Method for enriching and recycling cadmium from lead smelting system

A lead smelting and enrichment technology, applied in the direction of improving process efficiency, can solve the problems of high production cost, difficult enrichment and separation, unreasonable economy, etc., and achieves short enrichment and separation process, efficient enrichment and separation, and economic benefits. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

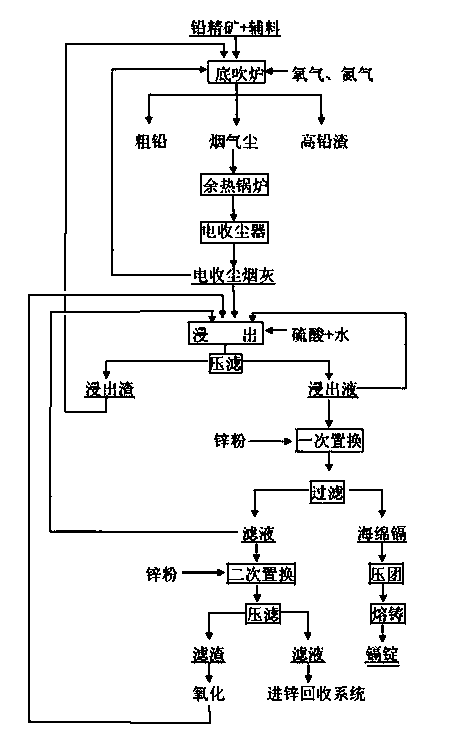

Image

Examples

Embodiment 1

[0040] Example 1: After 10 tons of lead concentrate is mixed with 0.5-1 tons of quartz, 0.5-1 tons of stones and 1-2 tons of low-cadmium smoke, it is added to the bottom blowing furnace, and the bottom of the furnace is blown into the furnace with an oxygen lance at a pressure of 0.6-1.0 Oxygen and nitrogen at MPa, where the amount of blown oxygen is 1200 m 3 , the amount of nitrogen is 0.3 times that of oxygen, and the temperature in the furnace is kept at 1100°C. After the reaction, high-lead slag, crude lead, and high-temperature SO2 flue gas dust are produced. After 280-350°C, 1 ton of ESP soot containing 20% cadmium is obtained after passing through the electrostatic precipitator; the obtained 1 ton of ESP soot containing 20% cadmium is added to water for leaching, and the leaching conditions : The liquid-solid ratio is 4:1, the temperature is about 30°C, and the time is 2 hours. After the leaching is completed, 0.7 tons of leaching residue and 4m of leaching solutio...

Embodiment 2

[0041] Example 2: Example 1: After 10 tons of lead concentrate is mixed with 0.5-1 tons of quartz, 0.5-1 tons of stones and 1-2 tons of low-cadmium smoke, it is added to the bottom blowing furnace, and the bottom of the furnace is blown into the pressure by an oxygen lance. Oxygen and nitrogen at 1MPa, the amount of oxygen blown into it is 1000 m 3 , the amount of nitrogen is 0.4 times that of oxygen, and the temperature in the furnace is kept at 1100°C. After the reaction, high-lead slag, crude lead, and high-temperature SO2 flue gas dust are produced. After 300°C, 1 ton of ESP soot containing 20% cadmium is obtained after passing through the electrostatic precipitator; the obtained 1 ton of ESP soot containing 20% cadmium is added to the concentration of 0.2-1% Leach in dilute sulfuric acid, leaching conditions: liquid-solid ratio 4:1, temperature around 30°C, time 2 hours. After the leaching is completed, 0.7 tons of leaching residue and 4m of leaching solution are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com