Method for preparing nano-silver loaded tungsten trioxide with high photocatalytic activity

A catalytic activity, tungsten trioxide technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve difficult problems such as environmental friendliness, complicated preparation methods and processes, and the method is simple and easy to achieve , The effect of simple process operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: The preparation method of this embodiment comprises the following steps:

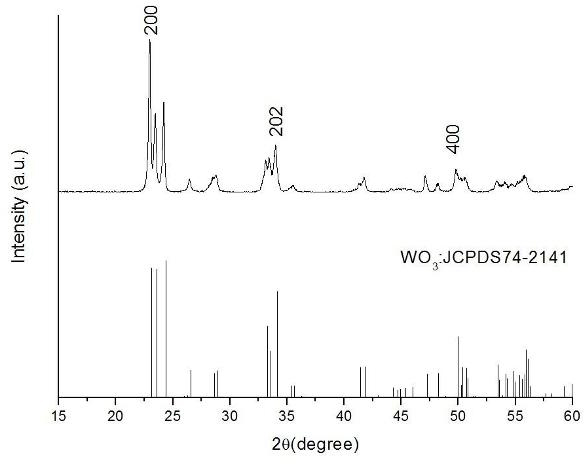

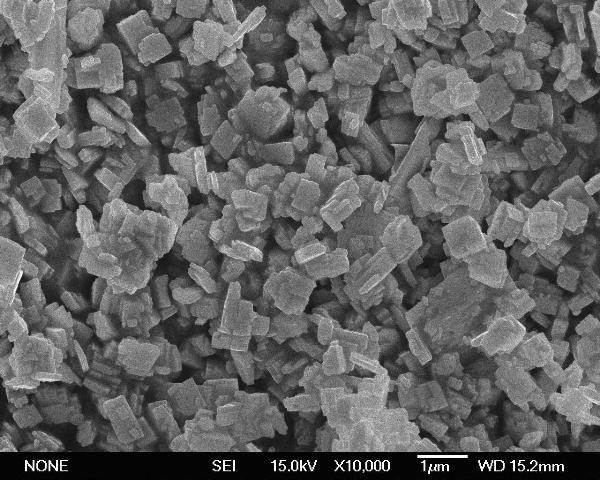

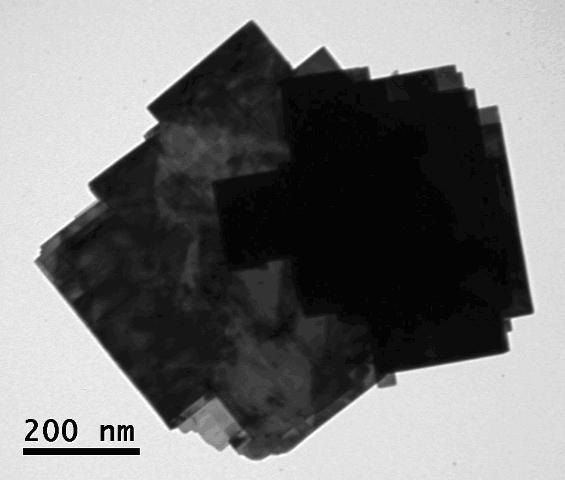

[0021] 1) Preparation of tungsten oxide flake nanomaterials: After dispersing and dissolving 3.5g of sodium tungstate in 20ml of deionized water by ultrasonic for 10-15 minutes, uniformly pass through the column filled with cation exchange resin, and control the exchange rate to 25 drops / min. Fully exchanged to obtain light yellow colloid of tungstic acid. After standing and aging for 18 hours, hydrothermally reacted at 160 degrees Celsius for 24 hours, washed with ethanol and deionized water for 3 times respectively, and obtained tungsten trioxide flake nanomaterials (see the attached figure 2 ).

[0022] 2) Ultraviolet light reduction: Accurately prepare 200 ml of silver nitrate solution with a mass concentration of 0.4%wt, add an appropriate amount of nitric acid until the solution is an acidic system with pH=1, and place it in an ultrasonic generator in the dark for 10 ...

Embodiment 2

[0025] Example 2: The preparation method of this embodiment comprises the following steps:

[0026] 1) Preparation of tungsten oxide flake nanomaterials: Disperse and dissolve 43.7g sodium tungstate in 250ml deionized water by ultrasonic for 60 minutes, then uniformly pass through the column filled with cation exchange resin, and control the exchange rate to 50 drops / min for full exchange , the light yellow colloid of tungstic acid was obtained. After standing and aging for 24 hours, hydrothermally reacting at 180 degrees Celsius for 24 hours, washing with ethanol and deionized water for 5 times respectively, to prepare tungsten trioxide flake nanomaterials.

[0027] 2) Ultraviolet light reduction: Accurately prepare 500 ml of silver nitrate solution with a mass concentration of 0.4%wt, add an appropriate amount of nitric acid until the solution is an acidic system with pH=1, and place it in an ultrasonic generator in the dark for 30 minutes for ultrasonic dispersion...

Embodiment 3

[0029] Example 3: The preparation method of this embodiment comprises the following steps:

[0030] 1) Preparation of tungsten oxide flake nanomaterial: same as the preparation of tungsten oxide flake nanomaterial in Example 1.

[0031]2) Ultraviolet light reduction: Accurately prepare 250 ml of silver nitrate solution with a mass concentration of 0.4%wt, add an appropriate amount of nitric acid until the solution is an acidic system with pH=1, and place it in an ultrasonic generator in the dark for 15 minutes for ultrasonic dispersion. Add the tungsten oxide flake nanomaterial prepared in step 1 to the above silver nitrate solution, and ultrasonically disperse it in an ultrasonic generator for 20 minutes, then place it under an ultraviolet lamp (wavelength 254nm) for 20 minutes, and finally obtain the product .

[0032] 3) Subsequent treatment: centrifuge the product and filter the supernatant by decantation, wash twice with ethanol and deionized water respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com