Method of preparing high strength carbon fibre

A technology of high-strength carbon fiber and high-temperature carbonization, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of complex equipment, tensile strength not reaching the T300 level, and limited application, and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

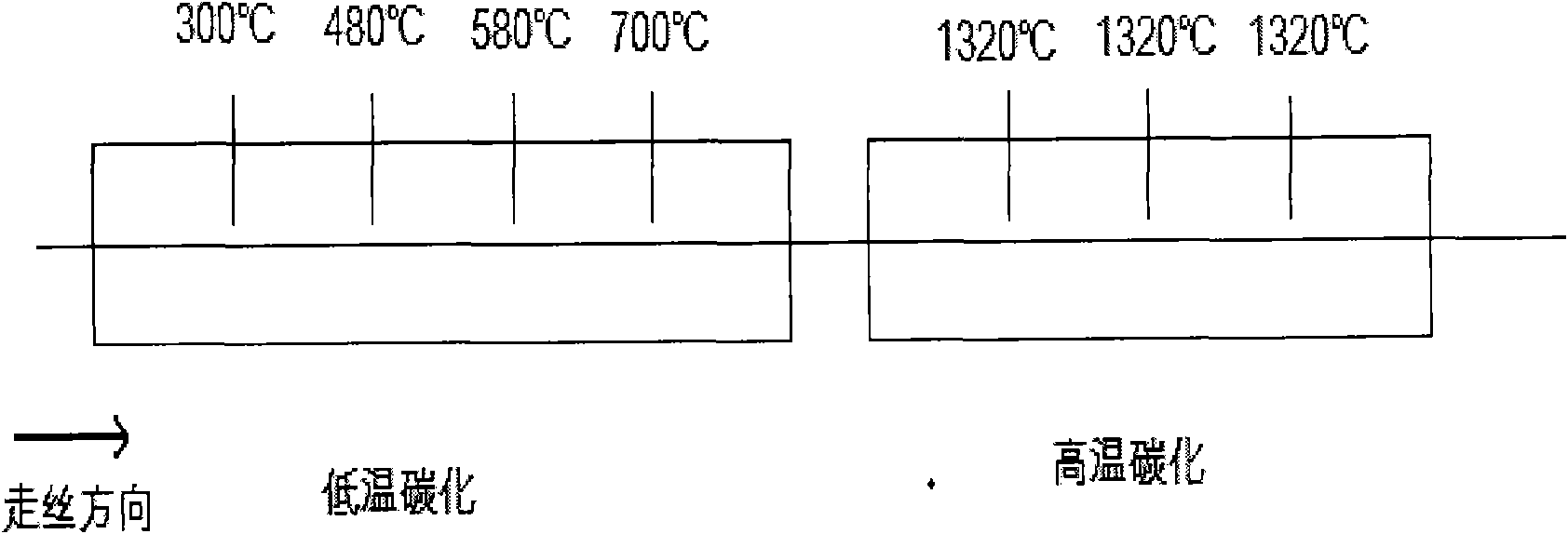

[0015] The polyacrylonitrile copolymer fiber (12K with 12,000 single-filament holes and 1.1 denier (1.22dtex) with a fineness of 1.1 denier (1.22dtex) containing more than 90% of acrylonitrile monomer components is produced by wet spinning. Composition (by mass ratio) is: acrylonitrile 96, methylene succinic acid 1, methyl acrylate 3), carry out modification treatment in the modifying agent of 5wt% hydroxylammonium sulfate, modifying agent temperature 80 ℃, process 5 Minutes, after washing with water, carry out densification physical modification treatment for 5 minutes at 180 ° C in air medium, under the drafting of +10% elongation, and the modified polyacrylonitrile fiber obtained by the above process in the air After 180-300 ℃ pre-oxidation furnace treatment, 10% draft is applied, pre-oxidation time is 60 minutes, and then low and high temperature carbonization treatment (such as figure 1 As shown, using a horizontal carbonization furnace, the temperature of the low-tempera...

Embodiment 2

[0018] The polyacrylonitrile copolymer fiber used, the dipping modification conditions are the same as in Example 1, the densification physical modification temperature is 140 ° C, and the stretching of +15% elongation is applied for 2 minutes, and then the same method as in Example 1 is used. Pre-oxidation and carbonization process to produce carbon fiber.

Embodiment 3

[0020] The polyacrylonitrile copolymer fiber used, the dipping modification conditions are the same as in Example 1, the temperature of the densified physically modified strip is 200 ° C, and the stretching of 0% elongation is applied for 10 minutes, and then the same method as in Example 1 is used. Pre-oxidation and carbonization process to produce carbon fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com