Preparation method of hydroxylamine sulfate

A technology of hydroxylamine sulfate and sulfuric acid, which is applied in the chemical industry, can solve the problems of excessive acid in reactants, high energy consumption of distilled water, waste of raw materials, etc., and achieve the effects of avoiding side reactions, increasing the utilization rate of raw materials, and improving the total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

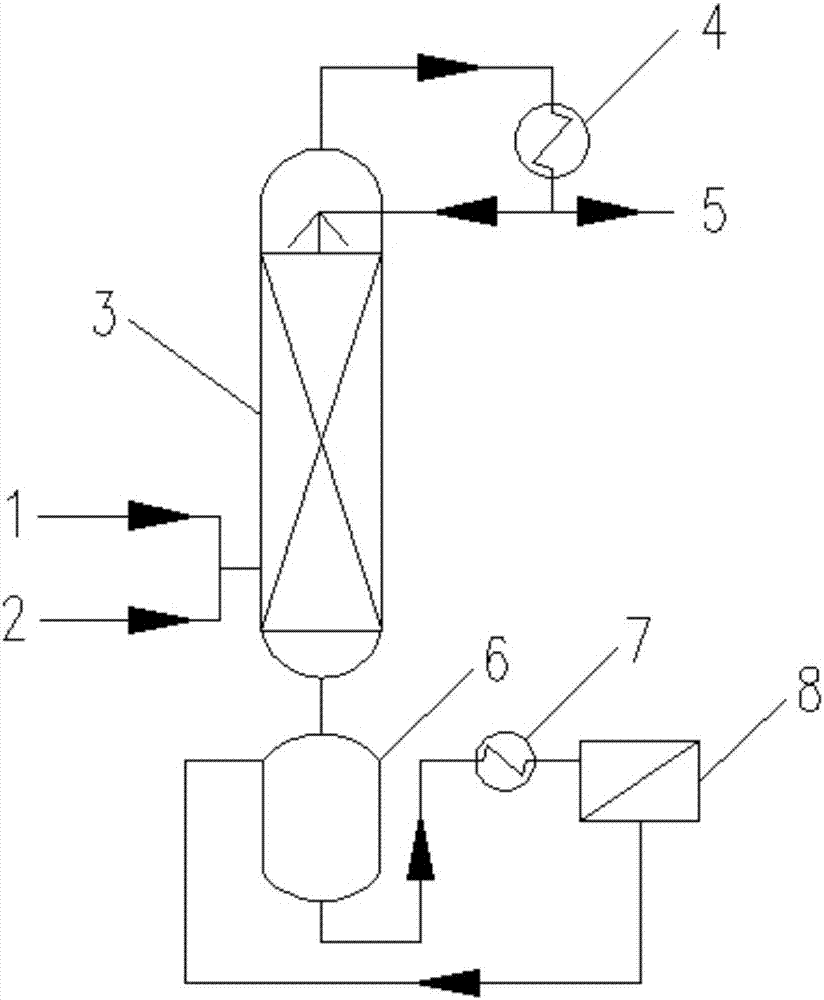

Image

Examples

Embodiment 1

[0034] Butanone oxime, 50wt% sulfuric acid aqueous solution according to butanone oxime and H 2 SO 4 The molar ratio is 1:0.5 (the molar ratio of butanone oxime and the aqueous sulfuric acid solution is 0.367:1). Weigh 435.6g and 490g respectively, add them to the reaction kettle for reactive distillation, and control the pressure of the reactive distillation system in the reactor to 0.028-0.055MPa, the temperature of the tower bottom is 80-85°C, the top reflux ratio is 0-6, and the butanone distilled from the top of the rectification tower is removed in time. After four hours of reactive distillation, take a sample from the tower kettle periodically (for example, every hour), and titrate the concentrations of sulfuric acid and hydroxylamine sulfate therein. After reacting for seven hours, when the hydroxylamine sulfate concentration was 5mol / L, the reaction solution was transferred to a crystallization tank for crystallization. The crystals were filtered twice, and the crys...

Embodiment 2

[0036] Butanone oxime, 55wt% sulfuric acid aqueous solution according to butanone oxime and H 2 SO 4 The molar ratio is 1:0.5 (the molar ratio of butanone oxime and sulfuric acid aqueous solution is 0.449:1). Weigh 348.48g and 356.36g respectively, add them to the reaction kettle for reactive distillation, and control the pressure of the reactive distillation system in the tower reactor 0.030-0.055MPa, the temperature of the tower bottom is 80-85°C, the top reflux ratio is 0-6, and the butanone distilled from the top of the rectification tower is removed in time. After four hours of reactive distillation, take a sample from the tower kettle periodically (for example, every hour), and titrate the concentrations of sulfuric acid and hydroxylamine sulfate therein. After seven hours of reaction, when the concentration of hydroxylamine sulfate was 5 mol / L, the temperature of the reaction system was lowered to 50° C. and the reaction solution was transferred to a crystallization ta...

Embodiment 3

[0038] Butanone oxime, 60wt% sulfuric acid aqueous solution according to butanone oxime and H 2 SO 4 The molar ratio is 1:0.5 (the molar ratio of butanone oxime and sulfuric acid aqueous solution is 0.551:1). Weigh 435.6g and 408.33g respectively, add them to the reaction kettle for reactive distillation, and control the pressure of the reaction distillation system in the tower reactor 0.025 ~ 0.055MPa, the temperature of the tower bottom is 80 ~ 90 ° C, the top reflux ratio is 0 ~ 6, and the butanone distilled from the top of the rectification tower is removed in time. After four hours of reactive distillation, take a sample from the tower kettle periodically (for example, every hour), and titrate the concentrations of sulfuric acid and hydroxylamine sulfate therein. After reacting for seven hours, when the hydroxylamine sulfate concentration was 4mol / L, the reaction solution was transferred to a crystallization tank for crystallization. The crystals were filtered twice, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com