A kind of preparation method and application of agarose-bonded silica gel hybrid monolithic column

A technology for bonding silica gel and agarose, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of difficult preservation, easy to swell, etc., achieve good mechanical strength, improve hydrophilicity, and skeleton structure. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing an agarose-bonded silica gel hybrid monolithic column. The monolithic column uses a sol-gel method to mix tetramethoxysilane, agarose, polyethylene glycol, and urea in an ice bath to prepare a prepolymerized system, then put the pre-polymerization system into a quartz capillary to prepare an affinity monolithic column, and finally modify the affinity monolithic column in three steps to obtain an agarose-bonded silica gel hybrid monolithic column with amide groups on the surface.

[0024] The preparation method of the agarose-bonded silica gel hybrid monolithic column specifically comprises the following steps:

[0025] Step 1, oxidizing agarose, the oxidation process is: agarose is reacted for 6 hours in a nitric acid solution with a concentration of 3 mol / L, a reaction temperature of 70°C and light;

[0026] Step 2: Add urea and polyethylene glycol to the centrifuge tube, add oxidized agarose at the same time, stir evenly in an ice bath, then dro...

Embodiment 1

[0028] a) Capillary pretreatment

[0029] Cut off a certain length of capillary, rinse with water for 40 minutes, 1M NaOH for 80 minutes (forward flushing for 40 minutes and backflushing for 40 minutes to ensure that NaOH fills the entire capillary), plug both ends, and age at 40°C for 12 hours; then rinse with water for 40 minutes, 1M HCL for 80 minutes, and water Until the solution in the capillary becomes neutral; finally blow with nitrogen at 160°C for 6h.

[0030] 2) Oxidation treatment of agarose

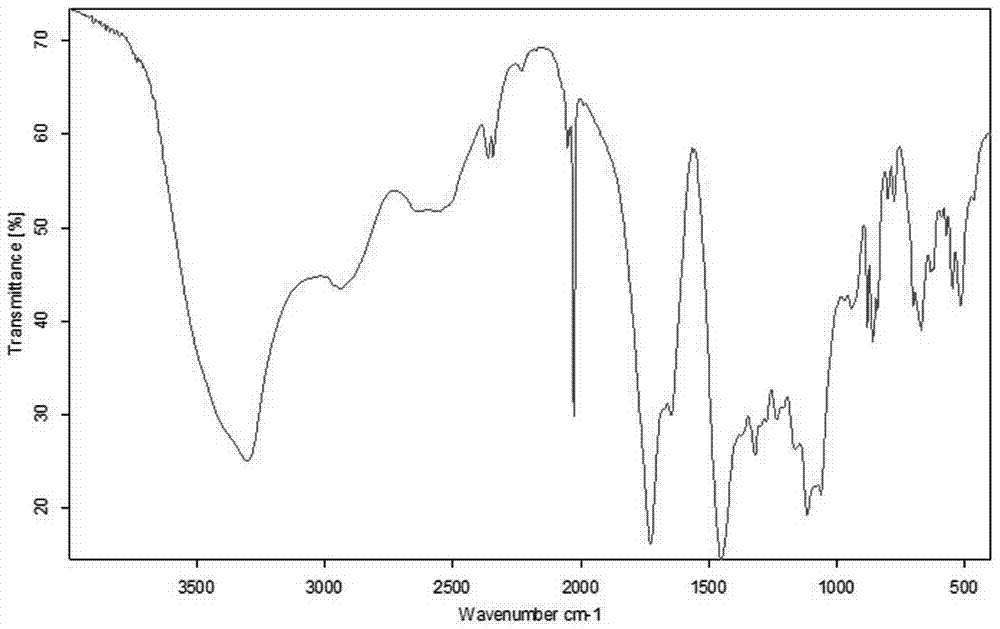

[0031] Accurately weigh 2.00g of agarose and 13ml of 3mol / L nitric acid, stir and react for 7h, and then oxidize the agarose. The infrared spectrum of the oxidized agarose is as follows: figure 1 shown.

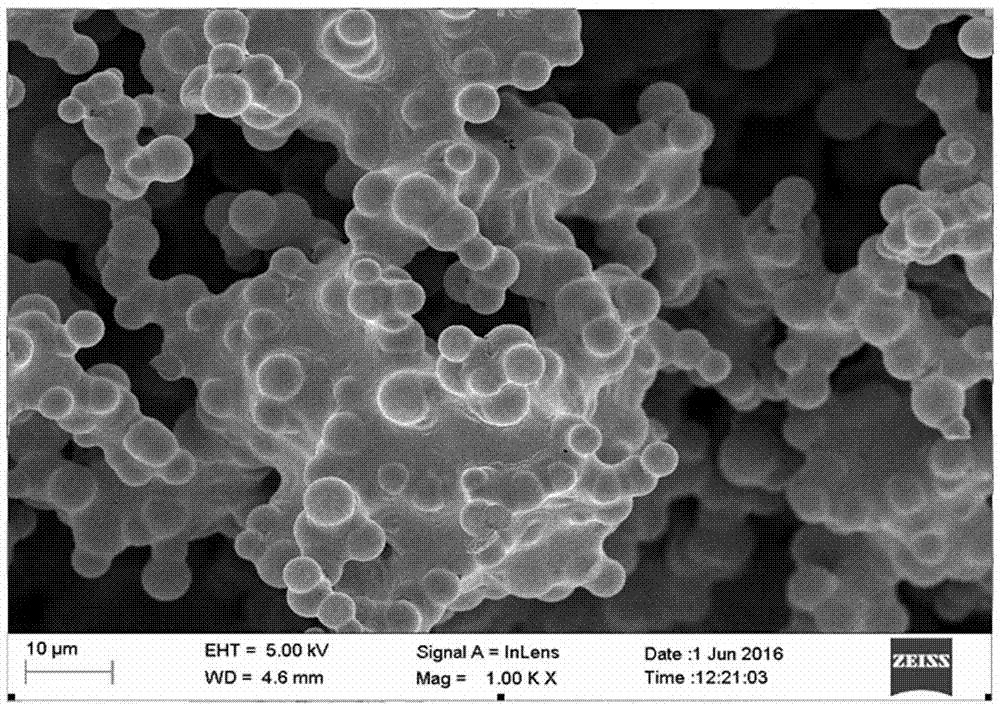

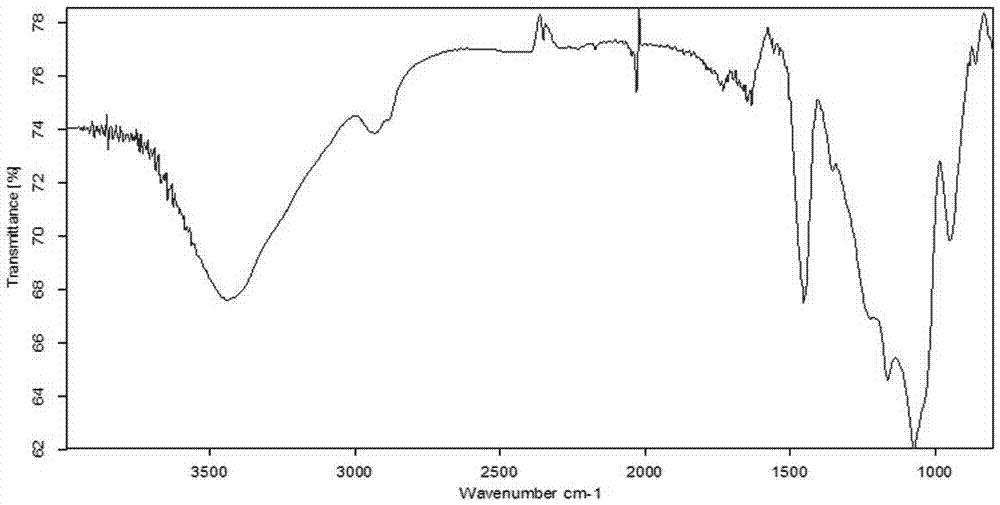

[0032] 3) Preparation of agarose-bonded organic-silica hybrid monolithic column

[0033] Accurately weigh 0.1706g of polyethylene glycol (PEG), 0.2504g of urea and mix with 3ml of nitric acid oxidized agarose solution, stir evenly in an ice bath, add about 1ml of 2 drops o...

Embodiment 2

[0039] Application of agarose-bonded silica hybrid monolithic column

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com