Composite components curing process and composite parts

A composite material component and curing process technology, applied in the field of materials, can solve the problems of high manufacturing cost, high requirements for curing pressure uniformity, and dangerous use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention provides a composite material component curing process, which comprises the following steps:

[0026] 1) Heat and heat-preserve the composite material parts to be processed in the vibration experiment platform, wherein the heating and heat preservation treatment is to heat the composite material parts to be processed in the vibration experiment platform at a heating rate of 1.5°C / min from 30 ℃ heating to 80 ℃, heat preservation 30min; heating and heat preservation using nickel-chromium alloy heating wire heater for heating or heat preservation; the vibration frequency range of the vibration experiment platform is 10HZ-2000HZ; the temperature range of the vibration experiment platform is -70℃-200℃; vibration The vibration acceleration of the experimental platform is not greater than 50g, g=9.8m / s.

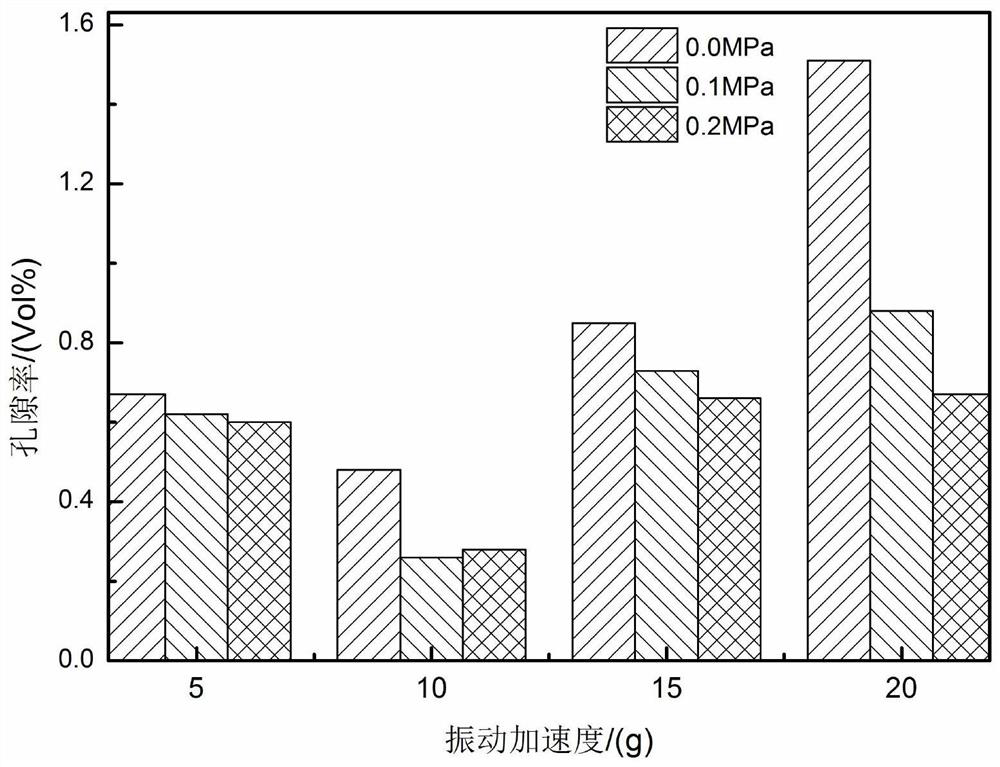

[0027] 2) In the process of heating and heat preservation, provide vibration to the composite material parts to be processed through the vibration experiment pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

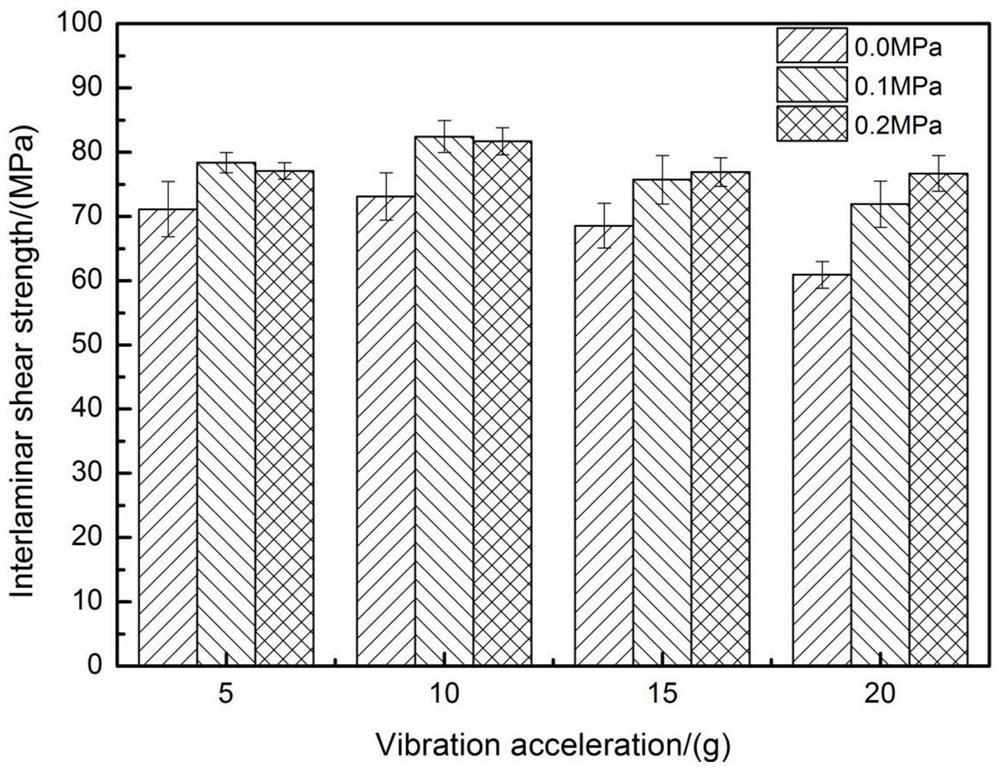

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

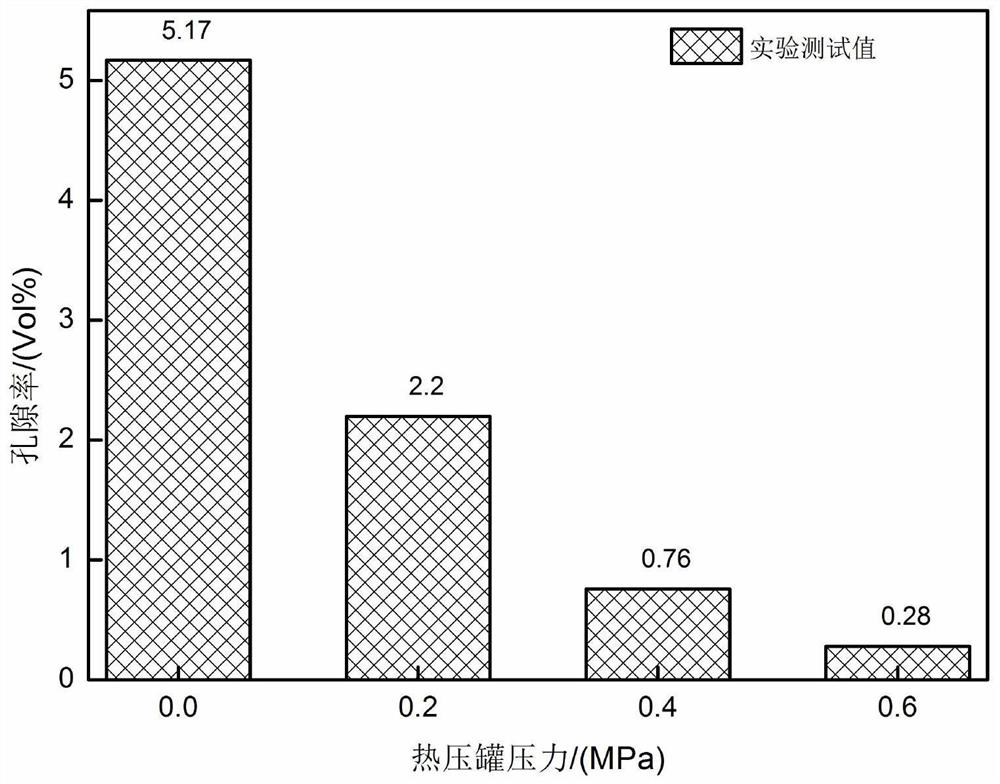

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com