Deformation reinforcing method of karst cave tunnel initial support

A technology for tunnels and karst caves, which is used in tunnels, tunnel linings, and earth-moving drilling and mining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

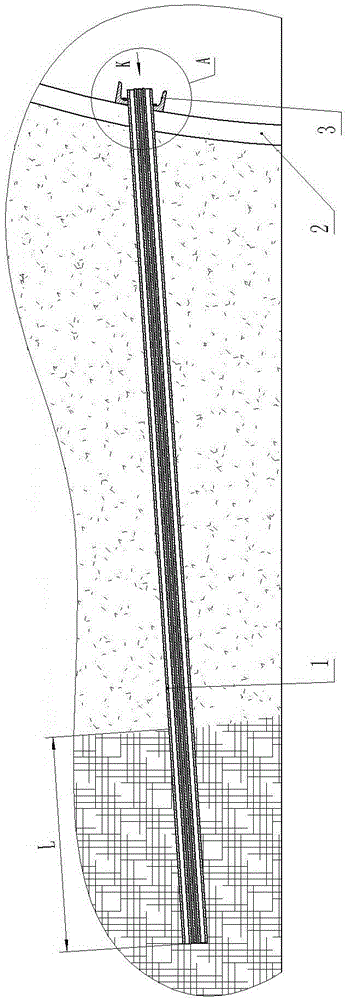

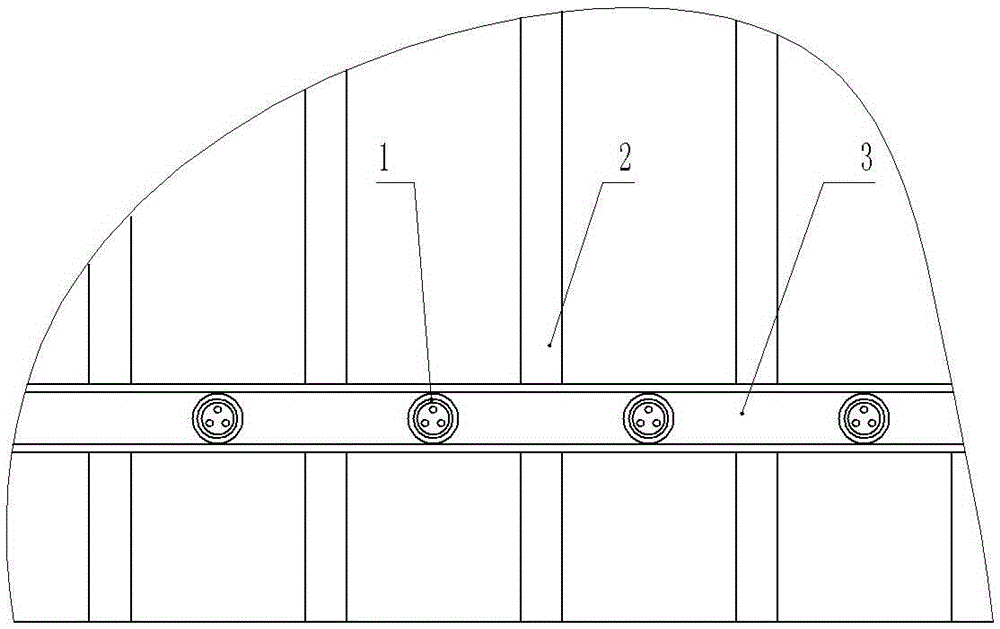

[0026] Such as figure 1 and image 3 The primary support of the tunnel shown includes a plurality of arched steel beams 2 arranged at intervals on the tunnel. The arched steel beams 2 of this embodiment are made of I-shaped steel. The above-mentioned method for strengthening the deformation of the primary support of the karst cave tunnel includes the following steps :

[0027] A. A plurality of anchor pipes 1 protruding into the weak surrounding rock are arranged at intervals on the side walls of the tunnel on both sides of the primary branch deformation section of the karst cave tunnel. Anchor pipe 1 spacing is 1.8 meters;

[0028] The installation method of anchor pipe 1 is as follows:

[0029] a, drill a plurality of inclined downward anchor pipe installation holes in the side wall of the tunnel, the diameter of the anchor pipe installation hole of the present embodiment is 108 millimeters; The inclination angle a between the center line and the horizontal direction is ...

Embodiment 2

[0036] Such as figure 1 and image 3 The primary support of the tunnel shown includes a plurality of arched steel beams 2 arranged at intervals on the tunnel. The arched steel beams 2 of this embodiment are made of I-shaped steel. The above-mentioned method for strengthening the deformation of the primary support of the karst cave tunnel includes the following steps :

[0037] A. A plurality of anchor pipes 1 protruding into the weak surrounding rock are arranged at intervals on the side walls of the tunnel on both sides of the primary branch deformation section of the karst cave tunnel. Anchor pipe 1 spacing is 2.2 meters;

[0038] The installation method of anchor pipe 1 is as follows:

[0039] a, drill a plurality of inclined downward anchor pipe installation holes in the side wall of the tunnel, the diameter of the anchor pipe installation hole of the present embodiment is 108 millimeters; The inclination angle a between the center line and the horizontal direction is ...

Embodiment 3

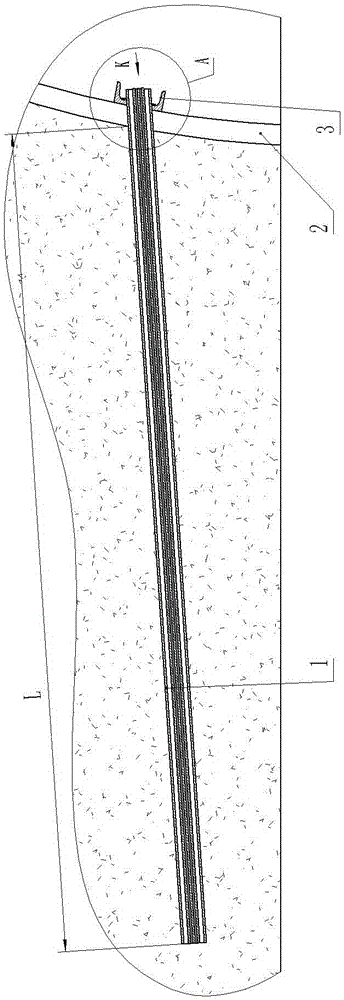

[0046] Such as figure 2 and image 3 The primary support of the tunnel shown includes a plurality of arched steel beams 2 arranged at intervals on the tunnel. The arched steel beams 2 of this embodiment are made of I-shaped steel. The above-mentioned method for strengthening the deformation of the primary support of the karst cave tunnel includes the following steps :

[0047] A. A plurality of anchor pipes 1 protruding into the weak surrounding rock are arranged at intervals on the side walls of the tunnel on both sides of the primary branch deformation section of the karst cave tunnel. Anchor pipe 1 spacing is 2 meters;

[0048] The installation method of anchor pipe 1 is as follows:

[0049]a, drill a plurality of inclined downward anchor pipe installation holes in the side wall of the tunnel, the diameter of the anchor pipe installation hole of the present embodiment is 108 millimeters; The inclination angle a between the center line and the horizontal direction is 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com