Split adjustable reinforcing component device and construction method thereof

A technology for reinforcing components and adjusting components, which is applied in covering/lining, construction, building construction, etc., can solve the problems of high hidden danger of safety accidents, poor stability of steel skeleton, and affecting the effect of beautiful space design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

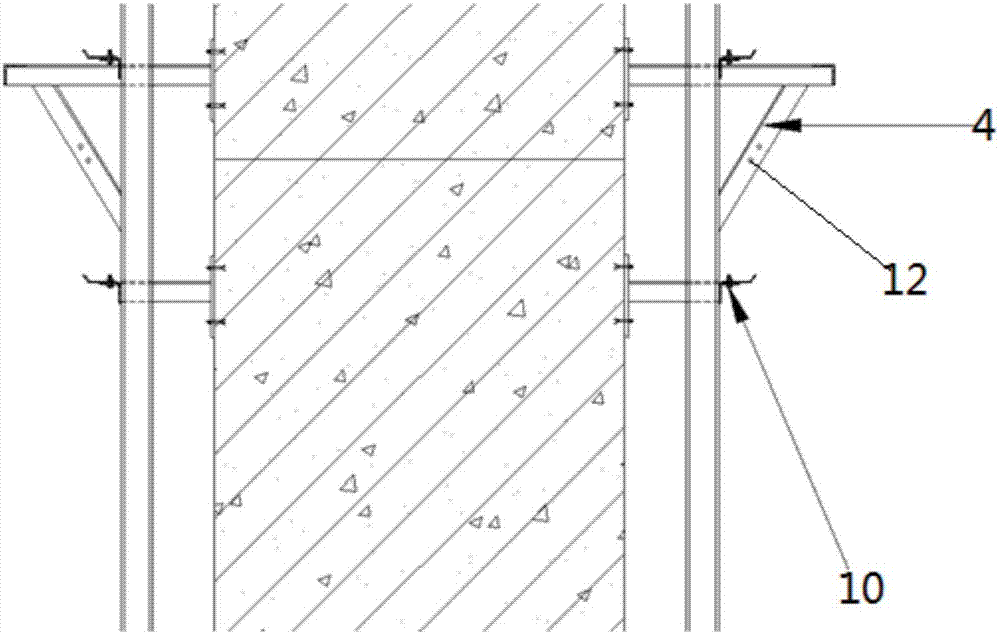

[0038] In order to achieve the purpose of the present invention, as Figure 1-6 As shown, the split-type adjustable reinforcement assembly includes:

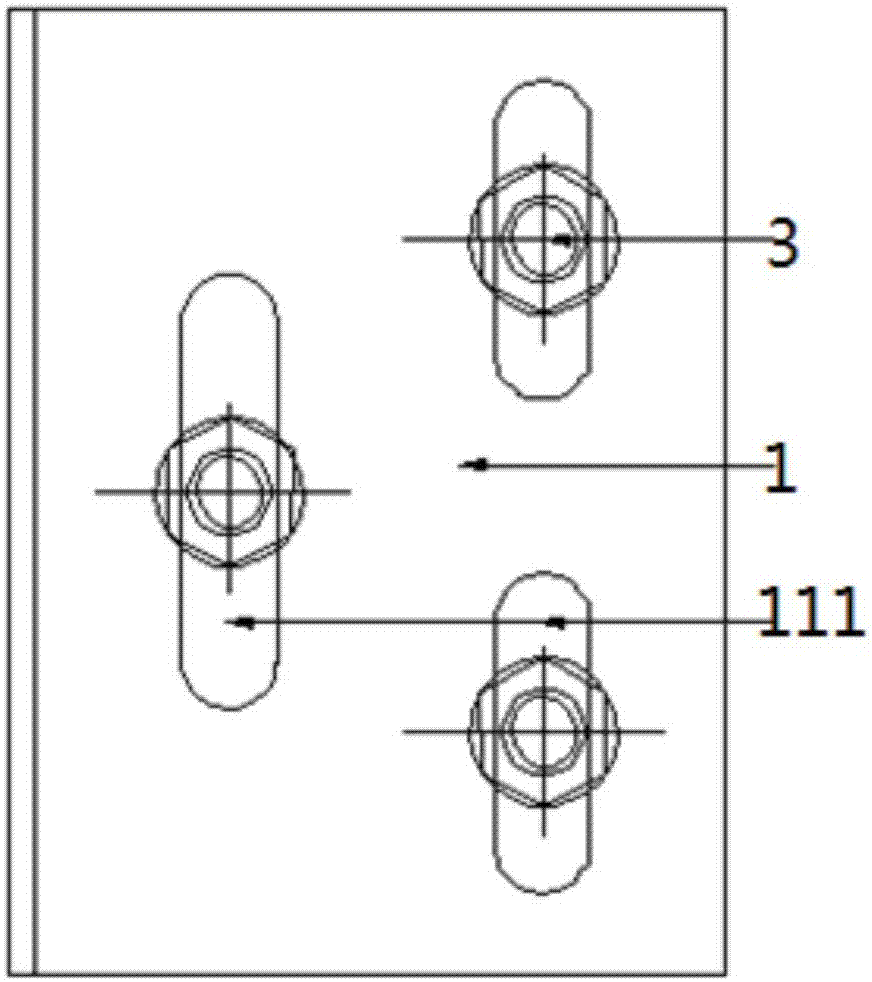

[0039] Steel frame base split adjustment assembly 1: the steel frame base split adjustment assembly 1 is provided with a first reinforcement assembly adjustment hole 111, which is fixedly connected with the circular galvanized angle steel reinforcement 4;

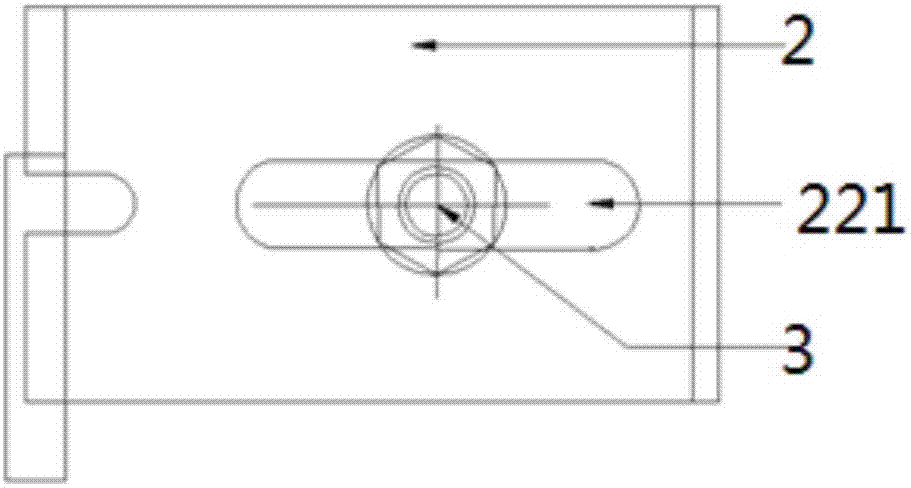

[0040] Split-type adjustment and reinforcement component 2 for the stone surface layer: the split-type adjustment and reinforcement component 2 for the stone surface layer is provided with an adjustment hole 221 for the second reinforcement component, which is fixedly connected with the bell-shaped stone 5;

[0041] The bolts 3 are all passed through the adjustment hole 111 of the first reinforcement assembly and the adjustment hole 221 of the second reinforcement assembly, and the split adjustment assembly 1 of the steel frame base is adjusted by the split adjustment of the ...

Embodiment 2

[0064] The rest are the same as the above-mentioned embodiment, the difference is that the galvanized channel steel 8 is pre-embedded on the galvanized steel plate 7 on the ground according to the drawing design requirements, and then the galvanized steel plate 7 is pre-embedded on the original structure column 6, and the The zinc angle steel connecting piece 9 is fixedly connected with the galvanized channel steel 8 through the bolt 3, which ensures the positioning and installation of the load-bearing mechanical requirements of the device.

[0065] The base layer split adjustment and reinforcement component 1 of the steel frame is adjusted and positioned and installed on the pre-punched circular galvanized angle steel reinforcement 4; and the stone surface layer split adjustment and reinforcement component 2 is pre-embedded in the horn On the mouth-shaped stone 5; the stone surface layer split-type adjustment and reinforcement assembly 2 and the steel frame base-layer split-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com