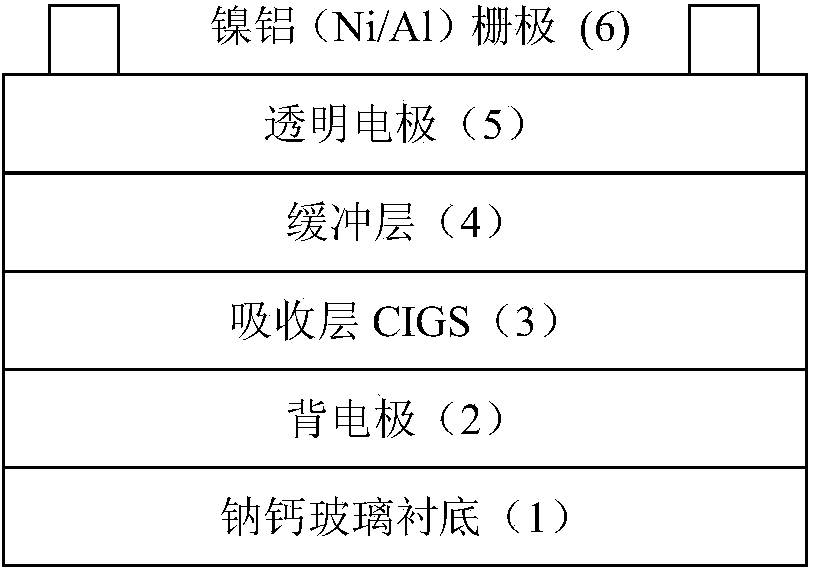

Surface passivation technology capable of improving performance of copper indium gallium selenium thin-film solar cells

A solar cell, copper indium gallium selenide technology, applied in the field of solar cells, can solve the problems of human environmental pollution, air pollution, waste of natural resources and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention more clear, the following will be described in detail in combination with specific examples and with reference to the accompanying drawings.

[0021] 1. Wash the soda-lime glass substrate repeatedly in the cleaning agent, then soak it in deionized water, acetone and isopropanol solution and ultrasonic for 10-30 minutes each, and finally dry it in the oven

[0022] 2. Put the cleaned glass substrate into a vacuum chamber to sputter the substrate metal Mo layer as the back electrode. The working air pressure during sputtering is 5mtorr, and the sputtering power is 500W.

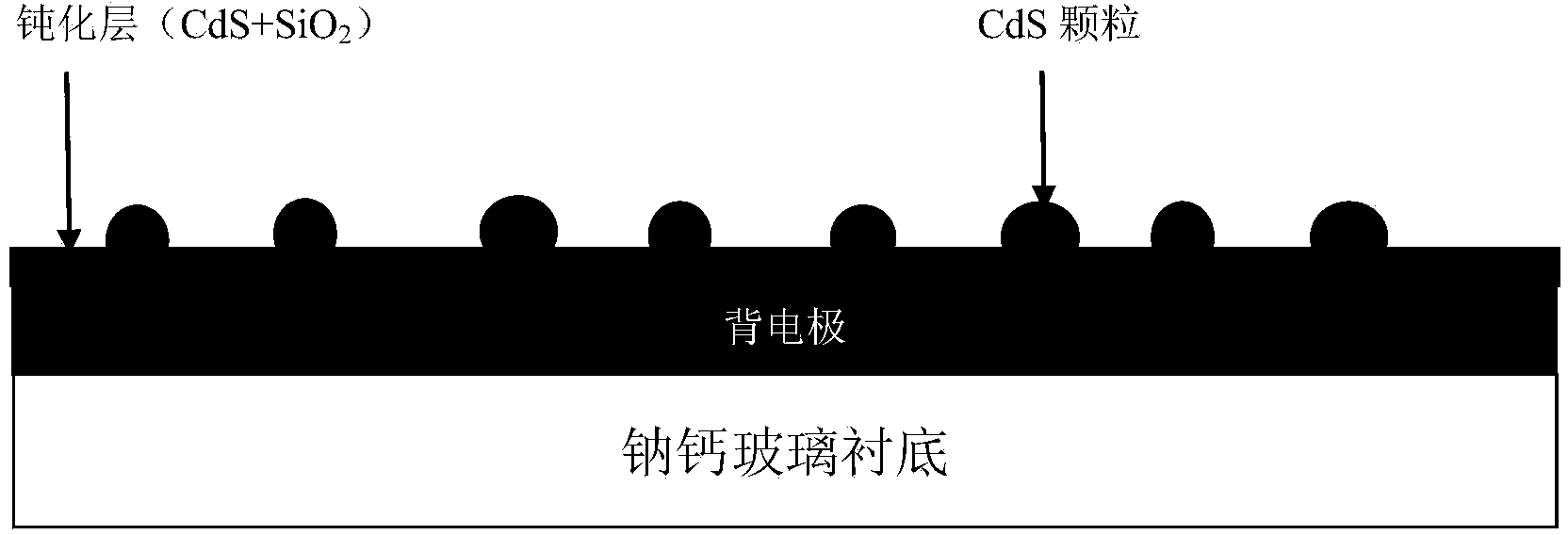

[0023] 3. A water bath method is used to grow a CdS layer on a glass substrate deposited with a Mo layer. The method is as follows: Put the container mixed with 1-2.5M ammonia water, 0.001-0.01M cadmium sulfate, and 0.05-0.5M thiourea solution into a water bath and heat for 2-10 minutes. At this time, cadmium sulfid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com