Zirconium silicate covered cadmium selenide sulfide pigment for ceramic inkjet printing or ceramic dry blending and preparation method thereof

A cadmium sulfur selenide and ceramic inkjet technology, applied in the field of ceramic pigments, can solve the problems of large specific gravity, increased environmental protection costs and production safety costs, and is not suitable for large-scale production, and achieves the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

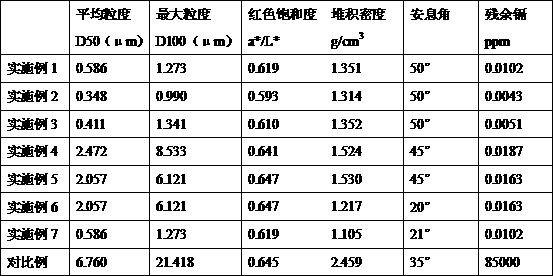

Examples

Embodiment 1

[0024] Slowly drop 0.4mol / L water glass solution into 2mol / L sulfuric acid solution to form a weakly acidic silicic acid solution with pH=3.

[0025]Slowly drop 0.4mol / L sodium carbonate solution into the strongly acidic mixed solution of zirconium oxychloride (2mol / L), cadmium sulfate, thiourea, and ammonium fluoride to form a weakly acidic mixed solution with pH=3, in which oxygen The mass ratio of zirconium chloride, cadmium sulfate, thiourea and ammonium fluoride is 1:0.2:0.4:0.05.

[0026] Massive Zr 4+ : Si 4+ =1:1.1 Mix the above two weakly acidic solutions with equal pH, add ultra-fine selenium powder, and add lignosulfonate dispersant, stir for 15 minutes and let it stand for 16 hours to naturally form a translucent jelly-like gel, in which selenium powder is added The amount is 10% of the mass of cadmium sulfate, and the average particle size of selenium powder is 0.8 μm.

[0027] The gel was dried at 40°C for 36h and then sealed and calcined at 700°C for 2h to ob...

Embodiment 2

[0029] On the basis of Example 1, add Mg to the strongly acidic mixed solution of zirconium oxychloride, cadmium sulfate, thiourea, ammonium fluoride 2+ Metal ions, Mg 2+ Introduced by magnesium chloride, Mg 2+ The amount added is 0.005% of the mass of zirconium oxychloride.

Embodiment 3

[0031] On the basis of Example 1, Y is added to the strongly acidic mixed solution of zirconium oxychloride, cadmium sulfate, thiourea, and ammonium fluoride 3+ metal ion, Y 3+ Introduced by yttrium chloride, Y 3+ The amount added is 0.005% of the mass of zirconium oxychloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com