Composite titanium dioxide nanoflower photoelectrocatalysis material and preparation and application thereof

A titanium dioxide, photoelectric catalysis technology, applied in physical/chemical process catalysts, nanotechnology, nanotechnology and other directions, can solve the problems of complicated preparation methods and harsh reaction conditions, and achieve the effects of low cost, low equipment requirements, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

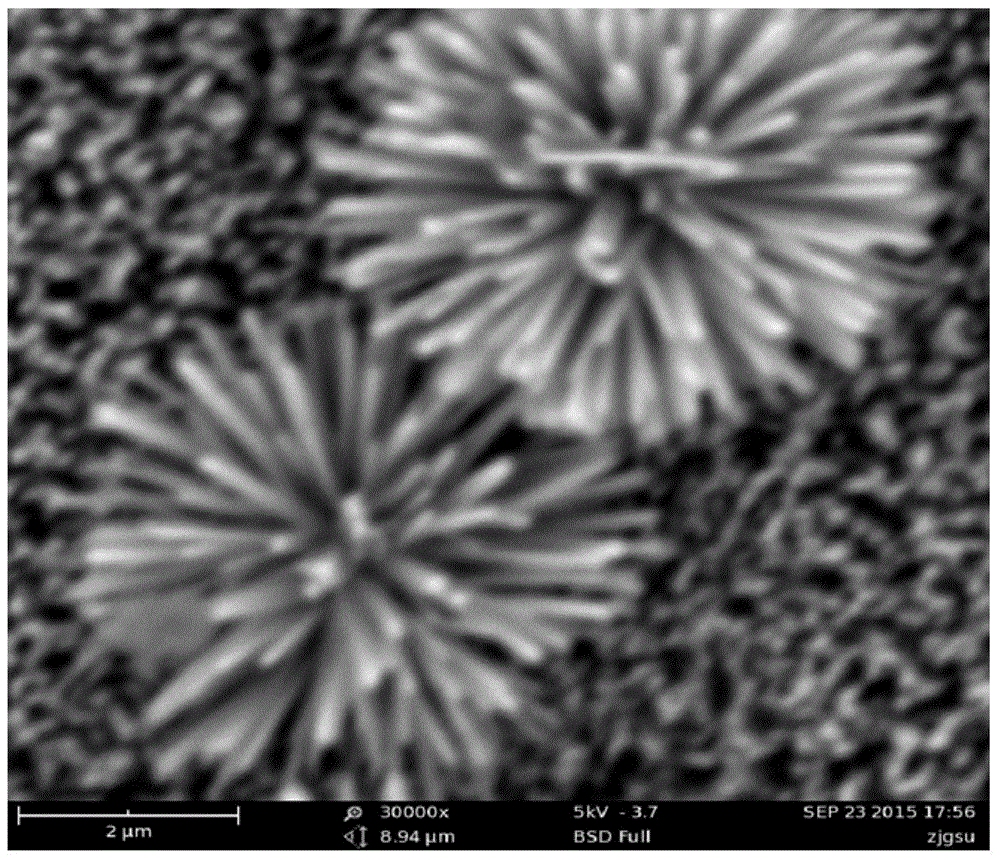

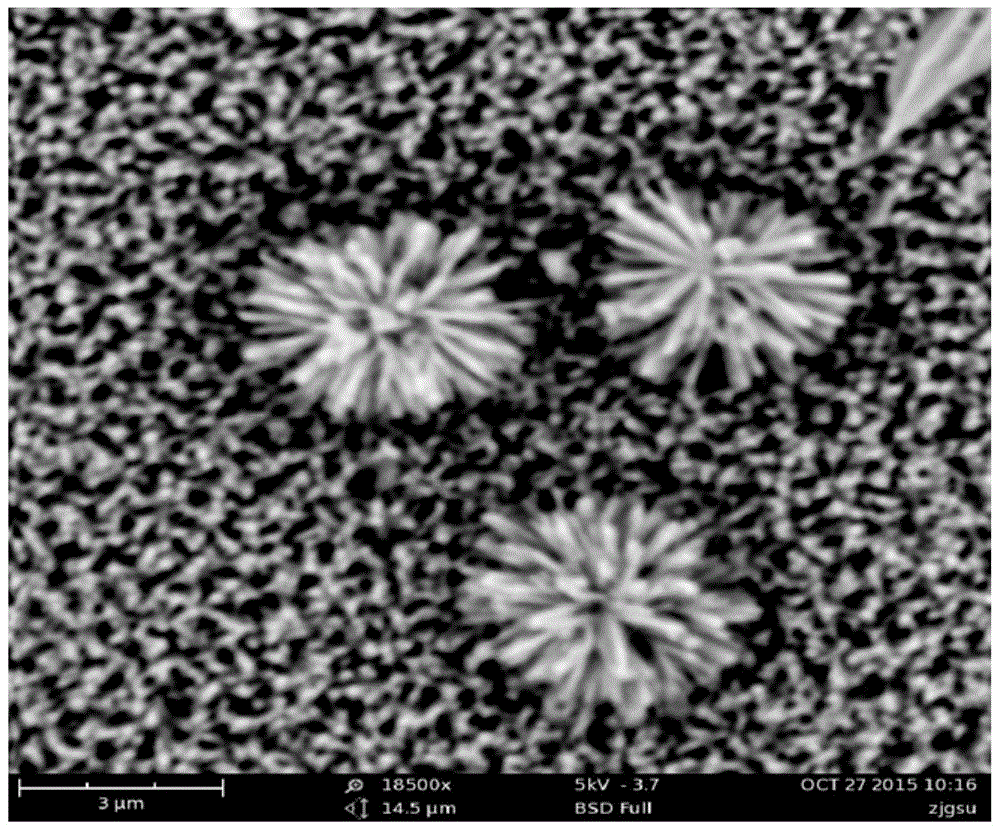

[0059] ① Concentrated hydrochloric acid and water were prepared at a ratio of 1:1 to make 50ml of hydrochloric acid solution. After stirring for 5 minutes, add 0.6ml of tetrabutyl titanate. After stirring for 10 minutes, pour it into the autoclave. Then put the FTO after ultrasonic cleaning with acetone / absolute ethanol / deionized water into the autoclave with the conductive surface facing upward at 45°.

[0060] ②Put the autoclave containing the reaction solution into an oven and continue heating at 170°C for 4 hours, and the obtained FTO loaded with white titanium dioxide is rinsed with absolute ethanol for use.

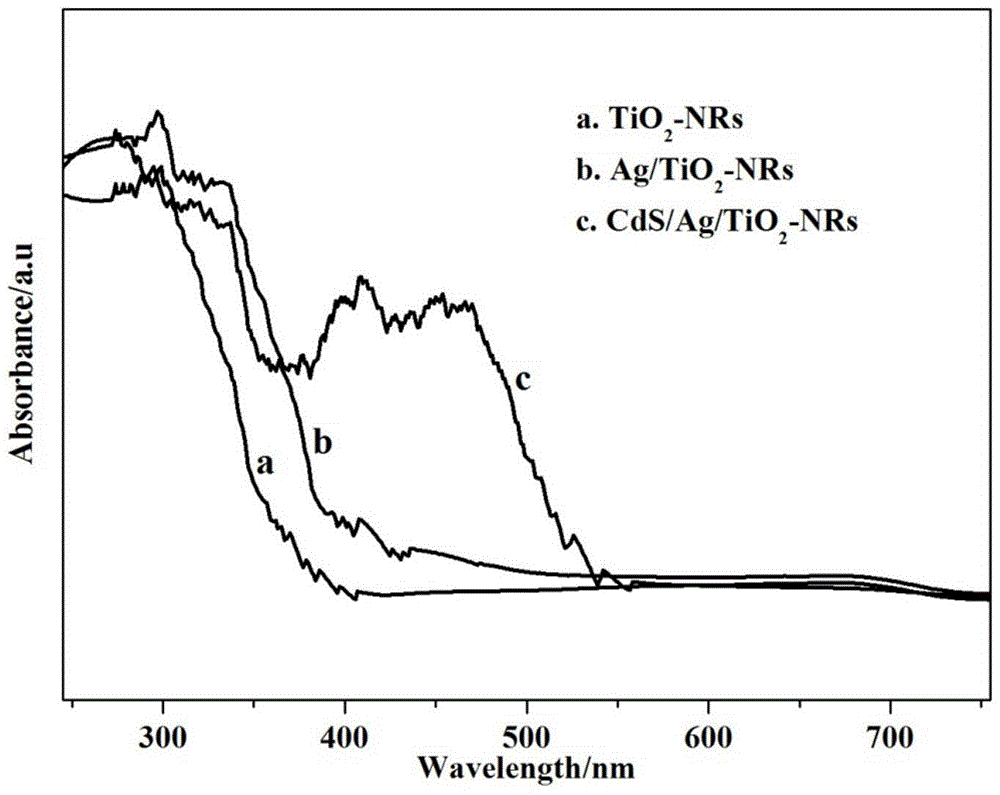

[0061] ③Prepare 0.1M silver nitrate solution and 0.15M sodium borohydride ethanol solution, soak the previously obtained electrode in the silver nitrate solution for 5 minutes, rinse with deionized water, blow dry with N2, and then put in sodium borohydride solution soak for 5 minutes, rinse with deionized water, and blow dry with N2. A titania nanoflower electrode...

Embodiment 2

[0074] In addition to putting the autoclave with the reaction solution into an oven as in step 2 of Example 1 and continuing to heat it for 3h / 5h / 7h respectively at 170°C, other methods were carried out as shown in Example 1, and the results were measured for 3h, The photocurrents of the electrodes obtained at 5h and 7h were 0.5, 0.85, and 0.4 times that of the composite electrode prepared in Example 1, respectively. The SEM pictures were basically the same as those in Example 1, and the hydrogen production was 0.6mL / h×cm 2 .

Embodiment 3

[0076] Except that the autoclave containing the reaction solution was put into an oven and heated at 150°C / 200°C for 4 hours respectively in step ② of Example 1, other methods were carried out as shown in Example 1, and the result was 150°C The photocurrent of the electrode prepared at 200°C and 200°C is 0.7 and 0.6 times that of the composite electrode prepared in Example 1, respectively, the SEM picture is basically the same as that in Example 1, and the hydrogen production is 0.7mL / h×cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com