Arc-welding molten drop necking formation detection method and control method after necking formation

An arc welding and control method technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of misjudged welding energy distribution, no way to directly detect and control, poor and other problems, achieve compensation delay, avoid The effect of violent occurrence of electric explosion and avoiding misjudgment of necking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

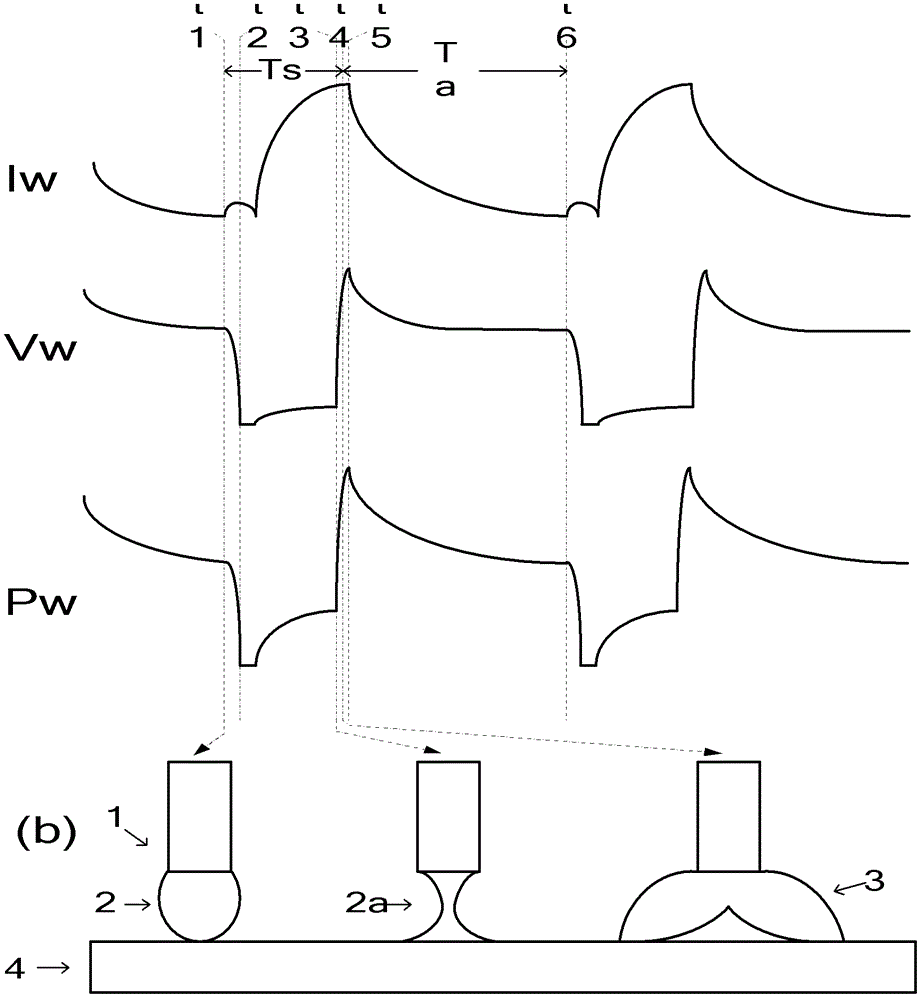

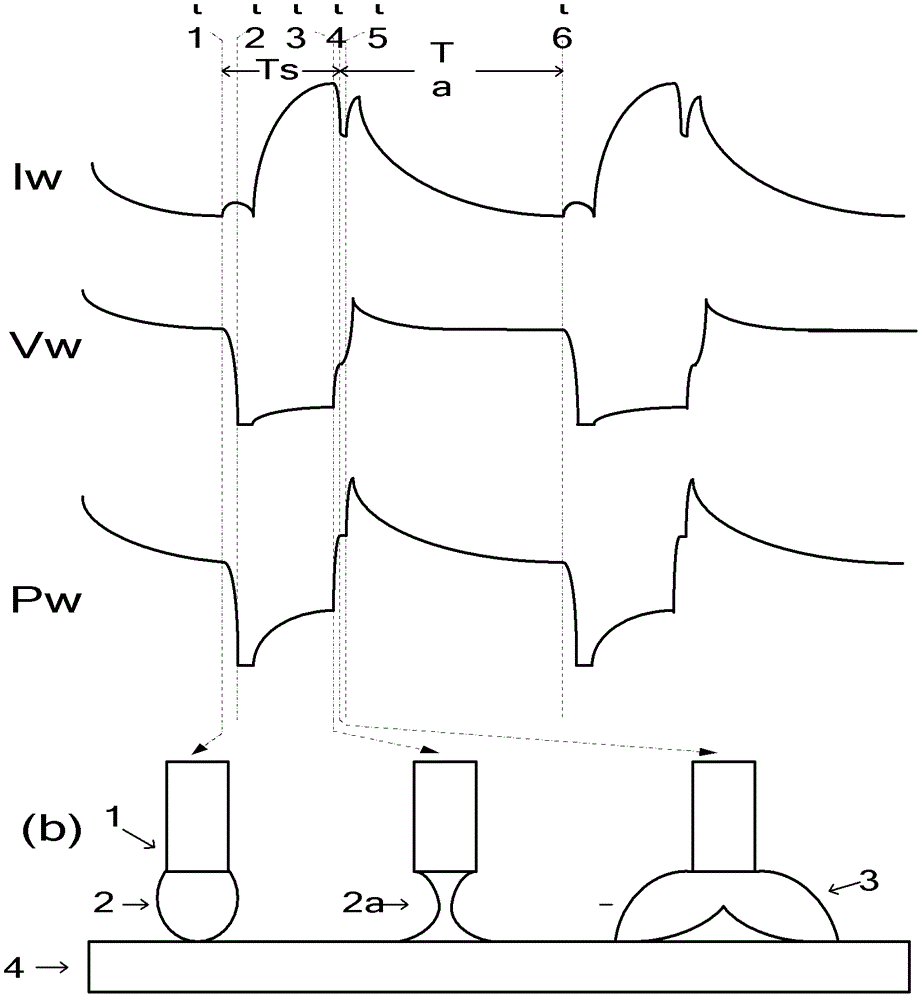

[0025] Figure 4 It is a block diagram of the present invention concerning detection and control of droplet necking in arc welding. The main circuit is controlled by DSP, which includes detection circuit, power calculation unit, current adjustment unit, voltage adjustment unit VR, power regulator PR, state switching circuit SW, current loop initial value setting unit Ia_init and multiplexer Mux.

[0026] The wire feeder of the welding machine feeds wire at a constant speed, detects the welding voltage Vw between the end of the welding wire and the workpiece through the voltage detection unit Vd, detects the welding current Iw flowing through the welding wire and the workpiece through the current detection unit Id, and samples the voltage and current The signal passes through the filter circuit to filter out the interference signals from the inside and outside of the welding system to obtain the welding voltage sampling signal Vs and welding current sampling signal Is. The ampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com