Method for synthesizing dimethyl isophthalate-5-sodium sulfonate

A technology of dimethyl isophthalate and isophthalic acid, which is applied in the field of synthesis of dimethyl isophthalate-5-sodium sulfonate, can solve the problem of demanding equipment anhydrous and affecting product yield and quality , increase in side reactions and other issues, to achieve the effect of reducing the amount of soda ash used, improving production safety, and avoiding the increase in side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

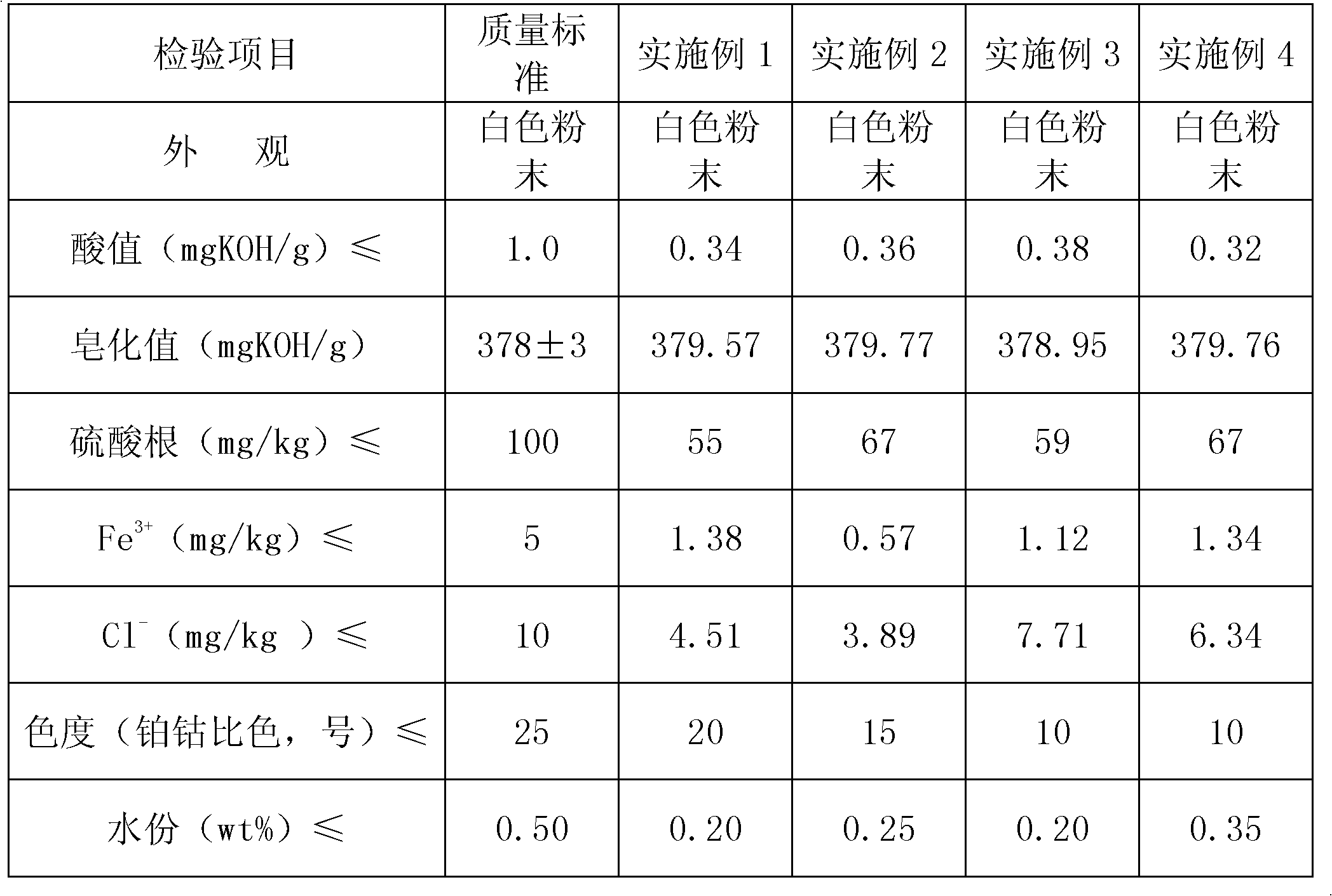

Embodiment 1

[0062] Preparation concentration is the oleum of 64wt%, according to isophthalic acid: oleum: cadmium sulfate: SiO 2 : mercuric sulfate: anhydrous sodium sulfate=1: 0.879: 0.0003: 0.0005: 0.0005: 0.001 The mass ratio of the feed ingredients: first add oleum to the sulfonation kettle at one time, start stirring, add 20% of the total amount of isophthalic acid %, heat the material in the sulfonation tank, raise the temperature of the material to 125°C within 20 minutes, then add all the remaining isophthalic acid to the sulfonation tank, add anhydrous sodium sulfate, and then raise the temperature of the material to 150°C cadmium sulfate was added, and the reaction was kept for 60 minutes; then the temperature of the material was raised to 160°C within 30 minutes, and the reaction was first kept for 20 minutes, and then SiO was added. 2 , and then heat preservation reaction for 60 minutes; finally, within 20 minutes, the temperature of the material was raised to 170°C, and the h...

Embodiment 2

[0067] Preparation concentration is the oleum of 65wt%, according to isophthalic acid: oleum: cadmium sulfate: SiO 2 : mercuric sulfate: anhydrous sodium sulfate=1: 0.885: 0.0006: 0.0009: 0.0009: 0.004 mass ratio ingredients: first add oleum to the sulfonation kettle at one time, start stirring, add 24% of the total amount of isophthalic acid %, heat the material in the sulfonation tank, raise the temperature of the material to 128°C within 24 minutes, then add all the remaining isophthalic acid to the sulfonation tank, add a small amount of anhydrous sodium sulfate, and then raise the temperature of the material to At 153°C, add cadmium sulfate and keep it warm for 70 minutes; then within 35 minutes, the temperature of the material rises to 163°C, first keep it warm for 24 minutes, then add SiO 2 , and then heat preservation reaction for 68 minutes; finally, within 30 minutes, the temperature of the material was raised to 173° C., and the heat preservation reaction was carried ...

Embodiment 3

[0072] Preparation concentration is the oleum of 66wt%, according to isophthalic acid: oleum: cadmium sulfate: SiO 2 : mercury sulfate: anhydrous sodium sulfate = 1: 0.889: 0.0008: 0.0010: 0.0012: 0.008 mass ratio of feed ingredients: first add oleum to the sulfonation kettle at one time, start stirring, add 26% of the total amount of isophthalic acid , heat the material in the sulfonation tank, raise the temperature of the material to 130°C within 28 minutes, then add all the remaining isophthalic acid into the sulfonation tank, and then increase the temperature of the material to 156°C, add cadmium sulfate, and keep warm React for 70 minutes; then within 40 minutes, the temperature of the material rises to 166°C, and the temperature is kept for 28 minutes before adding SiO 2 , and then heat preservation reaction for 75 minutes; finally, within 40 minutes, the temperature of the material was raised to 176°C, and the heat preservation reaction was carried out for 36 minutes, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com