Circular wood block cutting and forming equipment for machining

A technology for molding equipment and wood blocks, applied in sawing equipment, wood processing equipment, circular saws, etc., can solve problems such as inability to fix, sawdust pollution, wood waste, etc., and achieve the effect of saving manpower and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

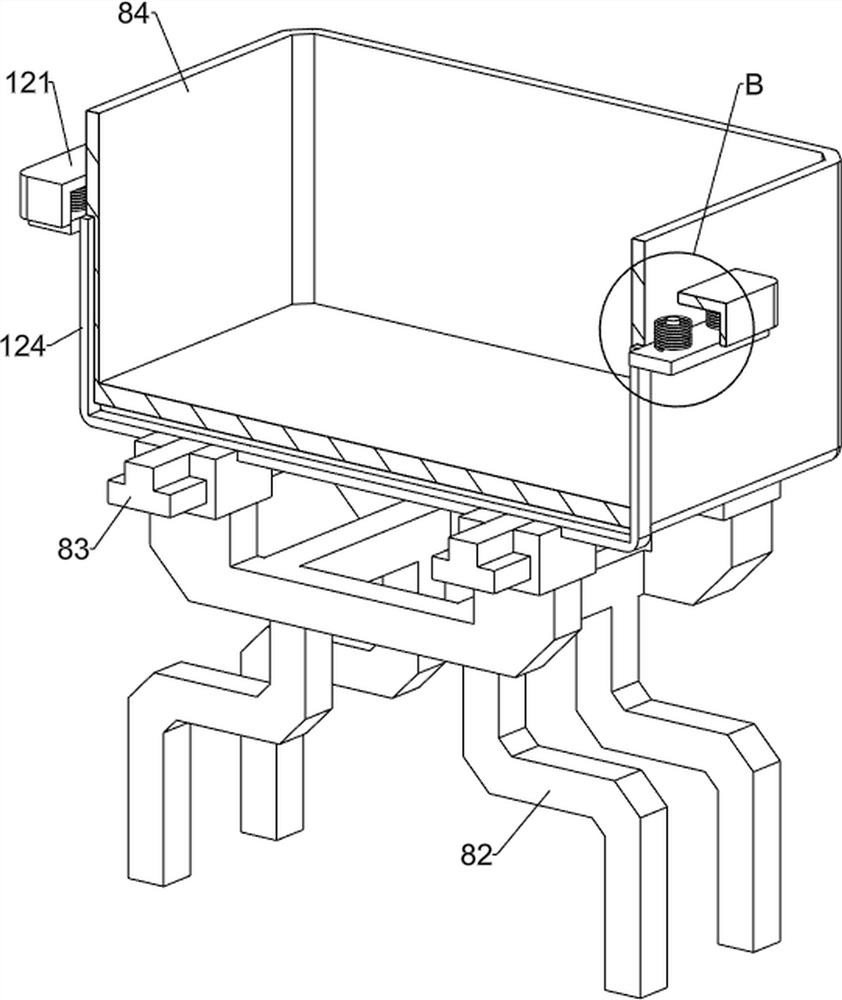

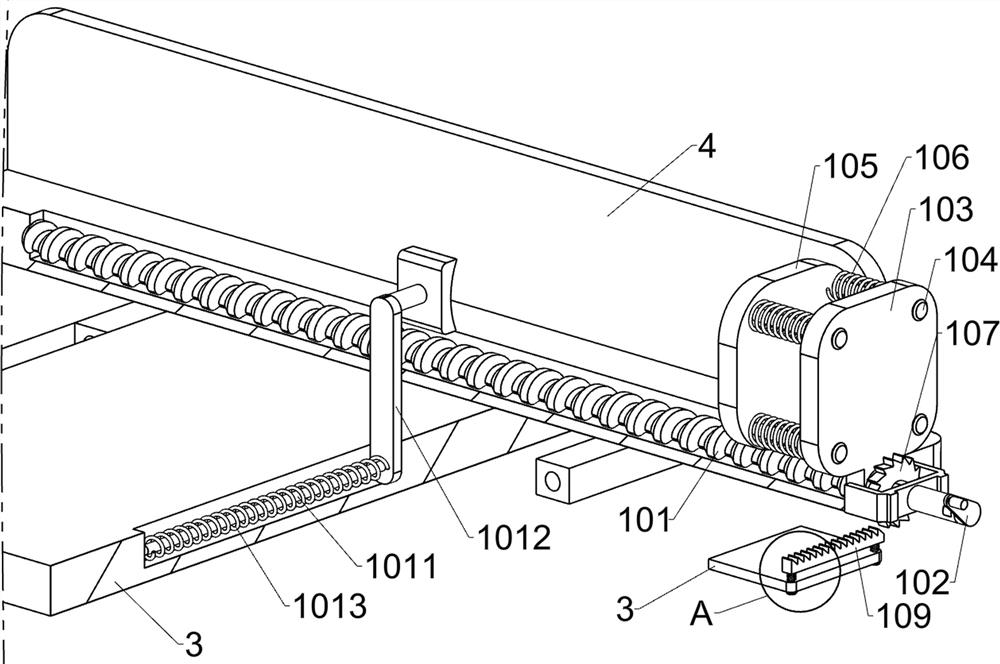

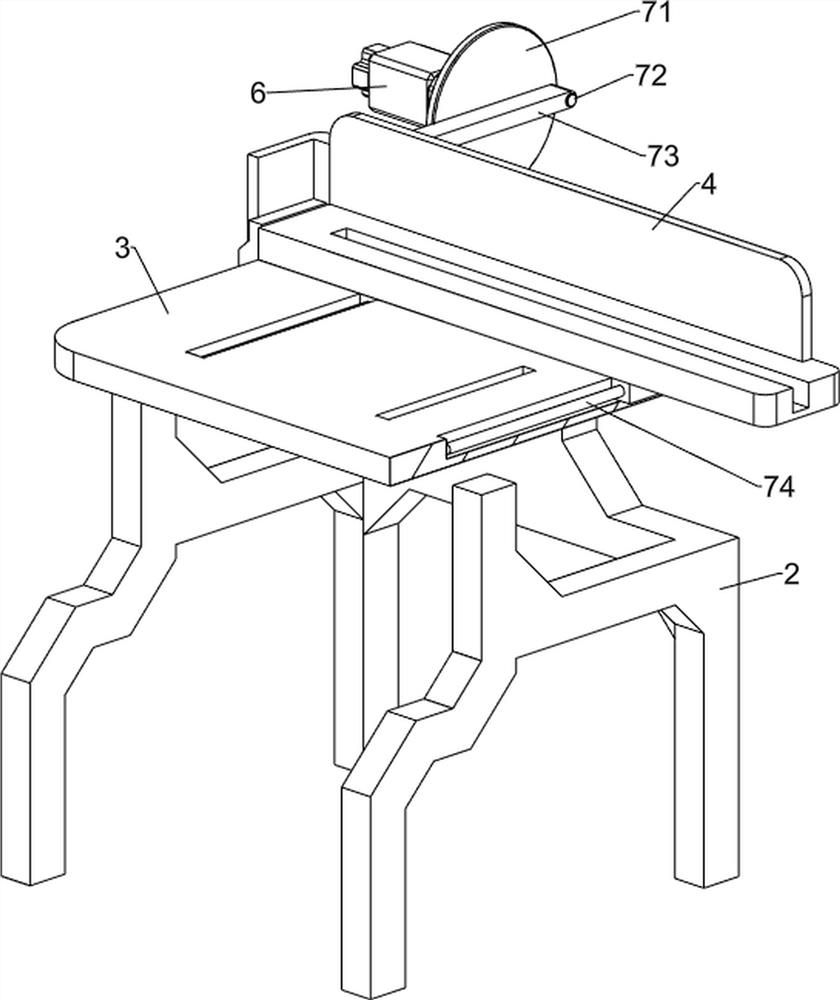

[0029] A kind of round wood block cutting and forming equipment for processing, such as Figure 1-Figure 3 As shown, it includes a base 1, a first support frame 2, a workbench 3, a placement plate 4, a saw blade 5, a motor 6, a reciprocating assembly 7 and a collection assembly 8, and the top of the base 1 is provided with a first support frame 2, the first A workbench 3 is provided on the top of a support frame 2, a sliding plate 4 is provided on the right side of the workbench 3, a saw blade 5 is provided on the left rear side of the workbench 3, and a motor 6 is provided on the right rear side of the top of the base 1. A reciprocating assembly 7 is connected between the motor 6 and the placing plate 4 , and a collection assembly 8 is provided on the rear side of the top of the base 1 .

[0030] First place the round wood on the placement board 4, the starting motor 6 cooperates with the reciprocating motion assembly 7 to drive the placement board 4 to move to the left, and ...

Embodiment 2

[0036] On the basis of Example 1, such as Figure 4-Figure 9 As shown, the fixed assembly 9 is also included, and the fixed assembly 9 includes a first support rod 91, a second guide rod 92, a second support rod 93, a roller 94 and a first spring 95, and the left side of the placement plate 4 is arranged symmetrically front and back. The first support rod 91, the first support rod 91 is equipped with a second guide rod 92 symmetrically sliding up and down, the second guide rod 92 is equipped with a second support rod 93, and the second support rod 93 is of a rotating type. Rollers 94 are provided, and first springs 95 are symmetrically connected between the first support rod 91 and the second support rod 93 , and the first springs 95 are respectively sleeved on the second guide rods 92 .

[0037] When people need to install the round timber on the placement board 4, first the second support rod 93 is pulled to the left, the first spring 95 is compressed, and after the round ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com