Method of recovering cadmium from cadmium-containing high-arsenic soot

A technology of soot and arsenic, which is applied in chemical instruments and methods, improvement of process efficiency, iron compounds, etc., to avoid the effect of highly toxic arsenic hydrogen gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

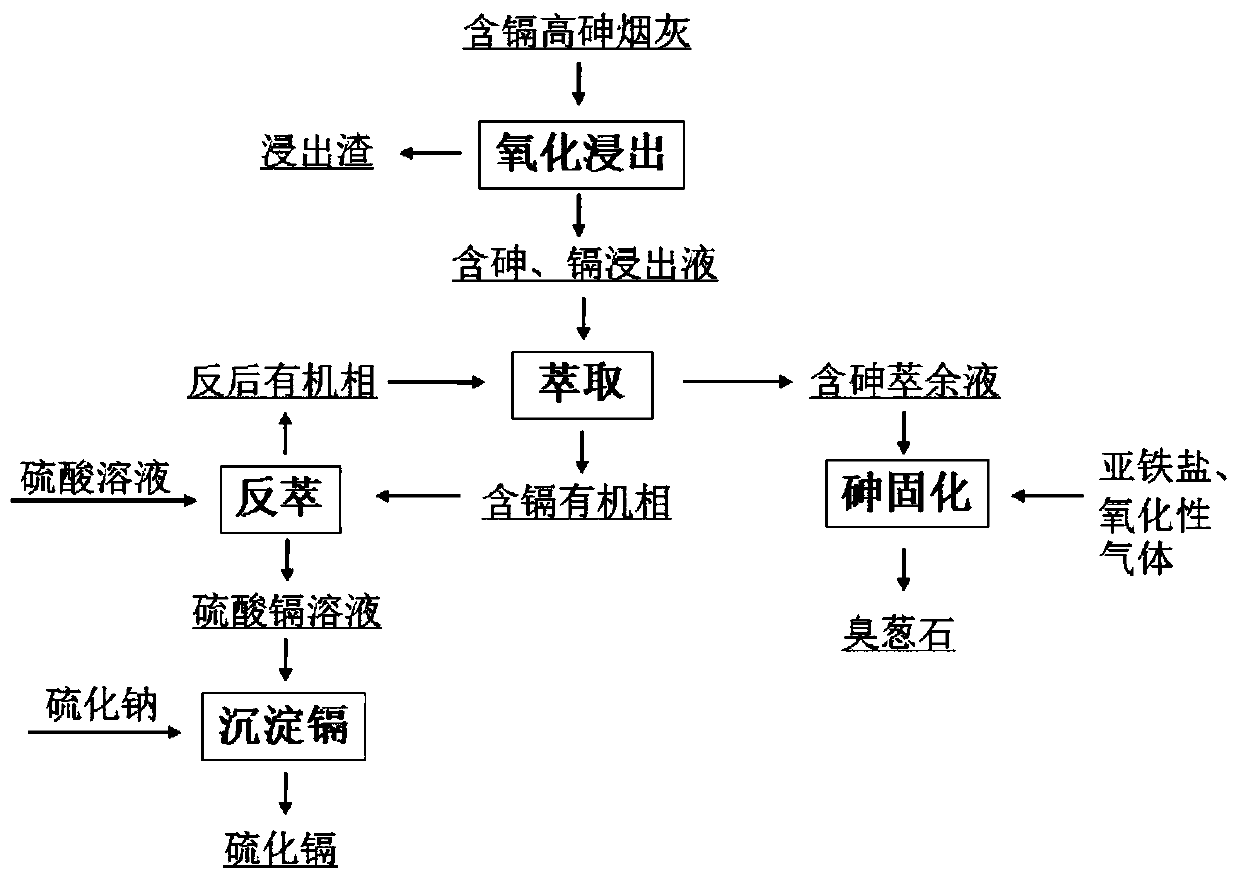

Method used

Image

Examples

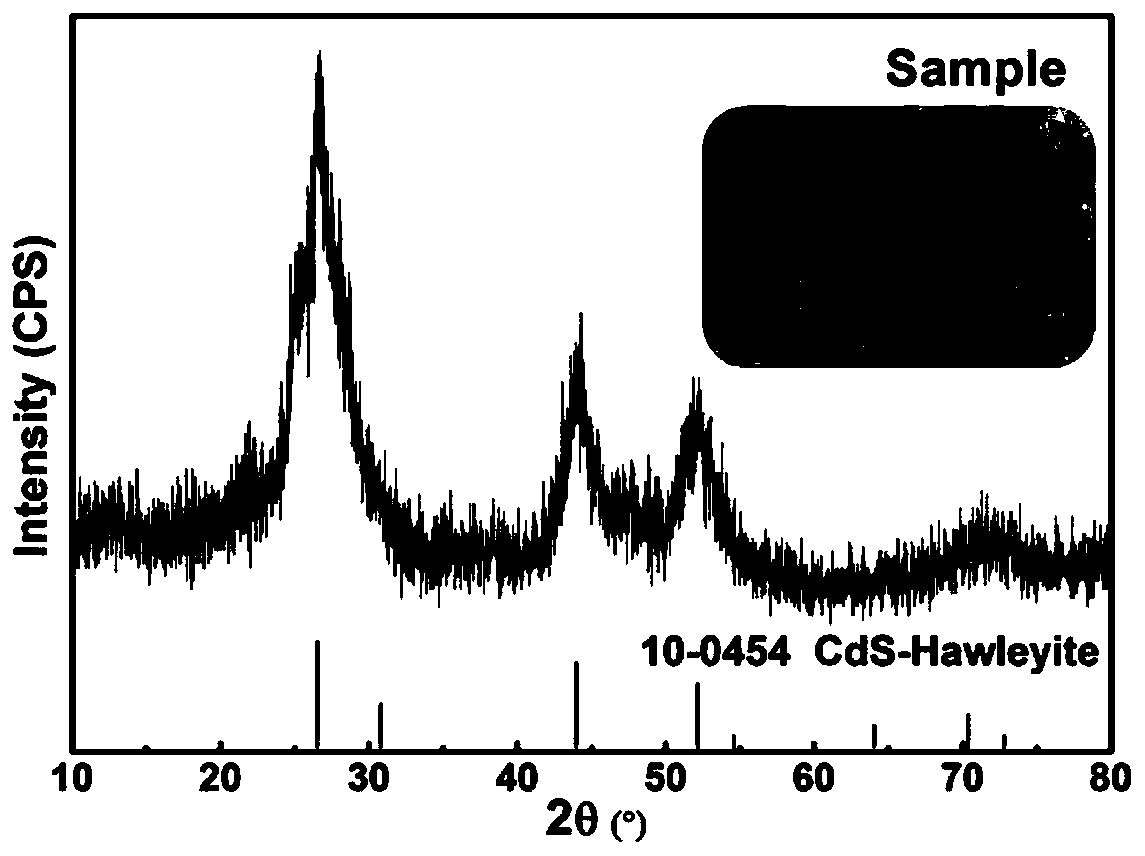

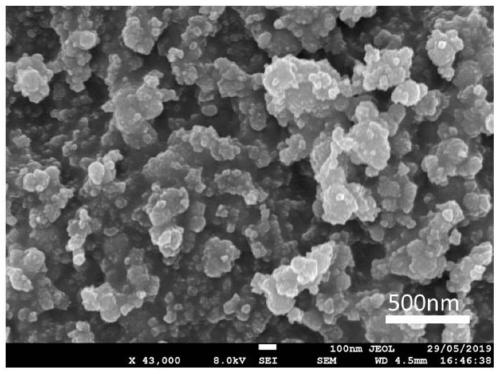

Embodiment 1

[0035] Get 60ml mass fraction 30% hydrogen peroxide (H 2 o 2 The molar concentration is 9.8mol / L) and 340ml of water are added to make a leachate, add 80g of the above-mentioned raw materials, stir for 4 hours and filter to obtain a leachate containing cadmium and arsenic elements and a leach residue containing valuable metals, and the obtained leach residue is sent to recover lead, of which cadmium The leaching rate of arsenic is 88.2%, and the leaching rate of arsenic is 97.3%. Use sodium hydroxide solution to adjust the pH of the leaching solution containing cadmium and arsenic to 2.7, and then use P204 (P204: 2-octanol: sulfonated kerosene = 6:1:13, water phase: oil phase = 1:1) Four stages of countercurrent extraction of cadmium, after each stage of extraction, use sodium hydroxide solution to adjust the pH to 2.7 before proceeding to the next stage of extraction, the extraction time is 15min, and the extraction rate of cadmium is 98.6%. Gained cadmium-containing organi...

Embodiment 2

[0037] Get 72ml mass fraction 30% hydrogen peroxide (H 2 o 2 The molar concentration is 9.8mol / L) and 408ml of water are added to make a leachate, add 80g of the above-mentioned raw materials, stir for 4 hours and filter to obtain a leachate containing cadmium and arsenic elements and a leach residue containing valuable metals, and the obtained leach residue is sent to recover lead, of which cadmium The leaching rate of arsenic is 90.9%, and the leaching rate of arsenic is 94.8%. Use sodium hydroxide solution to adjust the pH of the leaching solution containing cadmium and arsenic to 2.7, and then use P204 (P204: 2-octanol: sulfonated kerosene = 15:1:34, water phase: oil phase = 1:1) Four stages of countercurrent extraction of cadmium, after each stage of extraction, use sodium hydroxide solution to adjust the pH to 2.7 before proceeding to the next stage of extraction. The back extraction time is 15 minutes, and the extraction rate of cadmium is 98.7%. The obtained cadmium-co...

Embodiment 3

[0039] Get 80ml mass fraction 30% hydrogen peroxide (H 2 o 2 The molar concentration is 9.8mol / L) and 320ml of water are added to make a leachate, add 80g of the above-mentioned raw materials, stir for 3 hours and filter to obtain a leachate containing cadmium and arsenic elements and a leach residue containing valuable metals, and the obtained leach residue is sent to recover lead, of which cadmium The leaching rate of arsenic is 86.2%, and the leaching rate of arsenic is 99.2%. Use sodium hydroxide solution to adjust the pH of the leaching solution containing cadmium and arsenic to 2.7, and then use P204 (P204: 2-octanol: sulfonated kerosene = 6:1:13, water phase: oil phase = 1:1) Four stages of countercurrent extraction of cadmium, after each stage of extraction, use sodium hydroxide solution to adjust the pH to 2.7 before proceeding to the next stage of extraction, the extraction time is 15 minutes, and the extraction rate of cadmium is 98.8%. Gained cadmium-containing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com