A soluble antiscale wax control ball

A soluble and anti-wax technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of heavy workload, affecting the operation safety of gathering and transportation pipelines, and increasing the back pressure of pipelines, and achieves good wax removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0030] Adopt the formula ratio as shown in table 1 to manufacture TT-166 soluble anti-wax anti-fouling ball, wherein TT-166 is the inventor's own numbering to anti-wax anti-fouling ball, those skilled in the art can also adopt any other numbers. The preparation of TT-166 soluble anti-wax and anti-fouling balls is carried out according to the following steps.

[0031] 1. React in a high-temperature, high-pressure reactor at a constant temperature of 90°C for 3 hours to prepare a liquid mixed wax and scale inhibitor, neutralize and cool to room temperature to obtain wax and scale inhibitor crystals.

[0032] 2. After being dehydrated by a centrifuge, dried by a vacuum dryer, and pulverized by a pulverizer, it is ready for use.

[0033] 3. The binder will be mixed with the crushed anti-scaling agent crystal, heated and extruded to form a regular spherical body, and cooled to obtain TT-166 soluble anti-wax and anti-scaling ball.

[0034] Table 1

[0035] serial number ...

Embodiment 5-7

[0061] Examples 5-7 are the same as the method for preparing the anti-wax and anti-fouling balls described in Example 1, except for the compounding ratio. The specific compounding ratio is shown in Table 5-6.

[0062] table 5

[0063] serial number

[0064] Wherein, the weight ratio composition (A:B:C) of the compound surfactant in Table 5 is 1:1:2; the weight composition of the wax remover is shown in Table 6.

[0065] Table 6

[0066] serial number

[0067] The anti-scaling and anti-wax balls of Examples 5-7 were used to test the amount of wax deposited and the anti-wax rate. The results are shown in Table 7.

[0068] Table 7

[0069] serial number

[0070] It can be seen from Table 7 that the different ratios of EVA and LDPE affect the wax-repelling effect of the system. Wherein, the compounding dosage of fixed surfactant K is about 30%. In Table 7, the amount of the anti-wax and anti-fouling balls is 40 mg / L, and the amount of wax dep...

Embodiment 8-11

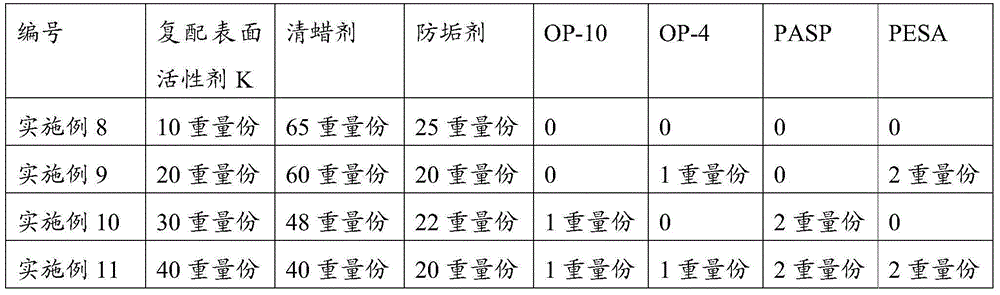

[0072] The weight compositions of Examples 8-11 are shown in Table 8.

[0073] Table 8

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com