Method for preparing GO-CdS-ZnO-porous silicon composite photocatalyst

A technology of porous silicon and composite light, which is applied in the field of materials, can solve the problems of photocatalytic performance degradation and other problems, and achieve the effects of promoting effective separation and transmission, broadening the absorption range, and stabilizing the preparation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

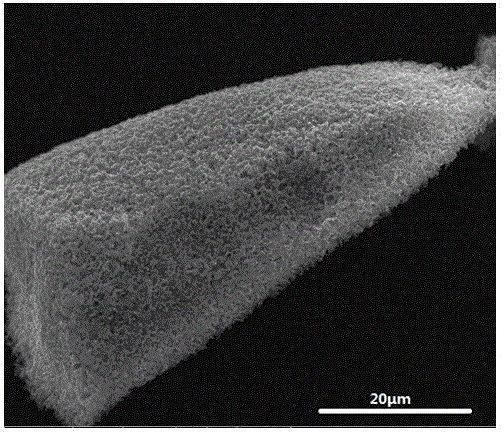

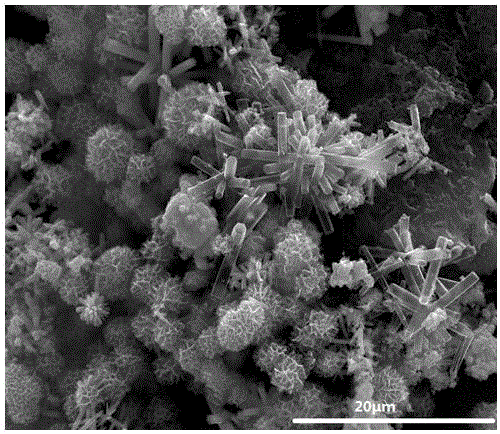

Embodiment 1

[0019] (1) Preparation of porous silicon: ①Pretreatment of silicon material: crush and grind the silicon material to a particle size of 1μm, wash with distilled water, and then soak the cleaned silicon powder with 1wt% HF for 60 minutes, and dry it for later use ② Etching of silicon powder: use chemical method to deposit Ag nanoparticles on silicon powder at room temperature, the deposition time is 15s, and place the silicon powder deposited with Ag nanoparticles on HF and H at 25℃ 2 O 2 Etch in the mixed solution, the concentration of HF in the mixed solution is 0.1mol / L, H 2 O 2 The concentration of Ag is 0.01mol / L, and the reaction system is stirred (180 revolutions / min) under dark conditions to obtain large-scale porous silicon particles containing nano-scale pores after 280 min; ③Removal of Ag nanoparticles: the porous silicon obtained in ② Place the particles in a nitric acid solution and soak for 1 min; ④Post-treatment of porous silicon particles: filter to obtain porous s...

Embodiment 2

[0025] (1) Preparation of porous silicon: ①Pretreatment of silicon material: crush and grind the silicon material to a particle size of 80μm, wash it with distilled water, then soak the cleaned silicon powder with 10wt% HF for 45 minutes, and dry it for later use ② Etching of silicon powder: Use chemical method to deposit Cu nanoparticles on silicon powder at room temperature, the deposition time is 30s, and put the silicon powder deposited with Cu nanoparticles on HF and H at 30℃ 2 O 2 Etch in the mixed solution, the concentration of HF in the mixed solution is 1mol / L, H 2 O 2 The concentration of Cu nanoparticles is 0.1mol / L, and the reaction system is stirred (180 revolutions / min) under dark conditions for 200 minutes to obtain large-scale porous silicon particles containing nano-scale pores; ③Removal of Cu nanoparticles: the porous silicon obtained in ② Place the particles in a nitric acid solution and soak for 50 minutes; ④Post-processing of porous silicon particles: filter ...

Embodiment 3

[0031] (1) Preparation of porous silicon: ①Pretreatment of silicon material: crush and grind the silicon material to a particle size of 300μm, wash it with distilled water, then soak the cleaned silicon powder with 20wt% HF for 30 minutes, and dry it for later use ② Etching of silicon powder: deposit Au nanoparticles on silicon powder by chemical method at room temperature, the deposition time is 55s, and place the silicon powder deposited with Au nanoparticles on HF and H at 35℃ 2 O 2 Etch in the mixed solution, the concentration of HF in the mixed solution is 5mol / L, H 2 O 2 The concentration of Au nanoparticles is 1mol / L, and the reaction system is stirred (180 revolutions / min) under dark conditions for 120 minutes to obtain large-scale porous silicon particles containing nano-scale pores; ③Removal of Au nanoparticles: the porous silicon particles obtained in ② Place it in a nitric acid solution and soak for 100 minutes; ④Post-treatment of porous silicon particles: filter to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com