New synthesis method of blocking agent for isocyanate-based cross-linking agents

A technology of cross-linking agent and sealing agent, which is applied in the synthesis field of sealing agent, can solve the problems of large amount of waste water and waste gas pollutants, unsuitable for industrial production, and high production cost, so as to save equipment investment, increase production rate, and reduce usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

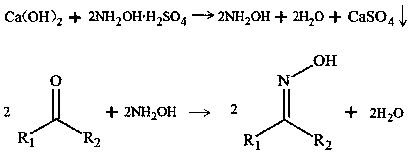

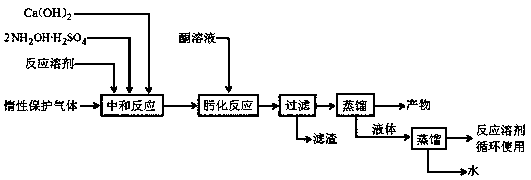

Method used

Image

Examples

Embodiment 1

[0016] In a 500mL flask equipped with a stirrer, dropping funnel, thermometer, and condenser, add calcium hydroxide, hydroxylamine sulfate and reaction solvent with a molar ratio of 1:0.1:2.00. The mass and volume are 111.00g and 24.60 respectively. g, 135.00g, and slowly fill the inert protective gas, stir the reaction raw materials, heat up, and after the temperature rises to the reaction temperature, according to the molar ratio of calcium hydroxide to methyl ethyl ketone 1:0.1, the starting mass is 36.00g, the concentration It is a 30% methyl ethyl ketone-reaction solvent solution. It takes 1 hour to drip. After the dripping is completed, continue to stir for 5 hours, control the temperature between 40 and 100℃. After the reaction, let stand for 1 to 5 hours and filter the reaction system. , Distill the filtrate to obtain the reaction product.

[0017] The analysis results showed that the conversion rate of ketone was 95.69%, and the selectivity of oxime was 99.56%.

[0018] ...

Embodiment 2

[0020] In a 500mL flask equipped with a stirrer, dropping funnel, thermometer, and condenser, add calcium hydroxide, hydroxylamine sulfate and reaction solvent in a molar ratio of 1:0.1:9.82. The mass and volume are 55.50g and 12.30 respectively. g, 243.56g, and slowly fill the inert protective gas, stir the reaction raw materials, heat and increase the temperature, after the temperature rises to the reaction temperature, according to the molar ratio of calcium hydroxide to acetone of 1:0.1, the starting mass is 12.43g, and the concentration is 35% acetone-reaction solvent solution, dripping takes 3 hours, after dripping, continue to stir for 5 hours, control the temperature between 40~100℃, after the reaction, let stand for 1~5 hours, filter the reaction system and distill The filtrate obtained the reaction product.

[0021] The analysis results showed that the conversion rate of ketone was 97.58% and the selectivity of oxime was 99.68%.

[0022] Exterior

Embodiment 3

[0024] In a 500mL flask equipped with a stirrer, dropping funnel, thermometer, and condenser, add calcium hydroxide, hydroxylamine sulfate and reaction solvent with a molar ratio of 1:3:25.95. The mass and volume are 13.32g and 88.56, respectively. g, 163.50g, and slowly fill it with inert protective gas, stir the reaction raw materials, heat and increase the temperature, after the temperature rises to the reaction temperature, according to the molar ratio of calcium hydroxide to cyclopentanone 1:3, the starting mass is 105.49g, The 43% cyclopentanone-reaction solvent solution was dripped for 6 hours. After the dripping is completed, continue to stir for 4 hours, control the temperature between 40 and 100°C, after the reaction, let it stand for 1 to 5 hours. The reaction system is filtered, and the filtrate is distilled to obtain a reaction product.

[0025] The analysis results showed that the ketone conversion rate was 99.86%, and the selectivity of oxime was 99.86%.

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com