Cadmium sulfoselenide occlusion pigment, ceramic ink and preparation method of cadmium sulfoselenide occlusion pigment

A technology for wrapping colorants and cadmium sulfide selenide, applied in inks, fibrous fillers, printing, etc., can solve the problems of volatilization or oxidation of inorganic colorants, affecting color and lustre, and limited application, so as to avoid clogging the network. The effect of plate hole and ink jet hole, high chroma, fine color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

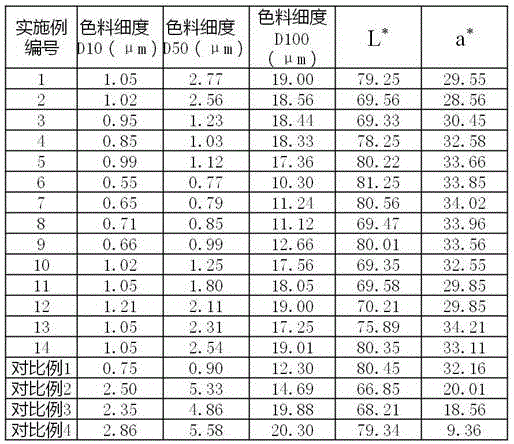

Examples

preparation example Construction

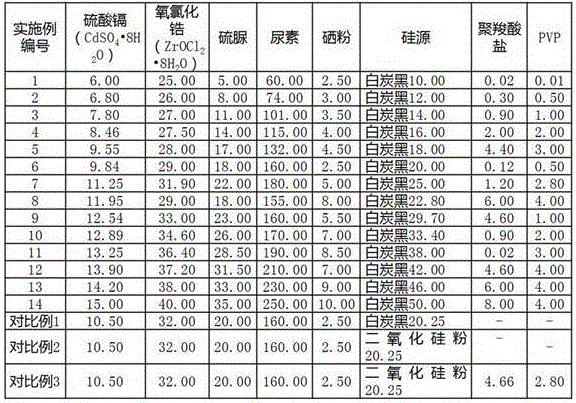

[0028] Concrete preparation method is as follows steps:

[0029] Step ① Weigh cadmium sulfate (CdSO 4 •8H 2 O) and zirconium oxychloride (ZrOCl 2 •8H 2 O), add water to dissolve; the added quality of water is 3-5 times of the weight of the solid.

[0030] ② Weigh urea, thiourea and selenium powder according to the formula table, and add water to dissolve; the added quality of water is 5-10 times of the weight of solid matter.

[0031] ③ Weigh the dispersant polycarboxylate and PVP according to the formula table, and dissolve them in 2000-2500ml of water.

[0032] ④Mix the solutions in steps ①-③, add the silicon source, and mix evenly; in this step, ultrasound can be used to assist dispersion.

[0033] ⑤Pour the mixed reaction solution in step ④ into the reaction kettle, adjust the temperature to 60-200°C, the rotation speed to 100-300r / min, and react for 5-24h.

[0034] ⑥ Take out the reaction precursor obtained in step ⑤, wash with water, filter with suction, and dry.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com