Digesting assistant in use for making paper

A cooking aid, molecular formula technology, applied in papermaking, textile and papermaking, pulping of cellulose raw materials, etc., can solve the problems affecting the quality and yield of pulp, long time for lignin decomposition and dissolution, slow penetration, etc. Good emulsification and diffusivity, reducing redox effects and improving whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

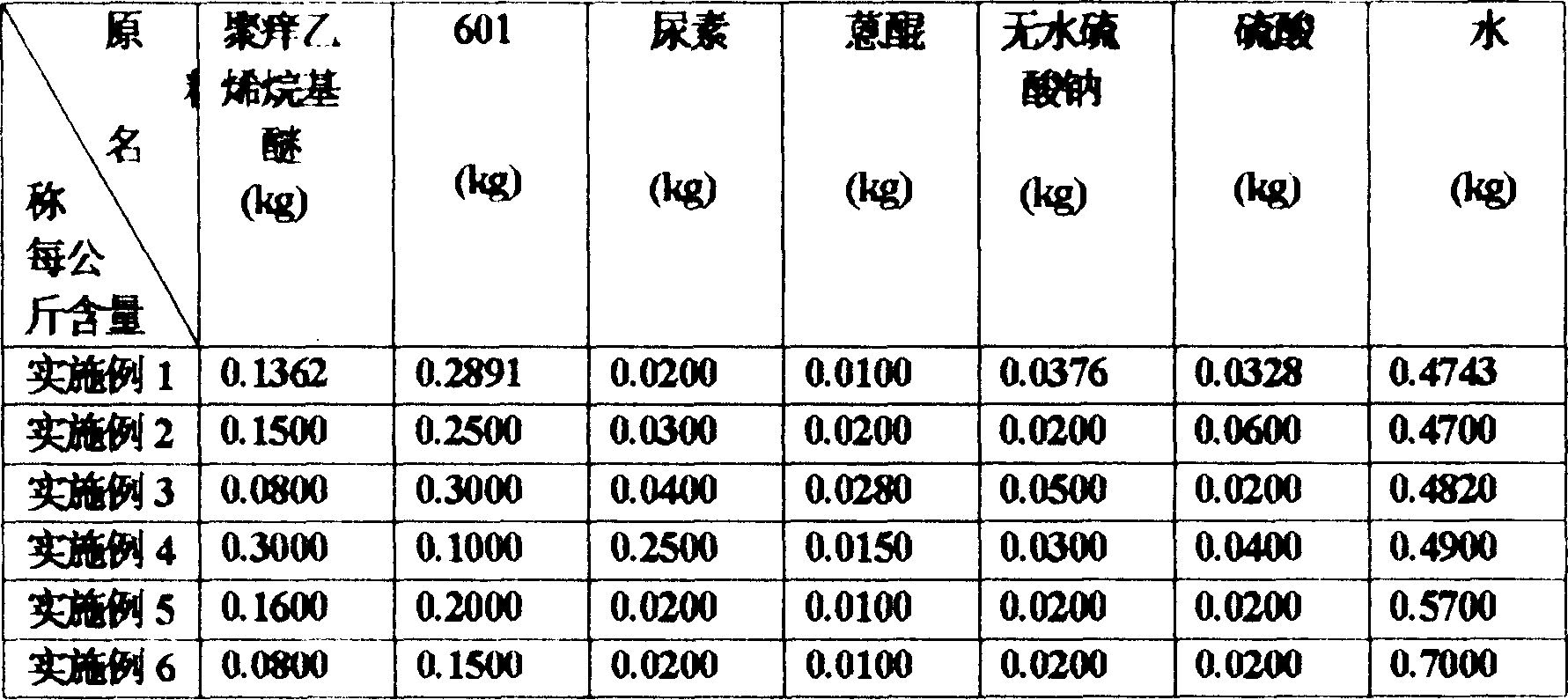

[0013] The specific embodiment, manufacturing process and effect of the present invention will be further described in conjunction with Table 1 below.

[0014] The papermaking cooking aid of the present invention contains the following components in every kilogram of cooking aid:

[0015] Polyoxyethylene alkyl ether molecular formula C 12-14 h 25-29 O(CH 2 CH 2 O) 3 H 0.08-0.3Kg

[0016] Sodium alkyl sulfonate molecular formula C 12-16 h 25-33 SO 3 N a 0.1-0.4kg

[0017] Urea 0.02-0.04Kg

[0018] Anthraquinone 0.01-0.03Kg

[0019] Anhydrous sodium sulfate 0.02-0.05Kg

[0020] Sulfuric acid (content 93-98%) 0.02-0.06kg

[0021] Water 0.4-0.7Kg

[0022] Production technology of the present invention:

[0023] 1. Prepare materials according to the ratio of raw materials in Table 1:

[0024] 2. Add water to the reaction kettle, raise the temperature slowly, start stirring, pour the above raw materials into the reaction kettle in sequence, heat up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com