Preparation method of catalyst capable of magnetic separation

A photocatalyst and magnetic separation technology, applied in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of catalyst activity influence, secondary pollution, reduction of catalyst utilization rate, etc., and achieve high-efficiency photocatalytic activity , the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

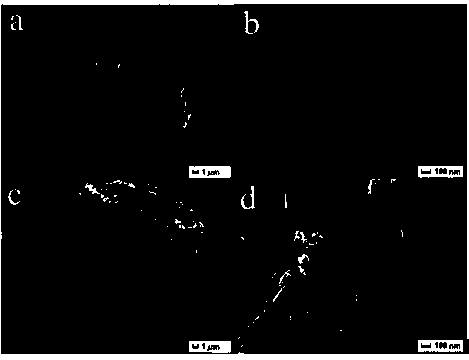

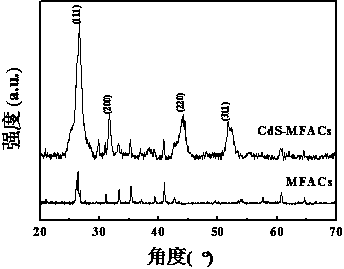

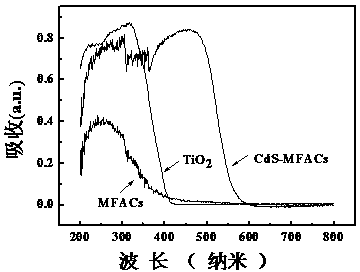

[0033] (1) Screening and modification of fly ash, use a 300-mesh sieve to remove oversized particles of fly ash with magnetic properties, weigh 5g of magnetic fly ash (MFACs) into a 250mL three-neck flask, add 120mL of 1M HCl solution. Keep the temperature at 80°C and mechanically stir the reaction for 3 hours. Suction filtration, washing with deionized water until neutral (pH=7), and vacuum drying at 30°C for 12 hours. Acid-activated magnetic fly ash is prepared. Then weigh 3g of acid-activated magnetic fly ash, 10g of APTES and 120.7mL of toluene, pass through nitrogen protection, keep the temperature at 70°C and react with mechanical stirring for 12 hours. Toluene and methanol were washed three times respectively, and vacuum-dried at 30°C for 12 hours to obtain amino magnetic fly ash (NH 2 -MFACs). Then take by weighing 2g amino magnetic fly ash and 3g succinic anhydride and add 49.2mLDMF again, mechanical stirring room temperature reaction 24 hours, DMF and ethanol eac...

Embodiment 2

[0040] (1) According to the method of Example 1 (1), the acid-activated magnetic fly ash was prepared. Then weigh 1g of acid-activated magnetic fly ash, 10g of APTES and 120.7mL of toluene, pass through nitrogen protection, keep the temperature at 70°C and react with mechanical stirring for 12 hours. Toluene and methanol were washed three times respectively, and vacuum-dried at 30°C for 12 hours to obtain amino magnetic fly ash (NH 2 -MFACs). Then take by weighing 0.5g amino magnetic fly ash and 3g succinic anhydride and add 49.2mLDMF again, mechanical stirring room temperature reaction 24 hours, DMF and ethanol each wash three times, 30 ℃ of vacuum drying 12 hours, make carboxyl magnetic fly ash (COOH -MFACs).

[0041] (2) To synthesize cadmium sulfide-magnetic fly ash photocatalyst, weigh 0.1g carboxyl magnetic fly ash and disperse it in 80ml water, then add 0.5g cadmium sulfate, 0.3g thiourea and 5g ammonia water. The reaction was carried out at 60° C. for 3 hours under ...

Embodiment 3

[0043] (1) According to the method of Example 1 (1), the acid-activated magnetic fly ash was prepared. Then weigh 5g of acid-activated magnetic fly ash, 10g of APTES and 120.7mL of toluene into nitrogen protection, keep the temperature at 70°C and react with mechanical stirring for 12 hours. Toluene and methanol were washed three times respectively, and vacuum-dried at 30°C for 12 hours to obtain amino magnetic fly ash (NH 2 -MFACs). Then take by weighing 3g amino magnetic fly ash and 3g succinic anhydride and add 49.2mL DMF again, mechanical stirring room temperature reaction 24 hours, DMF and ethanol each wash three times, 30 ℃ of vacuum drying 12 hours, make carboxyl magnetic fly ash (COOH- MFACs).

[0044] (2) Synthesis of cadmium sulfide-magnetic fly ash photocatalyst, weigh 1g of carboxyl magnetic fly ash and disperse in 80ml of water, then add 0.5g of cadmium sulfate, 0.3g of thiourea and 5g of ammonia water. The reaction was carried out at 60° C. for 3 hours under n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com