separation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com